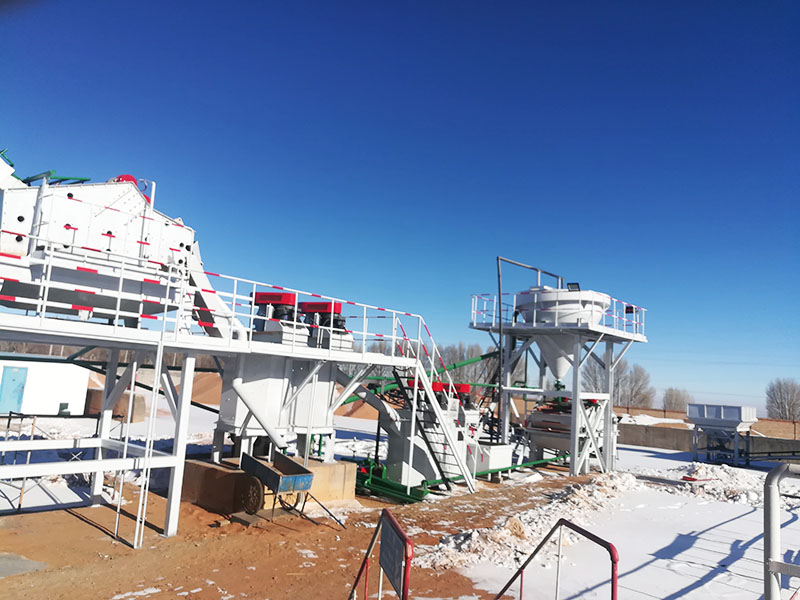

Petroleum fracturing sand production line

[Overview]: The petroleum fracturing sand production lines are indispensable core material preparation systems in the oil and gas extraction industry. They focus on transforming natural quartzite raw materials into high-quality proppant with high strength, high sphericity, and low impurities through a series of precision processes. This product plays a crucial role in hydraulic fracturing, effectively embedding itself into rock fractures and maintaining their long-term conductivity, thereby significantly improving oil and gas recovery efficiency.

[Production line advantages]: Our company's independently developed spherical sand oil fracturing sand production line excels in several key performance aspects: it possesses large-scale continuous production capacity, operates efficiently and stably, and significantly reduces unit energy consumption and maintenance costs; through optimized sand preparation and grading processes, the produced proppant particles are uniform in size, have smooth sphericity, and a clean surface, better meeting the stringent requirements of deep fracturing conditions and providing customers with reliable, high-performance fracturing sand products.

Process Description

-

01

Crushing and Pre-screening

The raw ore (diameter ≤400mm) is first coarsely crushed by a jaw crusher, then finely crushed by a cone crusher, and finally shaped by a vertical shaft impact crusher to form particles with a diameter range of 0.425–0.85mm, ensuring a sphericity >0.8. Afterwards, materials with excessively large particle sizes (e.g., >20 mesh) are separated by a vibrating screen and returned to the crushing system for reprocessing.

-

02

Scrubbing and magnetic separation

Two-stage washing is performed using a spiral sand washer, drum sand washer, or vertical washer, controlling the turbidity ≤100 FTU to effectively remove clay and surface impurities. The washed ore sand enters a high-gradient magnetic separator, undergoing two-stage magnetic separation to achieve a weak magnetic impurity removal rate >90%, ensuring the Fe₂O₃ content in the final product is ≤0.015%.

-

03

Dehydration and drying

Qualified slurry undergoes preliminary dewatering via a dewatering screen, followed by drying in a rotary dryer at 90–120℃ for 25–30 minutes, reducing the moisture content to ≤0.5%.

-

04

Screening and Grading

Finally, the slurry is precisely screened using a square swing screen to obtain products with a target particle size of 0.425–0.85 mm, ensuring that the sphericity of the finished sand is ≥0.9, meeting the quality standards for oil fracturing sand.

PROCESSING FLOW

Fracturing proppants are widely used in fracturing transformation of deep wells and high-pressure oil and gas layers. This product is refined using high-quality natural quartz sand as raw material and has the advantages of high compressive strength, low density, good sphericity, high smoothness, and strong conductivity. Practice has proved that the use of quartz sand proppants in oil well fracturing can increase production by 30-50% and extend the service life of oil and gas wells.

When planning and configuring a silica sand production line, there are several key points to consider:

1. Clearly define product positioning: Product positioning directly determines the complexity and investment scale of the production line.

2. Focus on environmental protection and energy conservation: Selecting equipment equipped with dust removal and noise reduction devices, as well as comprehensive wastewater treatment and recycling systems, has become standard for modern production lines.

3. Consider integration and automation: Prioritize equipment with a high degree of integration, which helps save space, reduce energy consumption, and facilitate management.

4. Consider investment and operating costs: While meeting process requirements, comprehensively compare equipment price, energy consumption, durability, and maintenance costs to select the option with the best value for money.

SUCCESSFUL CASE

RELATED PRODUCTS

RELATED NEWS

- 2024 Vietnam International Mining and Mineral Resources Recycling Exhibition

- Repair and maintenance of mining machinery and equipment.

- Process characteristics and process of quartz stone pickling

- Weifang Guote Mining Equipment Co., Ltd.

- What is a magnetic separator? What types of magnetic separators are there?

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE