Three Cylinder Dryer

[Overview]:The three cylinder dryer is a highly efficient and energy-saving drying device consisting of three coaxial, horizontally nested inner, middle, and outer drums. The rotating drums drive a lifting plate to repeatedly distribute the material, ensuring full contact with the hot airflow for dehydration. Its core design lies in its multi-stage heat exchange and self-insulating structure. The high-temperature airflow in the inner drum directly heats the material, while the middle and outer drums utilize residual heat for indirect drying, minimizing heat loss.

[Application Scenarios]:Suitable for granular or powdered materials with an initial moisture content of ≤50%, such as: 1. Drying iron powder, metal concentrate, tailings, and leach residue to improve sorting efficiency; 2. Processing cement raw materials, quartz sand, river sand, etc.; 3. Drying non-heat-sensitive materials such as bentonite, petroleum coke, and molding sand; 4. Drying coal slime, lignite, and sewage sludge to achieve resource utilization.

ADVANTAGES

1. Highly efficient and energy-efficient: Compatible with coal, oil, and gas. Thermal efficiency reaches 80% (compared to 35% for a single-drum dryer), coal consumption is reduced by 30–70%, and electricity consumption is reduced by 60%;

2. Compact and space-saving: At only 30–35% of the length of a single-drum dryer, it reduces floor space by 50% and construction costs by 50%;

3. Highly adaptable: It can handle lump materials ≤20mm, granular materials, and powders, and has a temperature resistance of 750°C (heat-resistant steel plate material supports high-temperature requirements);

4. Durable and environmentally friendly: Customizable 304, 316 stainless steel, or alloy steel plate materials offer four times greater wear resistance, exhaust temperatures below 100°C, and dust recovery rates exceeding 95% when combined with a dust removal system;

5. Intelligent control: PLC-controlled moisture content enables automated operation, reducing manual intervention.

|

|

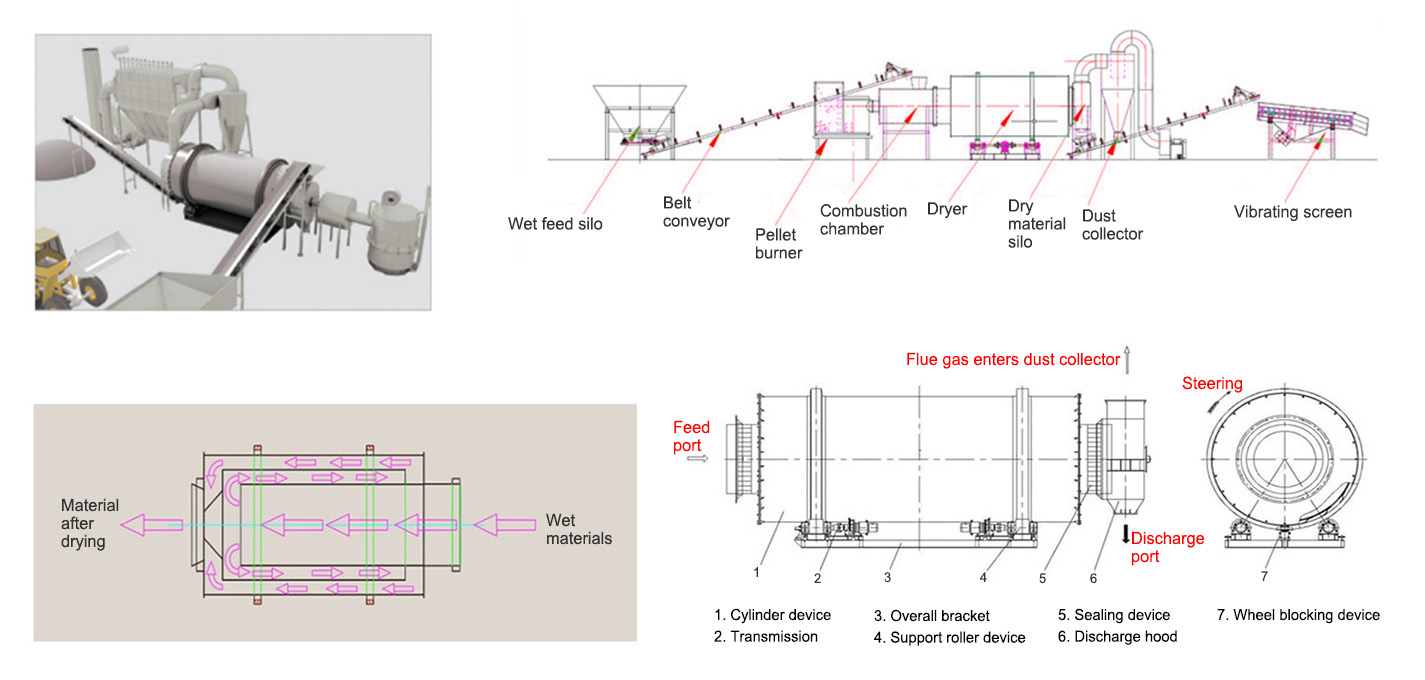

PRODUCT STRUCTURE

Introduction:Three cylinder dryer, with its core principle of “multi-stage heat exchange + self-insulation,” utilises three drum layers to synergistically halve energy consumption and double thermal efficiency. Its compact structure and high adaptability make it a key piece of equipment for improving resource utilization in the building materials, mining, and environmental protection sectors. The three-drum dryer consists of nested cylinders (inner, middle, and outer), a drive system (friction-driven by rollers), a hot air furnace (coal/gas/oil), and a dust removal unit. Curved spiral lifters and guide plates are installed within the drums, allowing the material to move in an S-shaped path through the three drums.

Working principle:1. Feeding and Initial Drying: Wet material enters the inner drum from the feed end, where it is dispersed by the spiral guide plates and then scattered by the lifters. Direct contact with the downstream hot air evaporates the moisture. 2. Countercurrent Heat Exchange in the Middle Drum: The material falls into the middle drum and moves in the opposite direction, absorbing the heat emitted by the inner drum and the hot air flow from the middle drum, extending the drying time and improving uniformity. 3. Insulated Dehydration in the Outer Drum: The material enters the outer drum and moves leftward, indirectly drying it using low-temperature waste heat. The drum itself insulates the material to minimize heat loss. 4. Discharge and Dust Removal: After drying, the material is discharged from the outer drum outlet. The exhaust gas is removed through a cyclone and bag filter, achieving a dust recovery rate of over 95%.

TECHNICAL PARAMETERS

| Model Specifications | GHS-2245 | GHS-2506 | GHS-2807 | GHS-3007 | GHS-3208 | GHS-3608 |

| Outer cylinder diameter (m) | 2.2 | 2.5 | 2.8 | 3 | 3.2 | 3.6 |

| Outer tube length (m) | 4.5 | 6 | 7 | 7 | 8 | 8 |

| Cylinder speed (rpm) | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 |

| Motor power (kw) | 5.5×2 | 5.5×4 | 7.5×4 | 11×4 | 37 | 45 |

| Machine weight (t) | 6 | 7.4 | 15.3 | 32 | 43 | 48 |

| Initial moisture content of quartz sand (%) | 6-12 | 6-12 | 6-12 | 6-12 | 6-12 | 6-12 |

| Final moisture content of quartz sand (%) | 1 | 1 | 1 | 1 | 1 | 1 |

| Maximum intake air temperature (°C) | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ |

| Production capacity (t/h) | Quartz sand 10-15 | Quartz sand 20-25 | Quartz sand 30-35 | Quartz sand 35-45 | Quartz sand 50-60 | Quartz sand 60-75 |

RELATED PRODUCTS

RELATED NEWS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE