Square Swing Screen

[Overview]:The square swing screen is a high-efficiency screening equipment that achieves material grading and screening through a three-dimensional composite motion trajectory (horizontal circular motion superimposed on vertical throwing motion). Its design combines the principles of bionics, and uses eccentric blocks and flexible connecting rods to drive the material in a spiral diffusion trajectory on the screen surface, significantly improving the screening efficiency. The equipment is based on a modular structure and supports 1-5 layers of screen configuration. The fully enclosed body takes into account environmental protection and low noise characteristics, and is widely used in high-precision screening scenarios.

[Application scenarios]:Demonstrating strong adaptability across multiple industries: 1. Mining/Chemicals: Screening of quartz sand (accuracy ±0.5μm), processing heavy alkali, resin, and other viscous materials; 2. Food/Pharmaceuticals: Fine screening of flour, milk powder, and salt; 3. New Energy Materials: Screening efficiency of lithium battery anode materials reaches 98.5%. It can also process feed and metallurgical powders.

ADVANTAGES

1. Complete range: single-layer and multi-layer can be selected at will, and the discharge port can be rotated 360° at will, which is suitable for continuous assembly line production.

2. Special elastic ball: Use special bouncing ball, which has better elasticity than other manufacturers on the market, can greatly reduce the blockage of the sieve holes and better promote screening.

3. Unique grid: The wave-shaped steel plate bending method is adopted to increase the probability of the bouncing ball colliding with the screen, which can achieve better screening effect.

4. Special screen: The wear-resistant screen made of stainless steel or polyurethane is adopted to increase the life of the screen, greatly reduce the frequency of replacing the screen and the cost of use.

5. Accurate positioning: It can effectively screen particles, powders, and slurry materials, especially suitable for quartz sand particles.

6. Environmental adaptability: Fully enclosed structure to prevent dust from spilling.

|

|

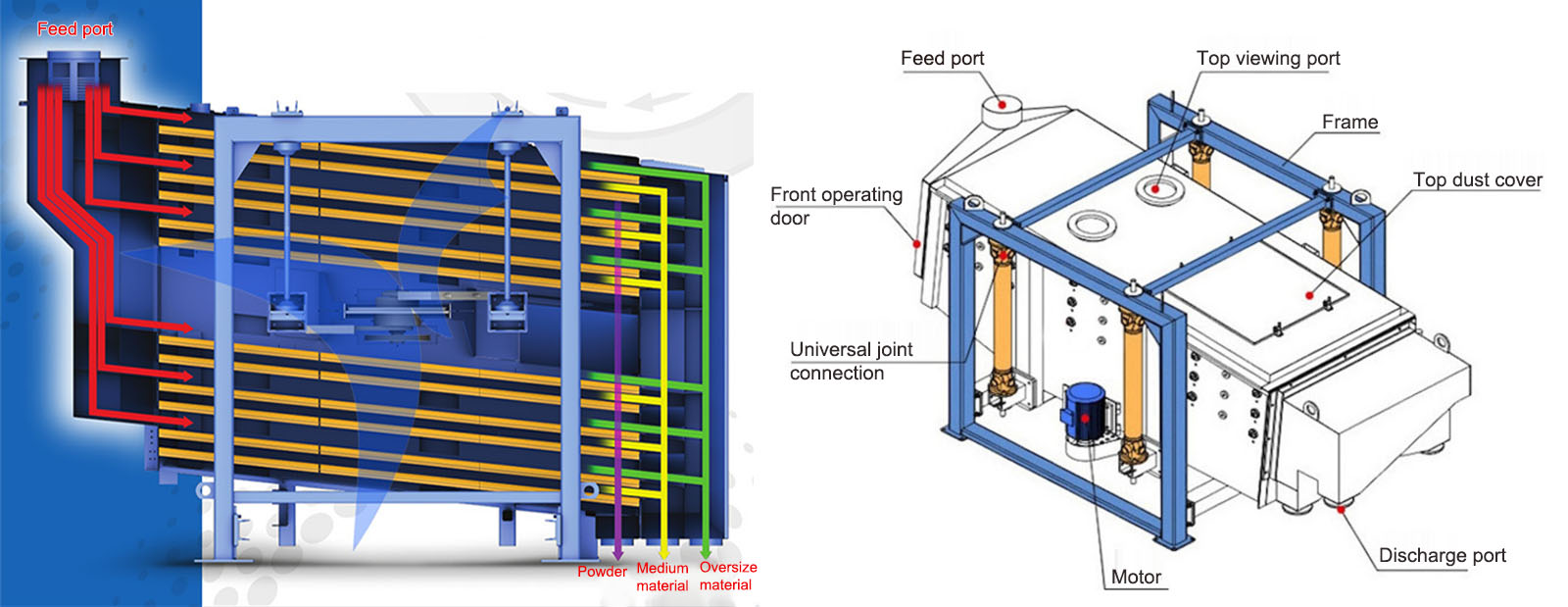

PRODUCT STRUCTURE

Introduction: The square swing screen can also be called a reciprocating vibrating screen or a precision vibrating screen. The vibrator generates vibration and swinging motion, which is transmitted to the screen surface, so that the material is quickly dispersed in front of the screen machine, thereby achieving efficient screening. The main structure includes a screen box, an exciter, a dual motor drive system, a rubber spring shock-absorbing module and a self-cleaning device.

Working principle: The vibration force generated by the square swing screen motor drive device is an inertial force that rotates around the fixed axis and changes in a certain regularity. It is essentially a reciprocating inertial force formed by the rotation of the eccentric wheel around the fixed axis. According to its structural characteristics and working principle, its screen surface is generally arranged horizontally or slightly inclined (the inclination angle is 0-5°). After the square swing screen is started, the screen box reciprocates back and forth under the action of inertial force, and the screen box and the screen surface are shaken periodically, so that the material on the screen surface moves in a directional jumping manner with the screen box. During this period, particles smaller than the screen hole fall through the screen hole to the lower layer and become screen undersize, and particles larger than the screen hole are discharged from the discharge port after continuous tumbling and jumping movements, thereby completing the screening work.

TECHNICAL PARAMETERS

| Model | Effective screening area (㎡) | Power (kw) | Screen surface inclination (°) | Number of layers | Rotation frequency (r/min) | Screen box stroke (mm) | Dimensions (mm) |

| GFYB1030 | 3 | 3 | 5—8 | 1—5 | 180—260 | 25—60 | 3842*1700*1917 |

| GFYB1036 | 3.6 | 3 | 4442*1700*1917 | ||||

| GFYB1230 | 3.6 | 4 | 3842*1900*1917 | ||||

| GFYB1236 | 4.32 | 4 | 4442*1900*1917 | ||||

| GFYB1530 | 4.5 | 5.5 | 3842*2200*1917 | ||||

| GFYB1536 | 5.4 | 5.5 | 4442*2200*1917 | ||||

| GFYB1830 | 5.4 | 7.5 | 3842*2500*1917 | ||||

| GFYB1836 | 6.48 | 7.5 | 4442*2500*1917 | ||||

| GFYB2030 | 6 | 7.5 | 3842*2700*1917 | ||||

| GFYB2036 | 7.2 | 7.5 | 4442*2700*1917 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE