Wet Drum Magnetic Separator

[Overview]:Wet drum magnetic separator is a kind of magnetic separation equipment with mature technology, wide application, high efficiency and reliability. It plays an irreplaceable role in the separation of strong magnetic minerals (especially magnetite), and also plays an important role in the fields of non-metallic mineral iron removal, medium recovery, environmental protection, etc. Its permanent magnetization design brings energy saving, stability, reliability and other advantages, making it one of the standard configurations of modern ore dressing plants.

[Scope of application]:Wet drum magnetic separator is suitable for the pre-selection, roughing and concentrating of materials such as magnetite, pyrrhotite, hematite, titanomagnetite, roasted ore, etc., as well as the early iron removal and purification of non-metallic minerals such as feldspar, quartz sand and kaolin.

ADVANTAGES

1. The magnetic system is reasonably designed, with a large magnetic penetration depth. The magnetic field strength of each sorting area is designed according to different functions. According to the different processes of the beneficiation plant and the properties of the ore, rollers with different magnetic field strengths can be selected, and the magnetic field strength can reach up to 1.0T.

2. The magnetic block is made of high-quality rare earth magnetic materials, which will not demagnetize after long-term use, and can ensure that the demagnetization is ≤3% in normal use for 8 years.

3. The magnetic block is fixed on the yoke by bolts + adhesive, which has double protection. The surface of the magnetic system is covered with a layer of stainless steel belt to ensure that the magnetic block will never fall off.

4. The through-axis chain/gear transmission structure design is adopted, and the force of each transmission part is reasonable, the transmission is stable, and the service life is long.

5. According to the different processes of the beneficiation plant and the properties of the ore, three different troughs can be selected: downstream, countercurrent, and semi-countercurrent. The trough adopts fluid dynamics design, and each sorting area is designed in a targeted manner, with good sorting effect.

(Key words:Wet drum magnetic separator,Drum magnetic separator,Wet drum permanent magnetic separator,Magnetic drum separator,Permanent magnet wet rotary drum magnetic separator.)

|

|

|

|

|

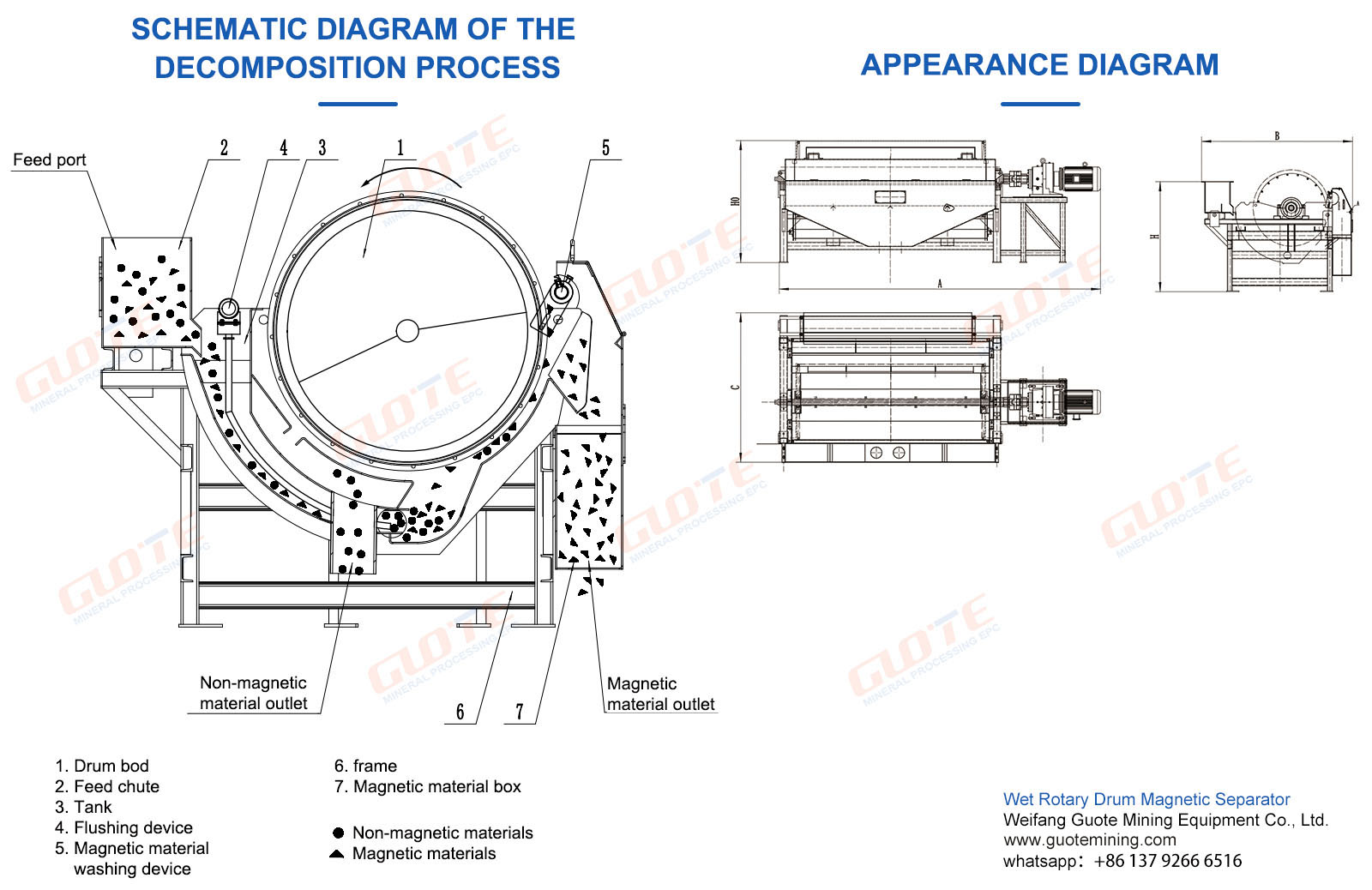

PRODUCT STRUCTURE

Introduction:Wet drum magnetic separator is suitable for mines, Coal preparation plant and other units. Used for weak magnetic field wet separation of fine paticles of strong magnetic minerals, or to remove mixed strong magnetic minerals from non magnetic minerals.The same cylinder of this machine can be equipped with three types of tanks: semi counter flow tank (CTB), counter flow tank(CTN), and forward flow tank (CTS), which are respectively suitable for diferent sorting particle sizes and diferent sorting process requirements. This product adopts computer optimized design, and the magnetic circuit is reasonable and strictly selects the permanent magnet with high Coercivity and high remanence, so as to ensure that the magnetism wil not decrease for a long time, protect the long-term interests of users, and the overall structure is reliable and durable.

Working principle:The slurry (a mixture of ore particles and water) is first fed into the sorting tank; at this time, the slowly rotating drum in the sorting tank (with a magnetic system fixed inside) adsorbs the magnetic mineral particles in the slurry to the drum surface, and is taken away from the slurry surface as the drum rotates; the non-magnetic (or weakly magnetic) particles are not affected by the magnetic force, and flow directly through the bottom or tail of the sorting tank into the non-magnetic ore bucket with the slurry flow; while the magnetic particles adsorbed on the drum surface are separated from the magnetic field area (usually reaching the top of the drum or the unloading area) by gravity and the flushing effect of flushing water, and fall into the magnetic ore bucket collection tank, finally realizing the separation of magnetic and non-magnetic ore.

TECHNICAL PARAMETERS

| Model | Cylinder size (mm) | Magnetic induction intensity of cylinder surface (MT) | Processing power | Motor power (kw) | Cylinder speed (r/min) | Total weight (kg) | ||||

| Average value | Sweep the selection area | Strong magnetic field in the midfield | Non-metallic minerals (t/h) | Metal materials(t/h) | m³/h | |||||

| CTB(N/S)-712 | 750*1200 | 160 | 200 | 200-300 | 5-10 | 10-20 | ≤60 | 3 | 35 | 1500 |

| CTB(N/S)-718 | 750*1800 | 160 | 200 | 300-500 | 5-15 | 20-45 | ≤72 | 3 | 35 | 2100 |

| CTB(N/S)-918 | 900*1800 | 170 | 200 | 300-600 | 12-22 | 25-40 | ≤90 | 5.5 | 28 | 2900 |

| CTB(N/S)-924 | 900*2400 | 170 | 200 | 300-600 | 12-22 | 40-50 | ≤90 | 5.5 | 28 | 3600 |

| CTB(N/S)-1018 | 1050*1800 | 180 | 220 | 300-700 | 20-35 | 45-60 | ≤120 | 7.5 | 22 | 4000 |

| CTB(N/S)-1021 | 1050*2100 | 180 | 220 | 300-700 | 22-44 | 50-70 | ≤140 | 7.5 | 22 | 4500 |

| CTB(N/S)-1024 | 1050*2400 | 180 | 220 | 300-700 | 26-60 | 60-80 | ≤170 | 7.5 | 22 | 5000 |

| CTB(N/S)-1030 | 1050*3000 | 180 | 220 | 300-700 | 40-70 | 80-120 | ≤200 | 11 | 22 | 6300 |

| CTB(N/S)-1218 | 1200*1800 | 180 | 220 | 300-800 | 30-40 | 60-75 | ≤150 | 11 | 19 | 4900 |

| CTB(N/S)-1224 | 1200*2400 | 180 | 220 | 300-800 | 40-55 | 80-110 | ≤200 | 11 | 19 | 5900 |

| CTB(N/S)-1230 | 1200*3000 | 180 | 220 | 300-800 | 50-80 | 100-140 | ≤270 | 11 | 19 | 7200 |

| CTB(N/S)-1245 | 1200*4500 | 180 | 220 | 300-800 | 80-110 | 150-200 | ≤660 | 18.5 | 17 | 9500 |

| CTB(N/S)-1530 | 1500*3000 | 180 | 220 | 300-800 | 55-100 | 100-180 | ≤320 | 18.5 | 14 | 9900 |

| CTB(N/S)-1540 | 1500*4000 | 180 | 220 | 300-800 | 60-120 | 115-220 | ≤400 | 22 | 14 | 11000 |

| CTB(N/S)-1545 | 1500*4500 | 180 | 220 | 300-800 | 100-130 | 180-240 | ≤650 | 22 | 14 | 12500 |

| CTB(N/S)-1840 | 1800*4000 | 180 | 220 | 300-800 | 110-140 | 200-260 | ≤650 | 30 | 11 | 20000 |

| CTB(N/S)-1850 | 1800*5000 | 180 | 220 | 300-800 | 150-170 | 280-320 | ≤800 | 37 | 11 | 23000 |

RELATED PRODUCTS

RELATED NEWS

- Weifang Guote Mining Equipment Co., Ltd.

- Repair and maintenance of mining machinery and equipment.

- 2024 Guote Mining Equipment Promotional Film

- Process characteristics and process of quartz stone pickling

- What is a magnetic separator? What types of magnetic separators are there?

- 2024 Vietnam International Mining and Mineral Resources Recycling Exhibition

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE