Vertical Air Classifier

[Overview]:The air classifier is a device that uses centrifugal force and airflow to dry-size powder materials. Its core principle is to use a high-speed rotating classifying rotor to generate a centrifugal field, separating powders entering the classification chamber by size in a gas-solid two-phase flow. Coarse particles sink due to centrifugal force and gravity, while fine particles flow through the gaps between the classifying blades and into a collection system. During this process, secondary air washes the coarse powder, redispersing agglomerated fine powders and achieving secondary classification, ultimately producing a highly precisely graded finished product.

[Scope of application]:This device is widely applicable for fine grading of powders across a wide range of industries, including non-metallic minerals (quartz, kaolin, calcium carbonate), metal powders (aluminum powder, magnesium powder), and new materials (magnetic materials, phosphors). It is particularly well-suited for applications requiring iron-free and narrow particle size distribution, such as ceramic glazes and pharmaceutical ultrafine powders.

ADVANTAGES

1. High Efficiency and Energy Saving: The low-speed vertical impeller classifier structure ensures a stable material flow field, large processing capacity, and high classification efficiency.

2. High Precision: The vertical impeller, combined with sealing technology, eliminates coarse particle leakage, resulting in high classification accuracy, concentrated particle size, and a wide classification range.

3. High Flexibility: Supports multi-stage cascade production of products in multiple particle size ranges, or can be combined with a ball mill to form a closed-circuit system.

4. Intelligent and Environmentally Friendly: Variable frequency speed regulation, PLC automatic control, and negative pressure operation with dust emissions ≤ 15 mg/m³.

5. Material Adaptability: The internal use of wear-resistant materials such as ceramic reduces equipment wear and ensures a pollution-free, high-purity product.

|

|

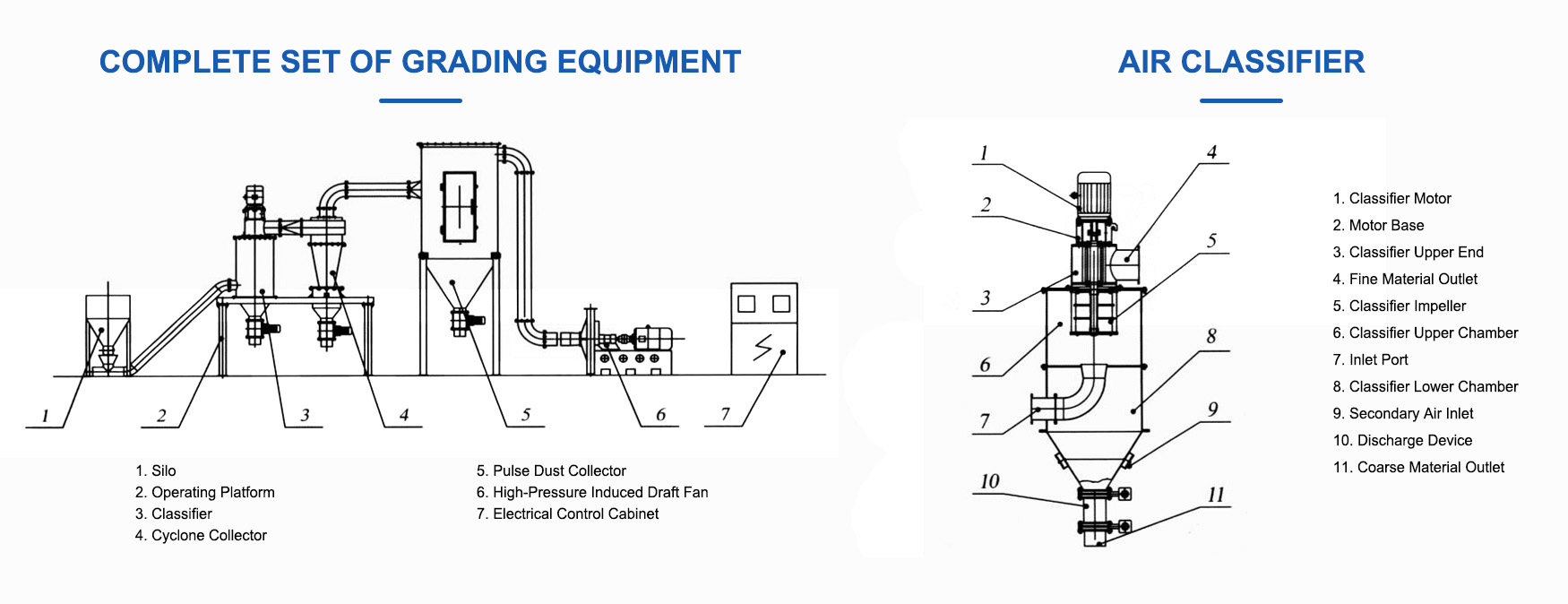

PRODUCT STRUCTURE

Introduction: The air classifier system consists of a feed control system, a classifier main unit, a cyclone collector, a pulse dust collector, and an induced draft fan. Its core innovation lies in forced vortex classification technology, which precisely controls the cut particle size by adjusting the impeller speed and air volume.

Working principle:The air classifier is a forced classifier with secondary air inlet and a vertically mounted large impeller. During operation, materials enter the lower barrel under the influence of the induced draft fan's gravity and rise to the partitions. Due to the high-speed rotation of the classifying impeller rotor, the particles are subjected to both the centrifugal force generated by the rotation of the classifying impeller and the centripetal force generated by the induced draft fan. When the centrifugal force on the particles is greater than the centripetal force, the coarse particles above the classification diameter are thrown to the inner wall of the barrel, stall and slide down the wall. The external secondary air enters through the air inlets evenly distributed on the cone, creating a wind sieve effect on the coarse particles, and cleanly separates the fine powder mixed with or adhering to the coarse material. The separated coarse material is collected and discharged from the classifier by the discharge device, while the fine powder below the classification diameter is collected by the air flow into the cyclone collector and pulse dust collector. The purified gas is discharged by the induced draft fan.

TECHNICAL PARAMETERS

| Specifications | Processing capacity (feeding amount) (kg) | Classification efficiency (%) | Product particle size (um) | Matching power (kw) |

| GF010 | 10—50 | 70—90 | D97=5—50 | 7 |

| GF020 | 50—350 | 70—90 | D97=5—50 | 15—19 |

| GF050 | 100—800 | 70—90 | D97=5—50 | 25—30 |

| GF100 | 300—1500 | 70—90 | D97=5—50 | 41—48 |

| GF200 | 500—4000 | 70—90 | D97=5—50 | 63—73 |

| GF400 | 2000—5000 | 70—90 | D97=5—50 | 97—120 |

| GF500 | 3000—6000 | 70—90 | D97=5—50 | 110—130 |

| GF600 | 4000—8000 | 70—90 | D97=5—50 | 110—169 |

| GF800 | 6000—12000 | 70—90 | D97=5—50 | 170—210 |

| GF1200 | 8000—20000 | 70—90 | D97=5—50 | 230—380 |

SUCCESSFUL CASE

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE