Silica powder production line

[Overview]: Silica powder (quartz powder) production line is a complete set of process equipment that processes quartz raw materials (quartz sand, quartz stone, etc.) into silicon dioxide powder with different particle sizes and purity requirements. Its core goal is to achieve efficient, precise, stable and environmentally friendly production.

[Production line advantages]: 1. Silica powder processing line is an organic combination of high-purity sand grinder crushing technology, ball mill grinding technology, and airflow classification technology, which can give full play to their respective technical advantages. 2. High Purity and Wear Resistance: The entire process utilizes ceramic or quartz protection, eliminating metal-to-metal contact and ensuring product purity while extending equipment lifespan. 3. Wear Resistance of Key Components: The classifying impeller uses high-polymer wear-resistant materials, significantly reducing wear. 4. Automated Operation: Supports fully automatic PLC control, completing grinding and packaging with a single click, saving labor costs. 5. Energy Saving and Environmental Protection: System optimization achieves low energy consumption, and a scientific dust removal design ensures dust control meets standards. 6. High-Quality and Stable Products: High purity, good whiteness, and uniform particle size, meeting quartz slab filler standards. 7. Customized and Stable Production Lines: Customized international standard production lines are available to meet specific needs, ensuring reliable operation.

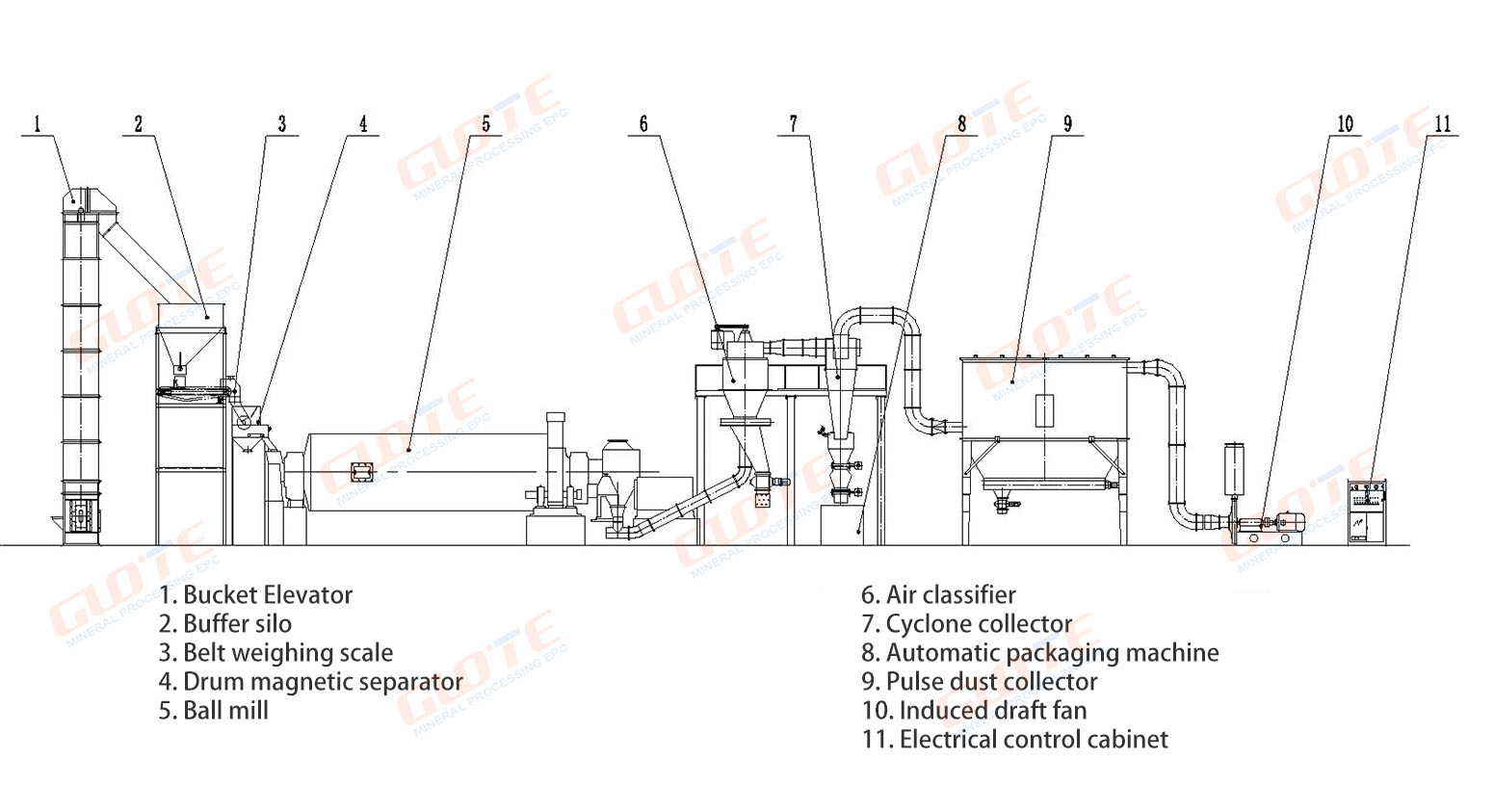

Process Description

-

01

Sand making and screening

Ore with a particle size of less than 400mm is fed by a loader into a vibrating screen, a feeder, and then into a sand grinder. The material produced by the sand grinder is separated by a separation screen to separate 40-mesh and 120-mesh finished products, and the coarse sand larger than 6-mesh is returned to the sand grinder for re-grinding.

-

02

Magnetic separation and grinding

After screening, the 5mm finer material passes through a bucket elevator and a buffer silo, and then enters a magnetic separator to remove magnetic impurities. The impurity-removed material enters a ball mill through a metering belt scale and is ground into fine powder.

-

03

Finished product classification

The ground material is classified into coarse and fine particle products by a classification system composed of airflow classifiers, cyclone collectors, pulse bag dust collectors, high-pressure induced draft fans and other equipment. The coarse particle products are returned to the ball mill through a belt conveyor for re-grinding, and the fine particles are collected as finished products.

-

04

Dust Removal

The entire system is a closed-loop system operating under negative pressure and equipped with a central dust collector. The gas discharged by the induced draft fan is clean gas that meets environmental protection requirements, and there is no dust spillage during the entire production process.

PROCESSING FLOW

Silica powder is made of natural quartz (SiO2) or fused quartz (amorphous SiO2 after natural quartz is melted at high temperature and cooled) through multiple processes such as crushing, ball milling, flotation, acid washing and purification, and high-purity water treatment.

Silica powder is a non-toxic, odorless, and pollution-free inorganic non-metallic material. Because of its excellent properties such as good temperature resistance, acid and alkali corrosion resistance, poor thermal conductivity, high insulation, low expansion, stable chemical properties, and high hardness, it is widely used in chemical, electronics, integrated circuits, electrical appliances, plastics, coatings, advanced paints, rubber, and other fields.

Ore (water washing and impurity removal) → crushing (sand grinder) → screening → magnetic separator (iron removal) → ball mill (grinding) → air flow classifier → finished product

(Key words:silica powder equipment manufacturer,silica powder processing,silica powder processing plant,silica powder production line,quartz powder processing plant)

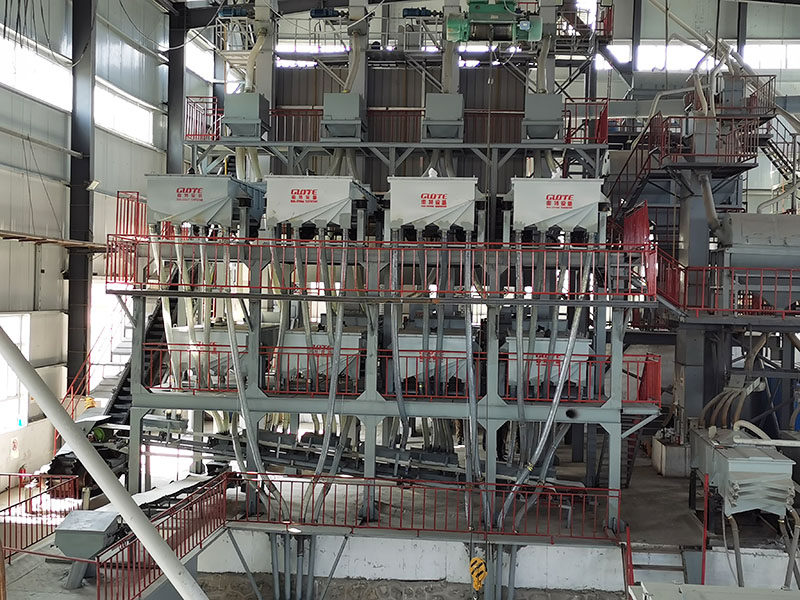

SUCCESSFUL CASE

RELATED PRODUCTS

RELATED NEWS

- 2024 Vietnam International Mining and Mineral Resources Recycling Exhibition

- Repair and maintenance of mining machinery and equipment.

- Process characteristics and process of quartz stone pickling

- Weifang Guote Mining Equipment Co., Ltd.

- What is a magnetic separator? What types of magnetic separators are there?

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE