The main structure and components of a quartz sand dryer are ingeniously designed, each with its own distinct functions, working together to achieve high-efficiency drying of quartz sand. The following is a detailed explanation of its main structure and components: First, the feeding system, as the initial stage of the quartz sand dryer, is responsible for smoothly and continuously conveying the material into the dryer. This system typically consists of a vibrating feeder, a belt conveyor, and other components to ensure even distribution of the quartz sand before entering the dryer, laying a solid foundation for the subsequent drying process.

First, the feeding system, as the initial stage of the quartz sand dryer, is responsible for smoothly and continuously conveying the material into the dryer. This system typically consists of a vibrating feeder, a belt conveyor, and other components to ensure even distribution of the quartz sand before entering the dryer, laying a solid foundation for the subsequent drying process. Second, the hot air system is the core of the quartz sand dryer. Consisting primarily of a heat source, a hot air blower, and air ducts, the hot air system provides a stable, high-energy heat source, enabling rapid moisture evaporation from the quartz sand during the drying process. A variety of heat sources are available, including electric heating, gas combustion, or biomass combustion, depending on specific needs and environmental standards.

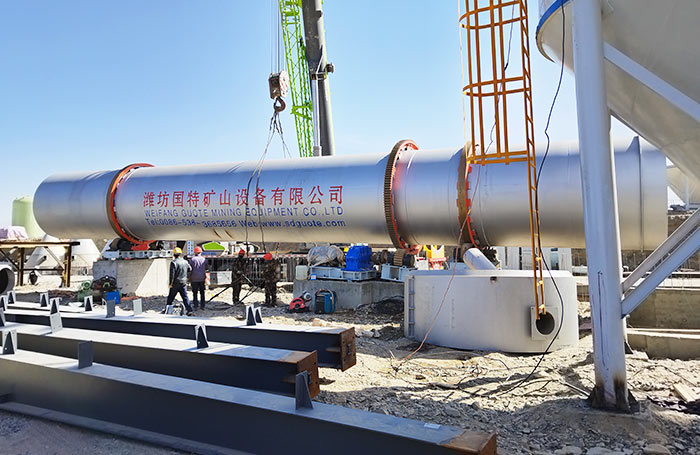

Second, the hot air system is the core of the quartz sand dryer. Consisting primarily of a heat source, a hot air blower, and air ducts, the hot air system provides a stable, high-energy heat source, enabling rapid moisture evaporation from the quartz sand during the drying process. A variety of heat sources are available, including electric heating, gas combustion, or biomass combustion, depending on specific needs and environmental standards. Third, the drying system is a key component of the quartz sand dryer. Its rationally designed internal structure ensures that the quartz sand is fully exposed to the hot air during the drying process, achieving high-efficiency drying. The drying system typically consists of a rotating drum and a dispersing device. The rotating drum continuously tumbles the quartz sand within, while the dispersing device ensures that the sand particles are fully dispersed to prevent clumping and blockage.

Third, the drying system is a key component of the quartz sand dryer. Its rationally designed internal structure ensures that the quartz sand is fully exposed to the hot air during the drying process, achieving high-efficiency drying. The drying system typically consists of a rotating drum and a dispersing device. The rotating drum continuously tumbles the quartz sand within, while the dispersing device ensures that the sand particles are fully dispersed to prevent clumping and blockage.

-

PRE

Repair and maintenance of mining machinery and equipment.

The daily maintenance of mining machinery can be roughly divided into three types: cleaning maintena…

-

NEX

Permanent Magnet Dry Roller Magnetic Separator

The high-field-strength roller magnetic separator, developed and manufactured by Weifang …

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE