Manganese ore processing line

[Overview]: Manganese ore beneficiation production lines are the core process for processing manganese ore to meet industrial application standards. Industrially valuable manganese minerals mainly include pyrolusite, diaspore, and rhodochrosite, with a manganese content generally ranging from 50% to 70%, serving as the primary raw materials for manganese extraction and the preparation of manganese-based products.

[Production line advantages]: For this field, Guote Equipment provides efficient integrated production line solutions with five major advantages: 1. Highly efficient resource utilization. Through pre-waste removal and fine sorting processes, low-grade ore is effectively processed, improving recovery rates. 2. Flexible process customization. Modular design adapts to various manganese ore properties, allowing for flexible process adjustments to ensure stable production. 3. Significant energy savings and efficiency gains. Pre-waste removal reduces energy consumption, while efficient sorting improves product grade and value, resulting in outstanding overall benefits. 4. Intelligent and green operation. Integrated automatic control and online monitoring, equipped with an environmental protection system, achieve intelligent management and clean production. 5. Full-cycle service guarantee. Providing full-chain support from design to operation and maintenance, ensuring rapid production ramp-up and long-term stable operation.

Process Description

-

01

Crushing and Screening.

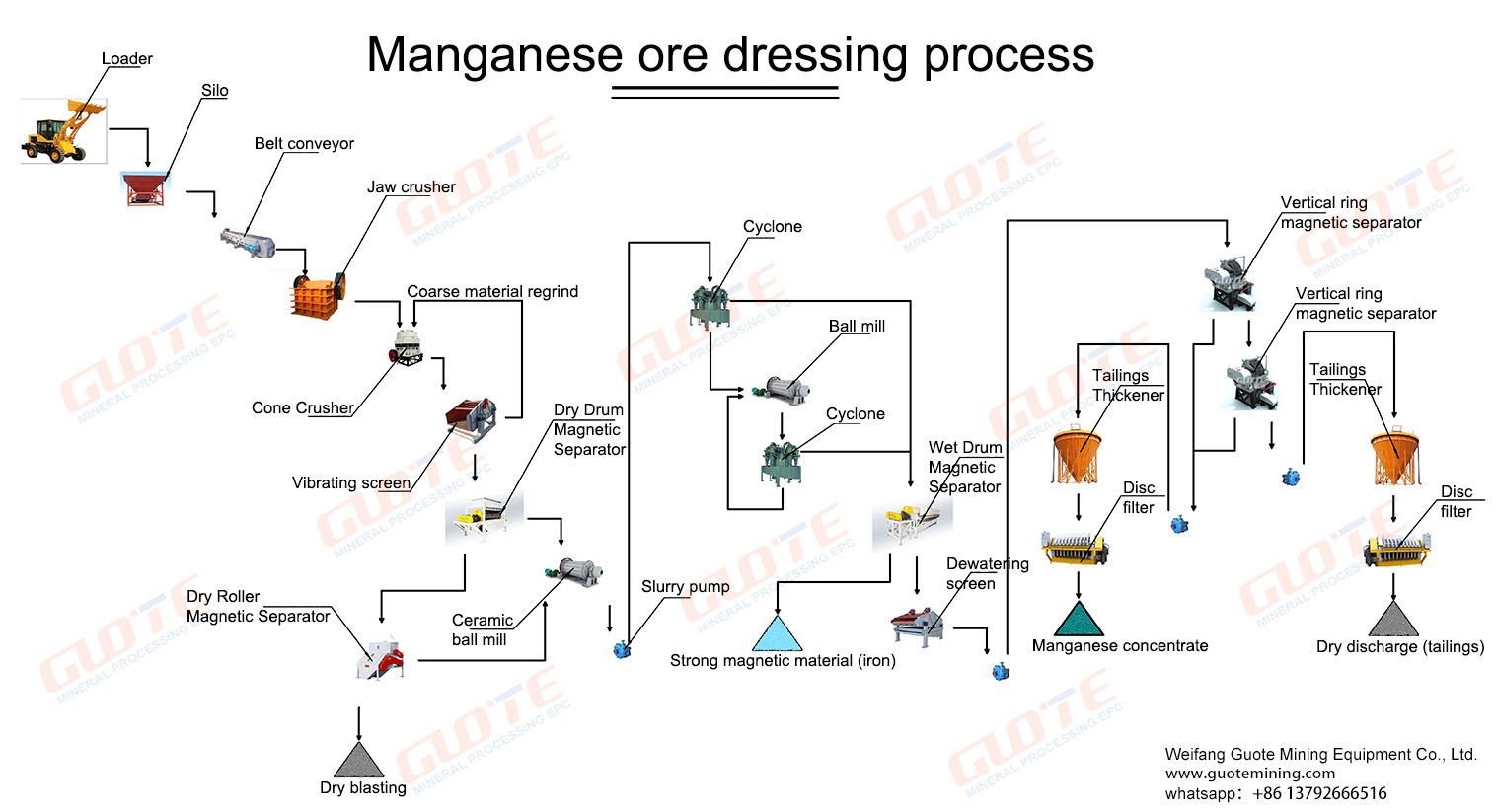

The large manganese ore is sent to the jaw crusher by the vibrating feeder through the silo for coarse crushing; the coarsely crushed manganese ore is screened by the vibrating screen and sent to the single-cylinder hydraulic cone crusher by the belt conveyor for medium crushing; the manganese ore after medium crushing is sent to the multi-cylinder hydraulic cone crusher for fine crushing.

-

02

Dry throwing.

The crushed manganese ore is sent to the permanent magnetic drum magnetic separator for preliminary magnetic separation, the concentrate enters the next process, the tailings enter the permanent magnetic high-field strength roller magnetic separator for secondary magnetic separation, the tailings are discarded, and the concentrate enters the next stage.

-

03

Grinding.

After dry throwing, the manganese ore is evenly fed into the mill for grinding, and then the slurry pump pumps the ore slurry into the first cyclone for coarse and fine separation. The fine material overflows into the next process, and the coarse material enters the second mill. After being ground by the second mill, it enters the second cyclone for coarse and fine separation. Similarly, the fine material enters the next process, and the coarse material returns to the second mill to form a closed loop.

-

04

Ore dressing.

The manganese ore powder with the required particle size is sent to the wet permanent magnetic separator for medium magnetic separation to remove the mechanical iron in the slurry, and then enters the vibrating safety screen to prevent large materials from entering the next process section. The slurry is then driven into the high-gradient vertical ring magnetic separator for strong magnetic sweeping to separate the manganese ore powder from the tailings to obtain manganese concentrate slurry, which is then driven into the manganese ore thickening tank. The tailings then enter the second-stage high-gradient vertical ring magnetic separator for secondary strong magnetic sweeping to obtain swept manganese concentrate. The manganese concentrate slurry is also driven into the thickening tank for preliminary concentration and dehydration, and then enters the disc filter to separate the concentrate from water. The dehydrated manganese concentrate is transported to the finished product warehouse; the tailings after sweeping enter the tailings thickening tank, and after concentration, they enter the disc filter for mud and water separation. The filter dehydrates the mud and enters the stockpile.

PROCESSING FLOW

From bulk ore to finished manganese concentrate, we use advanced technology to achieve efficient conversion, maximize purification recovery rate, and create visible benefits for you; intelligent control throughout the process, stable and reliable quality, ensure your worry-free raw material supply; lean production line to achieve low-cost, high-efficiency concentrate output, help you quickly improve your market competitiveness.

The manganese ore production line constructed by our company has low investment and high efficiency. It can implement customized construction according to the customer’s site conditions and budget to ensure worry-free throughout the process.

SUCCESSFUL CASE

RELATED SOLUTIONS

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE