The MDC Pulse Bag Filter

[Overview]:The pulse bag filter is a highly efficient industrial dust removal device that uses pulsed compressed air to remove dust from the filter bag surface, achieving gas-solid separation. Its core design utilizes a chambered, air-stop cleaning mechanism. After pre-separation in the ash hopper, the dust-laden gas is intercepted by the filter bags, and the purified gas is discharged into the atmosphere. The cleaning process is precisely controlled by a PLC or pulse controller, ensuring dust removal efficiencies exceeding 99.9%.

[Application Scenarios]:Widely used in high-dust industries such as mining, construction, cement, metallurgy, pharmaceuticals, food, electricity, and plastics. For example, dust is collected during the drying of concentrates such as iron ore and quartz ore; blast furnace gas and sintering machine exhaust dust are purified; and boiler flue gas treatment meets ultra-low emission standards.

ADVANTAGES

1. Optimal combination: Utilizing co-current inlet and filtration, the filter achieves both agglomeration and settling of dust during filtration, reducing filter bag load and pulse frequency.

2. Lean Workmanship: The smooth exterior surface eliminates weld wear, eliminating wear between the filter bag and frame and extending the filter bag's service life. The filter bag openings are sealed with elastic expansion rings for excellent airtightness and easy assembly and disassembly. The frame is resistance welded.

3. High-Efficiency Dust Removal: Separate chamber airflow-stop cleaning technology thoroughly removes dust with an efficiency of 99.9% and a PM2.5 removal rate of >95%.

4. Energy Saving and Consumption Reduction: The low-pressure pulse design (0.4–0.7 MPa) saves 30% more energy than high-pressure pulse cleaning, with a system resistance of <1500 Pa.

5. Intelligent Control: The PLC dynamically adjusts the cleaning frequency, achieving a pressure differential fluctuation of <0.1% and supporting unmanned operation.

|

|

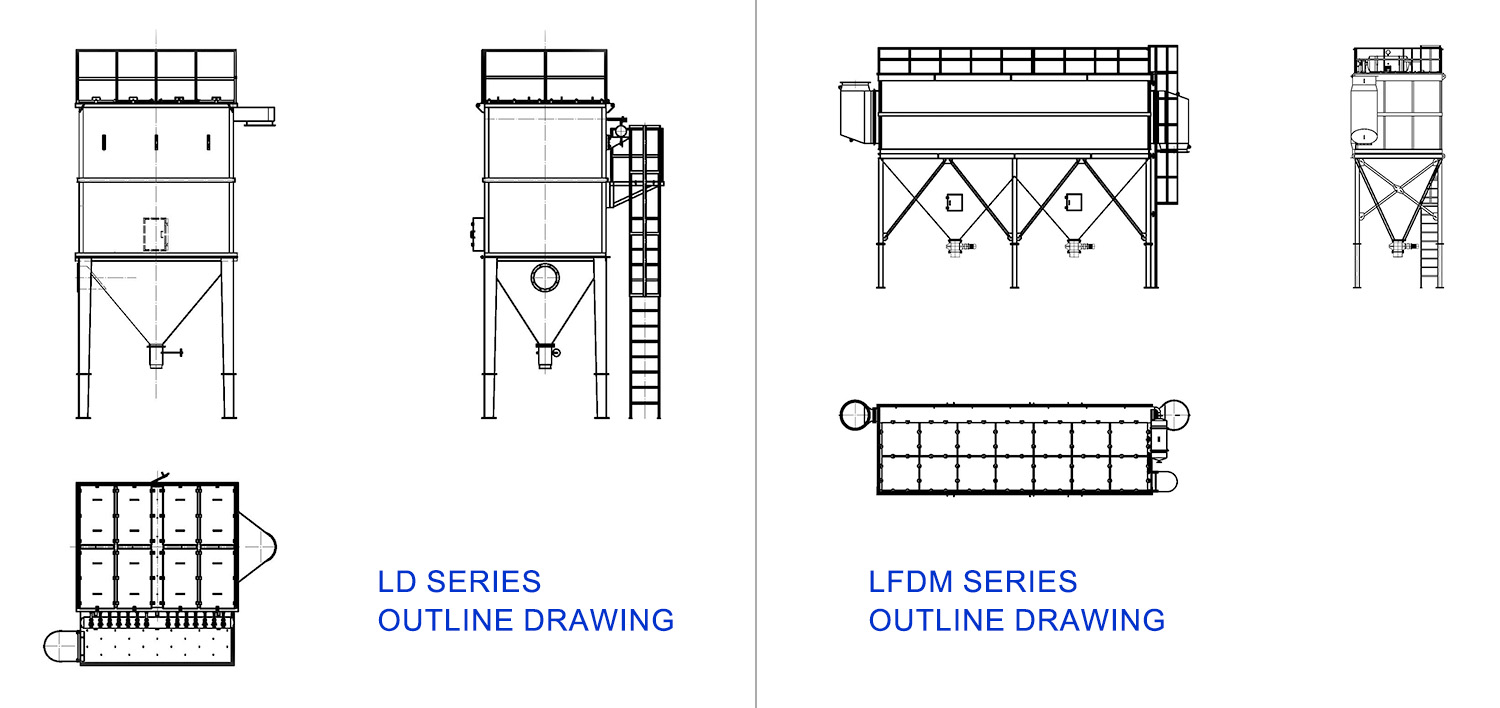

PRODUCT STRUCTURE

Introduction:The pulse bag dust collector, with its core technology of “separate chamber airflow-stop + pulsed injection,” achieves near-zero emissions through intelligent control and innovative materials. Its modular design adapts to high-dust, high-temperature, and high-corrosion environments across multiple industries, making it a key piece of equipment for cost reduction, efficiency improvement, and environmental compliance in the green industrial transformation. The equipment consists of a hopper (coarse particle settling area), a middle housing (filter bag filtration area), an upper housing (clean air chamber), and a pulse jet system. The filter bag material can be selected according to the operating conditions.

Working principle:Dust-laden air enters the middle and lower housings from the dust collector's air inlet. It is filtered through the filter bags, separating dust and air. Dust is adsorbed on the filter bag surfaces, and clean air passes through the bags and is discharged through the air outlet. Over time, as dust accumulates on the filter bag surfaces, the pulse jet valves are triggered and opened sequentially according to the pulse jet instrument's program. Compressed air in the air bag is instantly ejected from each hole in the jet pipe, through a venturi, and into the corresponding filter bag. Dust adsorbed on the filter bag surfaces is then dislodged and falls into the hopper, where it is discharged through the ash discharge valve or directly into the hopper.

TECHNICAL PARAMETERS

| Model | LD-120 | LD-160 | LD-200 | LD-300 | LFDM96-5 | LFDM96-6 | LFDM96-7 | LFDM96-8 | LFDM96-10 |

| Filter Area (m²) | 120 | 160 | 200 | 300 | 480 | 576 | 672 | 768 | 1200 |

| Number of Filter Bags (pcs) | 120 | 160 | 200 | 288 | 480 | 576 | 672 | 768 | 960 |

| Filter Bag Specifications (mm) | Φ133×2500 | ||||||||

| Operating Temperature (°C) | <120 | ||||||||

| Equipment Resistance (Pa) | 1000-1500 | ||||||||

| Dust Removal Efficiency (%) | >99 | ||||||||

| Inlet Dust Concentration (mg/m³) | <15 | ||||||||

| Filter Air Velocity (m/min) | 1-1.2 | ||||||||

| Air Volume (m³/h) | 6000-9600 | 8000-12800 | 10000-16000 | 15000-24000 | 24000-38400 | 28800-46080 | 33600-53760 | 38400-61440 | 60000-96000 |

| Injection Air Pressure (Pa) | 0.5-0.7 | ||||||||

| Pulse Width (s) | 0.1-0.2 | ||||||||

| Pulse Interval (s) | 1-5 | ||||||||

RELATED PRODUCTS

RELATED NEWS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE