Quartz silica sand processing line

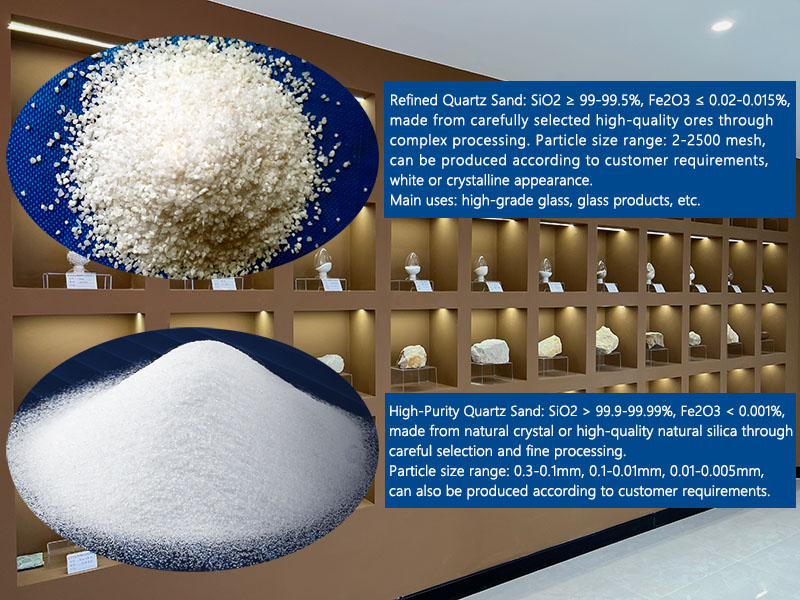

[Overview]: Silica sand processing line (Quartz glass sand production line) is an industrial system that specializes in producing high-purity quartz sand for glass, photovoltaic, electronics and other industries. According to the characteristics of raw materials and product requirements. The core goal is to reduce the iron content (Fe₂O₃) and control the particle size through crushing, magnetic separation, classification and other links.

[Production line advantages]: For silica sand used in industries such as glass and ceramics, Guote Equipment has developed an energy-saving and environmentally friendly wet silica sand process. This production line is characterized by: employing professionally designed equipment to significantly reduce energy consumption and achieve zero emissions of wastewater and dust; and boasting advantages such as high output, high purity, zero pollution, high automation, and stable and reliable process. Its core component is a magnetic separator, which removes magnetic impurities from the silica sand.

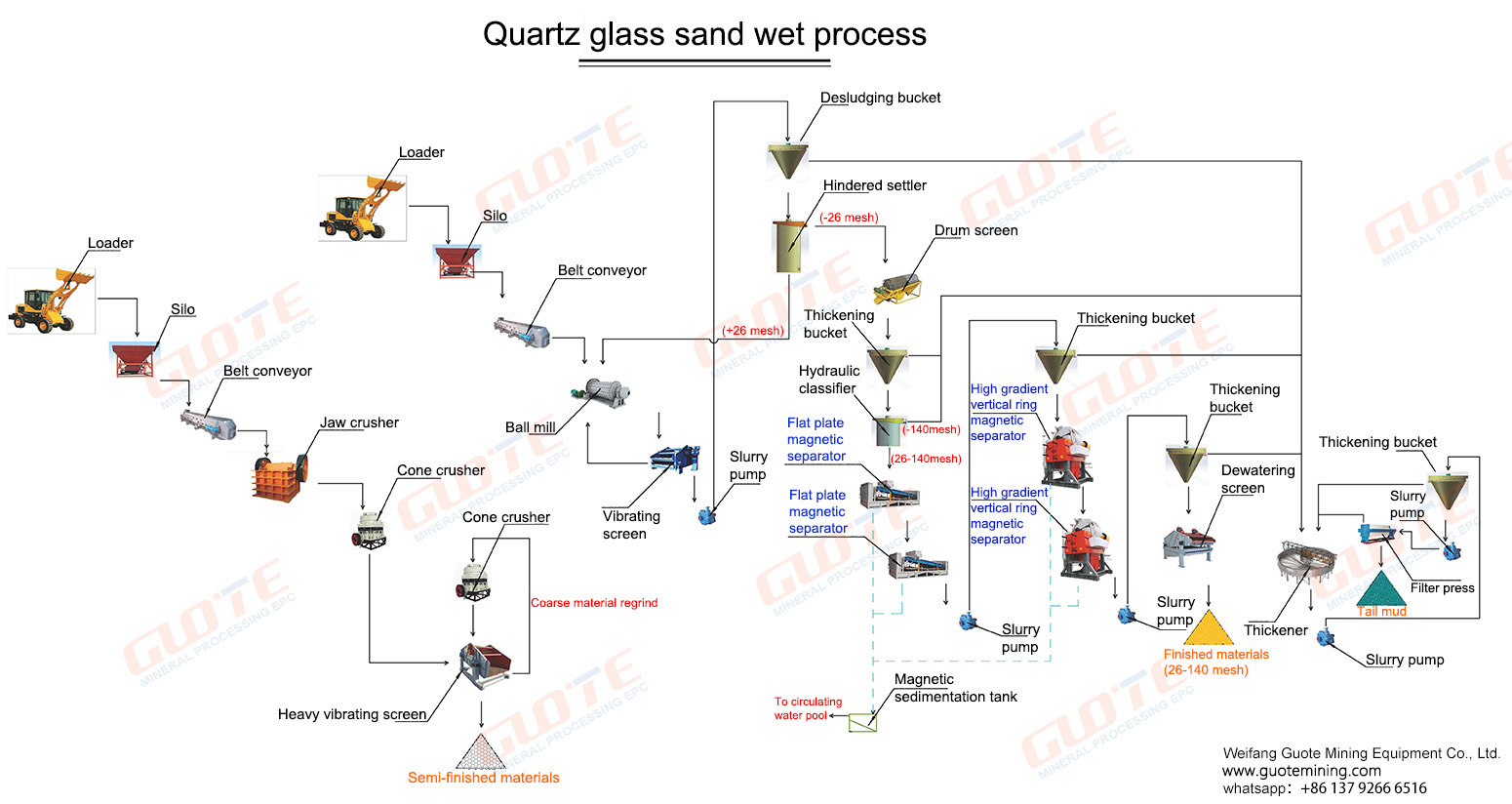

Silica sand processing production line: raw ore crushing → grinding and sand making → washing and desliming → screening and grading → magnetic separation → dewatering.

Process Description

-

01

Crushing and Grinding

First, according to the original ore's particle size, hardness,impurities and other characteristics,select 1 to 3 levels of crushing process to reduce the original ore particle size.The vibrating feeder feeds the large pieces of raw ore into the jaw crusher evenly and quantitatively for primary crushing.The crushed raw ore then enters the cone crusher to further reduce the particle size of the raw ore.Finally, the small pieces of raw ore fall into the vertical sand making machine for pre-grinding and are made into granular ore that meets the process requirements.Then it is lifted by the belt conveyor and enters the silo of the grinding process.The vibrating feeder at the bottom of the grinding silo vibrates the ore evenly into the high-frequency vibrating screen for preliminary selection.The large-particle ore sand on the screen enters the ceramic ball mill for grinding.

-

02

Desludging and Classification

The ground slurry is transported to the desludging bucket through a slurry pump for the first desludging and impurity removal process.The slurry with mud and sand impurities removed passes through the lower part of the desludging bucket and enters the hindered settlement machine for particle size classification.The equipment returns most of the unqualified ore pulp to the ceramic ball mill for re-grinding,and the qualified ore pulp is transported to the concentration bucket for the second desludging and impurity removal process.The raw ore slurry enters the hydraulic classifier from the concentrate port at the bottom of the thickening bucket.Under the combined effect of turbulence and gravity in the hydraulic classifier,the tailings are discharged into the tailings pond through the tailings pipeline at the top.

-

03

Magnetic Separation

Qualified raw ore pulp enters the magnetic separation and impurity removal process stage.First, the pulp enters the GTGB Permanent Magnet Wet Belt Magnetic Separator,which is a patented product of the company and can efficiently separate most magnetic impurities.The pulp after impurity removal enters the GTLH Wet High Intensity Magnetic Separator.Under the action of the extremely strong induction magnetic field of up to 20000 Gauss,the fine-grained weak magnetic impurities in the pulp are completely separated and enter the tailings pond through the slag discharge pipeline.The concentrate slurry is pumped into the thickening bucket by the slurry pump for thickening and dehydration process.The concentrate slurry after preliminary concentration enters the vibrating dewatering screen.Finally,the dried and qualified concentrate is sent to the finished product silo,waiting to be packaged and shipped out of the factory.

-

04

Tailings Treatment

All tailings generated in the entire quartz and feldspar wet production line are collected and sent to the tailings treatment process.First, the tailings slurry is discharged into a thickening tank with a thickener.After being clarified by the thickener,the beneficiation water is discharged from the overflow tank,and the concentrated tailings slurry is discharged from the central discharge port.Then the tailings are pumped to the ceramic filter for the final dehydration process.The ceramic plate group covered with micropores separates the solid and liquid of the tailings slurry. The separated water can be reused as mineral processing water. The tailings sludge is sent to the tailings yard by the belt conveyor.

PROCESSING FLOW

As a bright new star of non-metallic mineral materials, quartz sand has only a short development history of more than ten years, but it has been widely used in traditional fields such as ceramics and glass, building materials, enamel, chemicals, casting, fireproof materials, etc. Moreover, due to the unique physical and chemical properties of quartz sand, it occupies a pivotal position in aviation, aerospace, electronics, machinery and today’s rapidly developing IT industry.

When planning and configuring a silica sand production line, there are several key points to consider:

1. Clearly define product positioning: Product positioning directly determines the complexity and investment scale of the production line. For example, producing photovoltaic glass or electronic-grade high-purity quartz sand requires extensive purification processes such as high-intensity magnetic separation (even high-gradient magnetic separation), flotation, and acid washing.

2. Focus on environmental protection and energy conservation: Selecting equipment equipped with dust removal and noise reduction devices, as well as comprehensive wastewater treatment and recycling systems, has become standard for modern production lines.

3. Consider integration and automation: Prioritize equipment with a high degree of integration, which helps save space, reduce energy consumption, and facilitate management.

4. Consider investment and operating costs: While meeting process requirements, comprehensively compare equipment price, energy consumption, durability, and maintenance costs to select the option with the best value for money.

(Key words: Quartz sand processing plant,Quartz purification,Quartz sand production line,Quartz glass sand production line,Silica sand processing,Silica sand purification.)

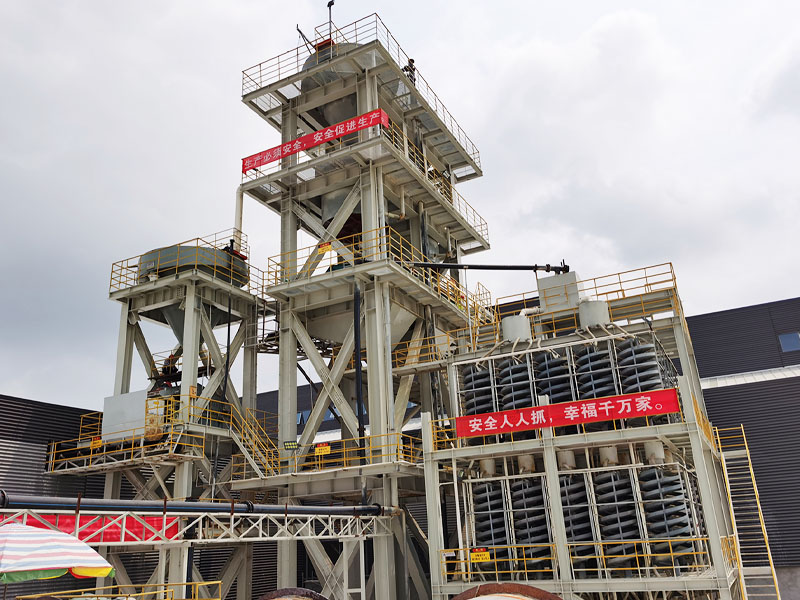

SUCCESSFUL CASE

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE