Vertical Sand Making Machine

[Overview]:The vertical sand making machine (also known as a vertical shaft impact sand making machine or a composite sand making machine) is a highly efficient sand making machine designed specifically for crushing medium-sized ores. It utilizes the centrifugal impact principle ("stone on stone" or "stone on iron"), with a high-speed rotating impeller or hammer repeatedly impacting and rubbing the material, achieving both fine and coarse crushing. It offers a high crushing ratio, adjustable output particle size, and a high tolerance for moisture content. It also features a screen-free design for anti-clogging and a self-lining for wear resistance.

[Application Scenarios]:It is widely used in the mining, construction, and environmental protection sectors, such as crushing quartz, river pebbles, granite, and basalt. It is used in quartz sand purification production lines, construction sand, and road aggregate. It is also used in construction waste recycling, tailings treatment, and sulfur removal projects, such as steel slag crushing.

ADVANTAGES

1. High Efficiency and Energy Saving: The crushing rate is 30% higher than traditional equipment, and the finished sand yield is over 90%. The particles are cubic and contain low levels of needle-like flakes.

2. Durable and Low-Consumption: The screen-free design prevents clogging, the impeller is self-lined to reduce wear, and the wearing parts are made of alloy. The inner wall is lined with silica, corundum, and other materials, extending the service life several times and reducing maintenance costs by 40%.

3. Environmentally Friendly: Noise level is less than 75 decibels, with low dust pollution. It supports high-water-content materials and wet processing reduces dust.

4. Flexible Control: The output particle size can be precisely controlled by adjusting the speed or increasing or decreasing the number of hammers via a frequency converter.

5. Air Separation System: Equipped with an adjustable air separation system, the fine powder generated during the sand making process is instantly sucked out according to the mesh size, minimizing excessive material loss and dust generation.

|

|

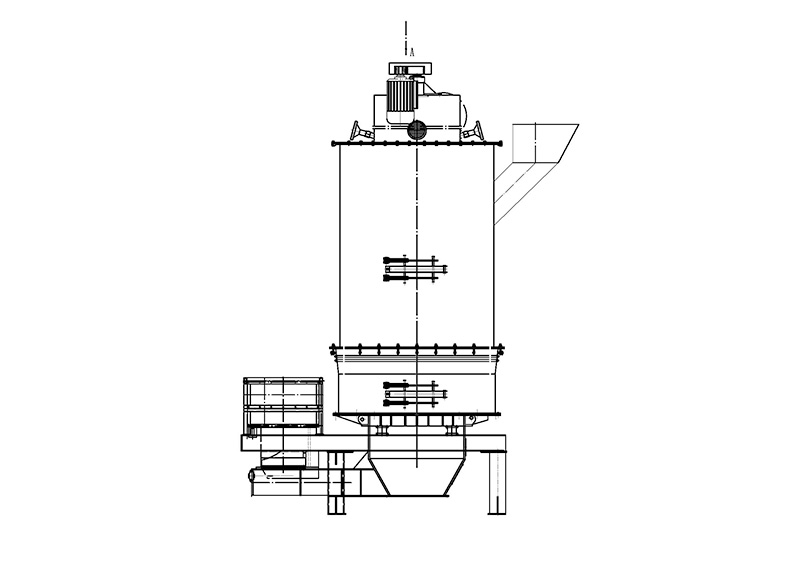

PRODUCT STRUCTURE

Introduction:The vertical sand making machine consists of a transmission, main shaft, cylinder, and impeller (or hammer rotor). Material falls vertically from the top feed port into the high-speed rotating impeller. Centrifugal force exerts a powerful impact on the surrounding material, causing it to rub and pulverize repeatedly in the vortex chamber before finally being discharged from the bottom.

Working principle:The sand making machine requires 2-3 cm thick raw materials to be fed directly from the top of the machine onto the high-speed rotating disc. Driven by the motor, the rotor rotates at high speed, causing the material entering from the feed port to collide with the surrounding material. Under the influence of high-speed centrifugal force, the material, which is diverted around the disc in an umbrella-shaped pattern, undergoes high-speed collisions and high-density crushing. After the material impacts each other, it forms a vortex motion between the disc and the casing, causing repeated collisions, friction, and pulverization before finally being discharged from the discharge port.

TECHNICAL PARAMETERS

| Model | Feed size (mm) | Product particle size (mesh) | Host power (kw) | Dust removal area (m³) | Rotation speed (r/h) | Processing capacity (t/h) |

| GZP180 | ≤25 | 4-120 | 83 | 100 | Frequency adjustable | 10-15 |

| GZP200 | ≤25 | 4-120 | 118 | 150 | 13-20 | |

| GZP220 | ≤30 | 4-120 | 161 | 200 | 15-25 | |

| GZP260 | ≤35 | 4-120 | 235 | 300 | 25-35 |

RELATED PRODUCTS

RELATED NEWS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE