Iron ore processing line

[Overview]: Iron ore processing line is the core process for handling iron ore, enabling it to meet industrial application standards. Industrially valuable iron minerals mainly include strongly magnetic magnetite and weakly magnetic ores such as hematite and limonite, with iron content typically ranging from 20% to 65%. They are the basic raw materials for steel smelting and various iron products.

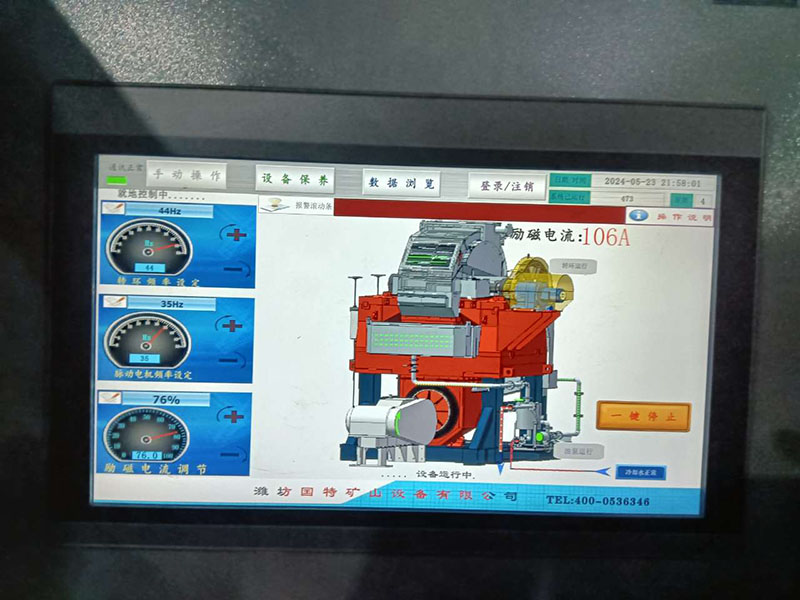

[Production line advantages]: Guote Equipment provides efficient complete line solutions with five major advantages: 1. Highly efficient resource utilization: Through pre-waste removal and multi-stage separation, the iron recovery rate of low-grade and complex symbiotic ores is improved; 2. Flexible process customization: Modular design can adapt to different ores, with optimized magnetic separation, gravity separation, and flotation processes for magnetite, hematite, etc.; 3. Significant energy saving and efficiency improvement: Pre-waste removal reduces grinding and beneficiation energy consumption, and efficient separation improves concentrate grade and metal recovery rate; 4. Intelligent and green operation: Utilizing automated control and online monitoring, and equipped with environmental protection facilities to achieve clean production; 5. Full-cycle service guarantee: Covering design, manufacturing, commissioning to operation and maintenance support, ensuring stable and efficient project operation.

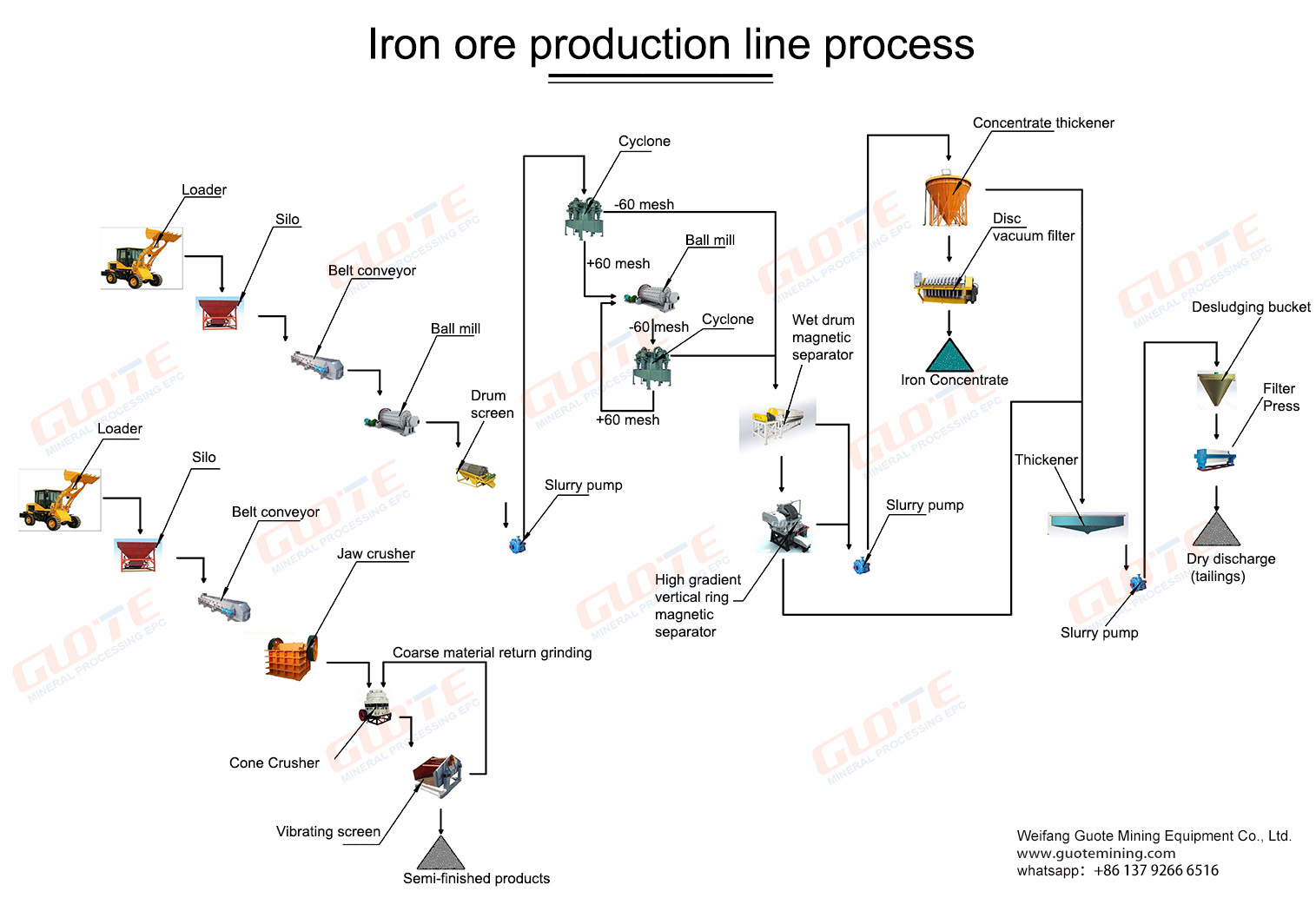

Process Description

-

01

Crushing the raw iron ore.

After blasting, during the iron ore mining process, excavators and loaders transport large pieces of raw iron ore to the iron ore crushing production line. Large pieces of iron ore are evenly fed into the jaw crusher (primary crushing) through the silo by the vibrating feeder for coarse crushing; then the coarsely crushed iron ore is vibrated and screened, and then sent to the single-cylinder hydraulic cone crusher (secondary crushing) by the belt conveyor for medium crushing; the iron ore material after medium crushing is sent to the multi-cylinder hydraulic cone crusher for fine crushing. Finally, the finely crushed raw ore is screened by the vibrating screen, and the iron ore with qualified particle size enters the next stage.

-

02

Grinding iron ore particles.

The 0-12mm iron ore particles screened by the vibrating screen (produced by the first step-iron ore crushing-the last stage) are evenly fed into the ball mill for grinding, and the powder is screened by the post-grinding screen. Among them, the iron ore powder that does not meet the requirements is sent back to the ball mill for further grinding; the ore powder that meets the requirements of the next level of production is sent to the next section.

-

03

Purify and remove impurities from the iron ore powder.

The iron ore powder that meets the requirements after the second grinding not only contains the iron required for production, but also contains various other metal ores and gangue. At this time, according to the analysis materials of the original ore, the iron ore magnetic separation equipment can be used to purify the iron ore by strong magnetic separation, weak magnetic separation (such as: vertical ring magnetic separator, wet magnetic separator) and other magnetic separation.

-

04

Drying.

The iron ore after the iron ore magnetic separation process basically meets the commercial demand. At this time, by drying it with a dryer, the high-quality iron concentrate required for production can be achieved.

-

05

Water treatment.

The whole process is equipped with a thickener, and all pollution-free system water is input into the thickener. The thickener precipitates the mud, and the precipitated water overflows into the clear water tank for reuse. The precipitated mud is pumped into the filter through the slurry, and the filter dehydrates the mud and enters the pile shed for stacking.

PROCESSING FLOW

For the comprehensive processing of iron ore and tailings, Guote offers customized, highly efficient end-to-end solutions, leveraging advanced technology to help clients maximize resource value.

Our production line designs prioritize a balance between capital efficiency and operational effectiveness. We provide flexible and configurable construction plans tailored to your specific site conditions and investment budget, ensuring seamless integration from planning to commissioning and eliminating any concerns.

From large ore blocks to high-quality iron ore concentrate, we utilize cutting-edge sorting and purification technologies to achieve efficient conversion and significantly improved recovery rates of ore resources, thereby creating sustained and substantial economic returns for our clients. The entire line employs an intelligent control system, ensuring stable and reliable production processes and consistent quality, guaranteeing a secure and controllable raw material supply.

Through lean design and intelligent operation, this production line maintains high production capacity while achieving low operating costs, effectively enhancing the market competitiveness of concentrate products and helping clients quickly gain a competitive edge in the industry.

SUCCESSFUL CASE

RELATED SOLUTIONS

RELATED PRODUCTS

RELATED NEWS

- 2024 Guote Mining Equipment Promotional Film

- 2024 Vietnam International Mining and Mineral Resources Recycling Exhibition

- Repair and maintenance of mining machinery and equipment.

- Process characteristics and process of quartz stone pickling

- Weifang Guote Mining Equipment Co., Ltd.

- What is a magnetic separator? What types of magnetic separators are there?

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE