Quartz slab sand production line

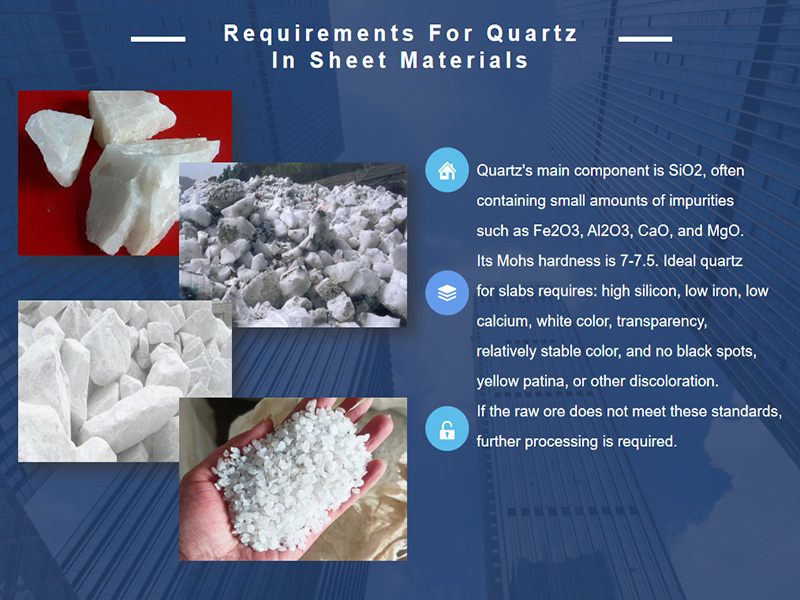

[Overview]: Quartz slabs, as an environmentally friendly composite material with extremely high hardness, are increasingly used in high-end urban decoration. The main raw materials constituting artificial quartz slabs are quartz slab sand and quartz powder. Quartz slab sand: In artificial quartz slabs, it is called aggregate, and the commonly used specifications are: 4-6 mesh, 6-8 mesh, 8-16 mesh, 16-26 mesh, 26-40 mesh, 40-70 mesh, 70-120 mesh, etc.; Quartz powder: In artificial quartz slabs, it is called filler, mainly used to fill the gaps formed between quartz sand particles, and the main specifications are: 325 mesh, 400 mesh, 800 mesh, 1250 mesh.

[Production line advantages]: For quartz sand and quartz powder used in artificial quartz slabs, Guote Equipment has developed an energy-saving and environmentally friendly dedicated production line for quartz slab sand. The characteristics of this production line are: high product purity, good whiteness, and elliptical particle shape. The equipment has ultra-pure internal protection, and a subsequent magnetic separator effectively solves the problems of equipment wear and product iron contamination. The entire production line system operates under negative pressure, ensuring no dust spillage during production, making it clean and environmentally friendly. The production line is centrally controlled, greatly reducing the labor intensity of workers and ensuring stable product quality.

Process Description

-

01

Crushing

Large quartz ore pieces are transported to the crushing section via belt conveyor. Depending on the ore's characteristics, 1-2 stages of crushing units are set up to break the ore into smaller particles.

-

02

Washing and Desliming

The crushed particles are conveyed to the washing and desliming process via belt conveyor. This process is mainly completed by a drum washing machine. The particles roll and rub inside the drum, removing surface-adhered mud, fine sand, and oxide scale. After being washed by water, they become clean quartz sand, discharged from the tail end of the machine, and transported by belt conveyor to a temporary storage yard for natural dewatering.

-

03

Grinding

The dewatered quartz sand particles are fed into the grinding hopper by a loader, and then evenly fed to a white belt conveyor (to avoid color contamination) by a vibrating feeder. They then enter a vertical crushing machine for grinding, obtaining fine quartz sand particles with a particle size of 4 to 120 mesh.

-

04

Screening and Impurity Removal

The ground particles enter a bucket elevator through the sand discharge port, and after being lifted, they are first screened by a drum screen. Qualified particles fall into a high-intensity magnetic separator, where weakly magnetic ferrous impurities are removed under a magnetic field of up to 10,000 GS.

-

05

Particle Size Sorting and Packaging

High-purity quartz sand is fed into a linear vibrating screen by a bucket elevator for particle size classification. Particles of different sizes are packaged into finished product bags. The entire grinding, screening, impurity removal, and particle size sorting process is carried out in a closed environment, and dust is collected by a pulse-jet bag filter, achieving dust-free production.

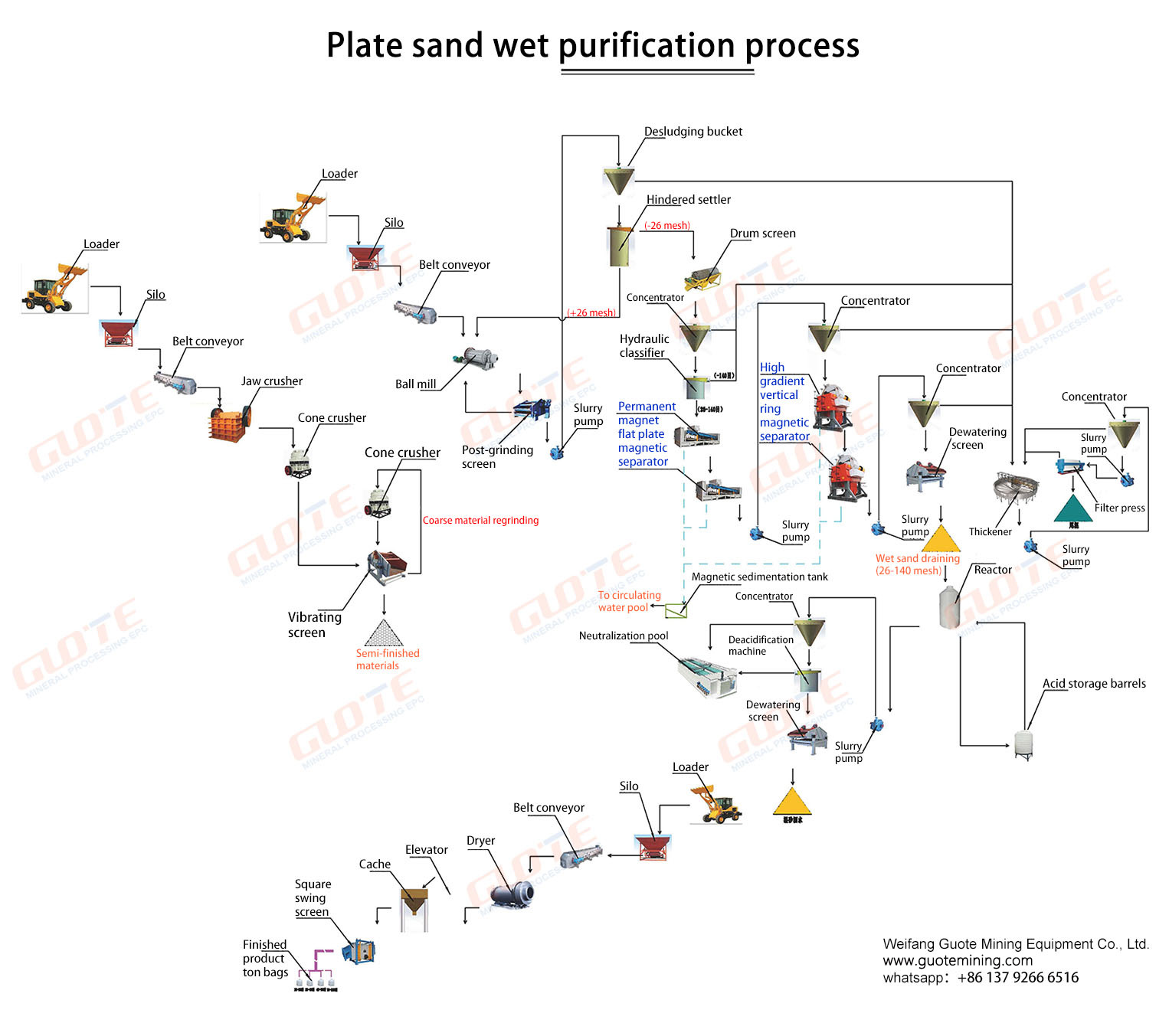

PROCESSING FLOW

Based on the client’s raw ore composition, site environment, and investment budget, Guote Equipment can customize a variety of personalized processing production lines. For quartz slab sand production lines, dry or wet processes can be selected (wet process production lines require a dryer); depending on site area and budget, vertical or horizontal slab sand production lines can be chosen; and regarding the purity of the raw ore, the need for a quartz acid washing process can be selected.

Guote Equipment will configure and plan a comprehensive EPC general contracting solution for you based on your specific circumstances, integrating mineral testing, plant design, equipment manufacturing and procurement, installation and commissioning, and after-sales service, to develop a complete and commercially viable feasible plan.

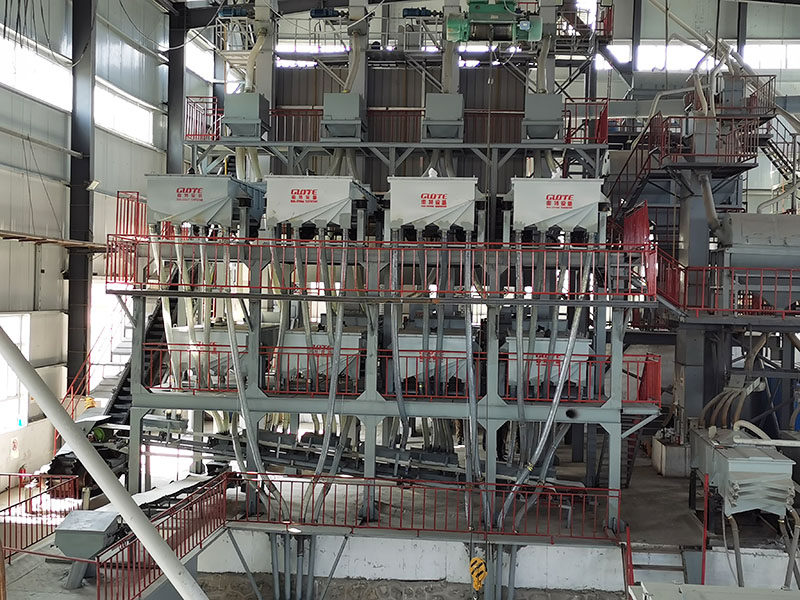

SUCCESSFUL CASE

RELATED PRODUCTS

RELATED NEWS

- Factors affecting the effect of mineral magnetic separation

- Repair and maintenance of mining machinery and equipment.

- Introduction to the main application areas of silicon powder

- Process characteristics and process of quartz stone pickling

- Weifang Guote Mining Equipment Co., Ltd.

- What is a magnetic separator? What types of magnetic separators are there?

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE