Quartz pickling process line

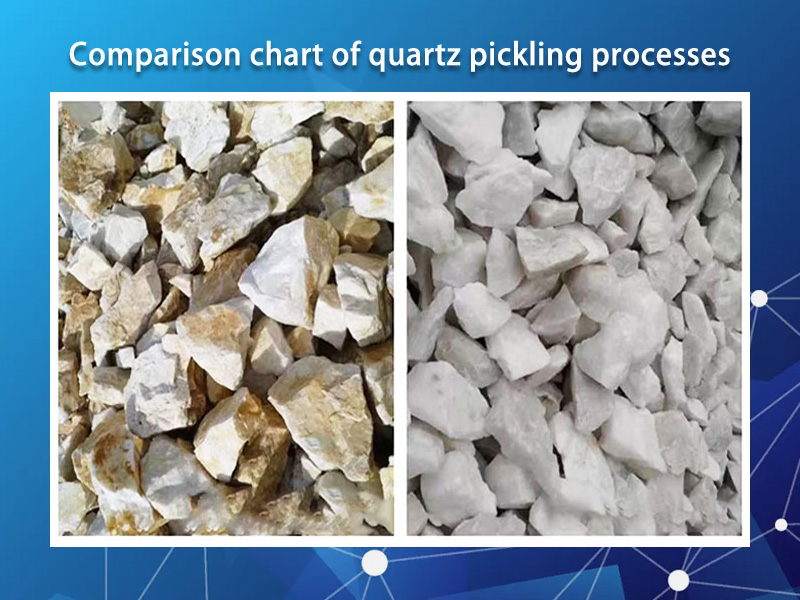

[Overview]: Impurities in quartz ore can severely affect product performance: transition metals such as iron reduce the light transmittance and electrical conductivity of quartz; excessive content of alkali metals such as potassium and sodium impairs its high-temperature resistance, thermal stability, and optical properties. Generally, the lower the silicon content, the higher the impurity content. In existing purification technologies, acid washing is a crucial step in removing impurities and improving purity.

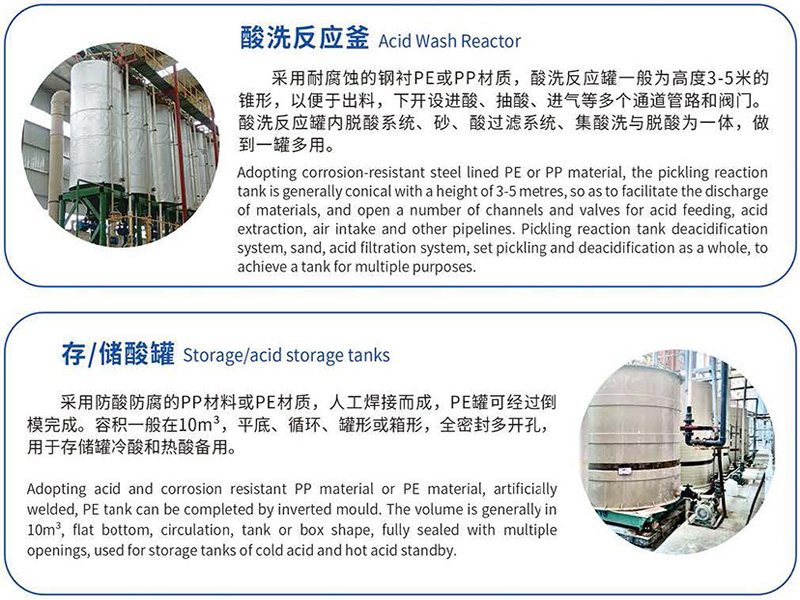

[Production line advantages]: Quartz acid washing equipment is specifically designed to remove surface impurities (such as yellow rind, oxide scale, and black rind) from quartz blocks and sand. The advantages of this process include: corrosion-resistant tanks made of PE or PPH material, providing insulation and durability; an environmentally friendly formula ensuring no discoloration or yellowing after cleaning; a dynamic process that shortens reaction time and significantly improves impurity removal; integrated acid washing, deacidification, and cleaning, resulting in a small footprint and low cost; recyclable acid and water, eliminating external pollution; and the entire process can be completed within 24 hours, effectively increasing silicon content and reducing impurities.

Process Description

-

01

Material Preparation and Feeding

The raw ore is temporarily stored in a silo and then continuously fed into a dedicated pickling reactor via a conveyor belt.

-

02

Pickling Reaction

Inside the reactor, the material reacts fully with an environmentally friendly formulated acid solution (hydrofluoric acid, oxalic acid, etc., can be selected according to customer requirements) at a set temperature. During the reaction, the acid solution circulates, and optimal reaction conditions are maintained through a heating and temperature control system, thereby removing impurities such as yellow scale, oxide scale, and black scale from the quartz surface. The reactor uses environmentally friendly insulation materials with excellent corrosion resistance.

-

03

Deacidification and Washing

The pickled quartz sand sequentially enters a deacidification hopper, deacidification machine, and dewatering screen for deacidification, washing, and dewatering treatment, yielding clean, high-quality sand, which is then transported to the finished product warehouse for storage.

-

04

Wastewater Treatment and Recycling

The separated residual acid solution is transported to a neutralization mixing tank and neutralized by adding industrial alkali. After neutralization and sedimentation, the supernatant overflows into the clear water tank and is reused as circulating water in production, achieving zero wastewater discharge and resource recycling.

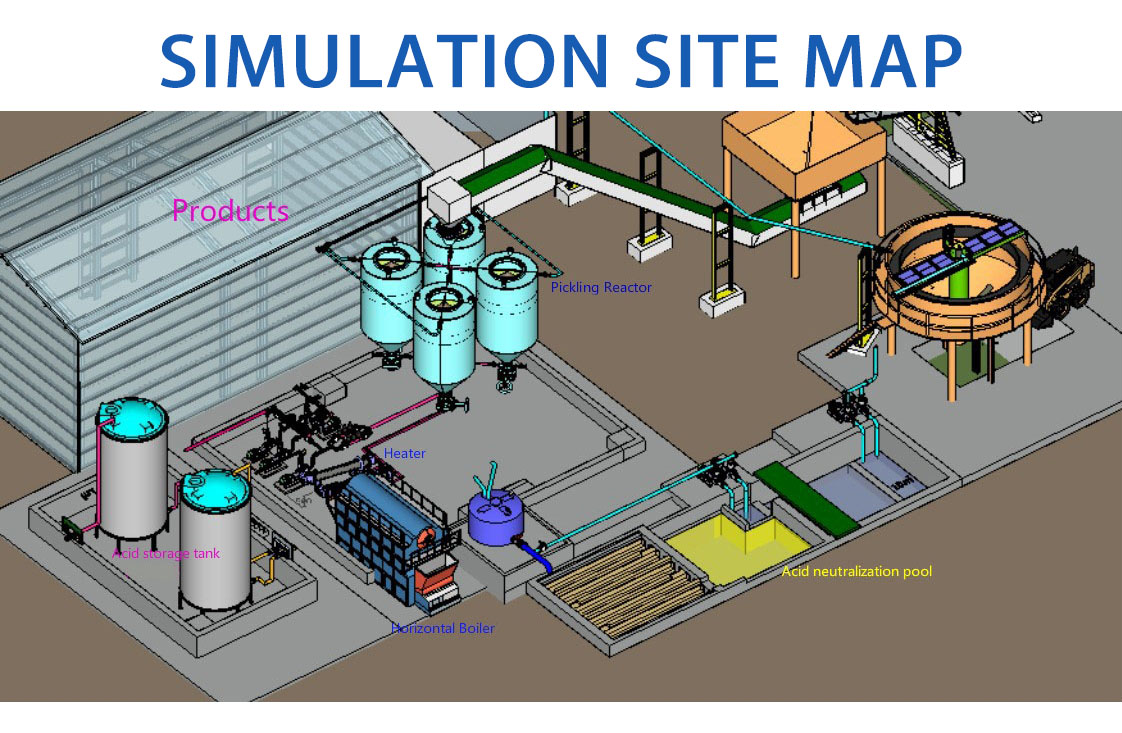

PROCESSING FLOW

Quartz pickling process is the core purification technology for producing high-purity quartz sand/silicon powder (especially electronic grade), which is mainly used to deeply remove non-magnetic metal impurities (mainly iron, aluminum, titanium, calcium, magnesium and other oxides) on the surface and cracks of quartz particles. Its essence is to use acid (mainly hydrochloric acid, sulfuric acid, oxalic acid or their mixture) to react chemically with impure metal oxides to generate soluble salts, which are then removed by repeated water washing, thereby significantly improving the purity of SiO2 (up to 99.99% or more).

This quartz sand/quartz stone purification acid washing process, through steps such as feeding, heating, acid washing to remove impurities, and unloading and rinsing, can obtain products with high purity and excellent appearance quality. The process fully realizes the recycling of acid, improving acid utilization efficiency. This process has a compact layout, low cost, and short reaction time, making it suitable for large-scale production.

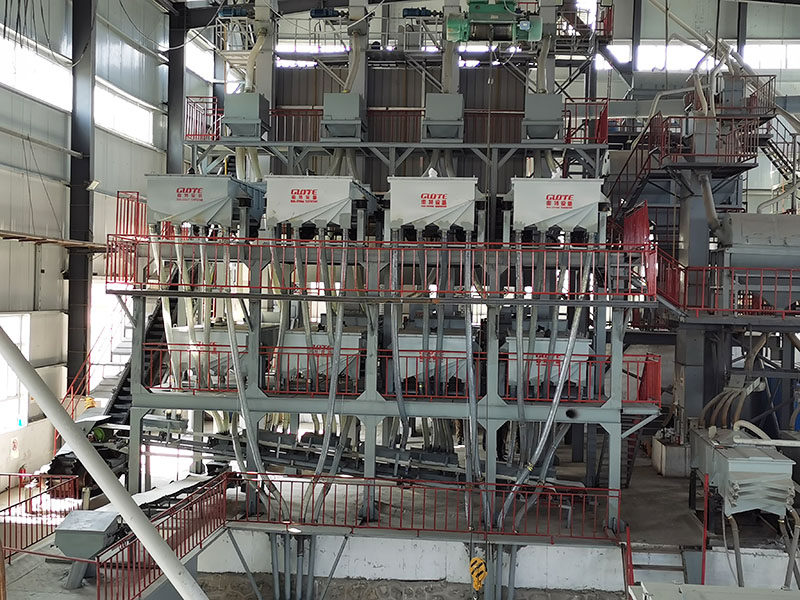

SUCCESSFUL CASE

RELATED PRODUCTS

RELATED NEWS

- 2024 Vietnam International Mining and Mineral Resources Recycling Exhibition

- Repair and maintenance of mining machinery and equipment.

- Process characteristics and process of quartz stone pickling

- Weifang Guote Mining Equipment Co., Ltd.

- What is a magnetic separator? What types of magnetic separators are there?

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE