Water Bath Dust Collector

[Overview]:The water bath dust collector is a wet dust removal device that uses water or other liquids to fully contact dust-laden gases, capturing dust particles using droplets, liquid films, or liquid nets while simultaneously absorbing harmful gases. Its core mechanisms include physical interactions such as inertial collision, gravitational settling, and water mist adhesion, achieving three-phase separation of gas, liquid, and solid. Suitable for high-humidity and high-dust conditions, it combines dust removal and desulfurization, achieving an overall efficiency exceeding 95%.

[Application Scenarios]:Widely used in industrial environments with high humidity, high dust, and corrosive gases, such as those found in mining and stone processing; coal-fired boilers, foundries, and kilns; and sticky/irritating dust in the chemical, paint, and pharmaceutical industries. By adding alkaline substances (such as lime) to the circulating water, it simultaneously removes sulfides, achieving desulfurization efficiencies exceeding 80%.

ADVANTAGES

1. Highly Efficient Purification: Dust removal efficiencies exceeding 95%-98%, effectively reducing smoke emission concentrations.

2. Economical and Durable: Compact structure with no moving parts (extractor and blower), resulting in low maintenance costs. The interior is lined with granite or ceramic for corrosion and high temperature resistance, ensuring a long service life.

3. Safe and Environmentally Friendly: Water is recycled, and sludge can be used to make bricks or cement raw materials. The explosion risk is minimized, making it suitable for combustible dust.

4. Highly Adaptable: Compatible with high-humidity and highly sticky dust.

|

|

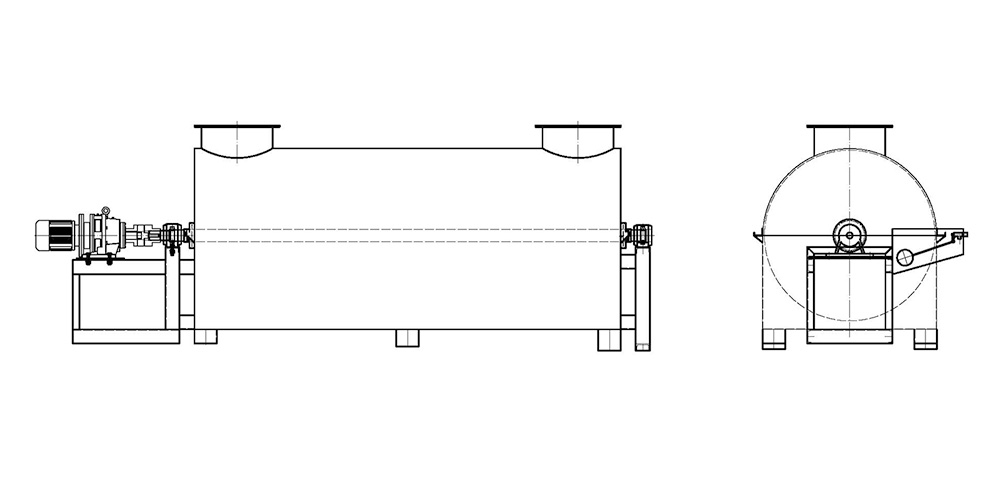

PRODUCT STRUCTURE

Introduction:The water bath dust collector is a wet dust removal technology. Its typical structure includes an air inlet, a water trough, an S-shaped deflector (or nozzle), a mist eliminator, and a fan. Dust-laden air is introduced into the water trough via a pipe. High-speed impact with the water surface, turbulent mixing, and water mist spraying capture dust. The purified air is then dehydrated and discharged. The equipment does not require complex nozzles or pumps; it relies on self-excitation of the airflow to form a water curtain, making it easy to operate.

Working principle:1. Impact Phase: Dust-laden air impacts the water surface at high speed, causing large dust particles to fall into the water due to inertia. 2. Water Bath Stage: The airflow stirs up water droplets and foam, creating a turbulent zone where fine dust particles are attracted by the water film. The high-temperature flue gas generates steam, enhancing capture capacity. 3. Atomization Stage: The gas turns upward and comes into contact with the top spray mist for a second time, further purifying it. 4. Dehydration and Emission: The gas is dehydrated by the demister and discharged by the fan. The settled sludge is regularly cleaned, and the gray water is recycled.

TECHNICAL PARAMETERS

| Model | GLY1540 | GLY1230 |

| Dimensions (mm) | 5430*1800*2310 | 4330*1500*1940 |

| Screen Mesh Size | 10 mesh | 10 mesh |

| Motor Power (kw) | 4 | 3 |

| Shaft Speed (r/min) | 24 | 24 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE