Sand Single Drum Dryer

[Overview]:The single-drum dryer for mining is a horizontal rotary drum drying device. The drum's rotation drives an internal lifting plate to repeatedly distribute the material, allowing it to fully engage with the hot air flow and achieve dehydration. The main body consists of a single drum, mounted at an angle (typically 3–5 degrees), supported by rollers at both ends for rotation. The feed end is connected to a hot air furnace (fueled by coal, gas, or oil), and the discharge end is equipped with a dust removal system.

[Application Scenarios]:This core design focuses on optimizing thermal efficiency and material compatibility. It is widely used in industries such as mineral processing, building materials, metallurgy, and chemicals. Applications include: 1. Drying metal concentrates and tailings to improve subsequent sorting efficiency; 2. Processing blast furnace slag, cement raw materials, quartz sand, river sand, etc.; 3. Drying non-heat-sensitive materials such as bentonite and petroleum coke; 4. Drying coal slime, lignite, and biomass pellets for fuel production or tailings resource utilization.

ADVANTAGES

1. High-quality materials: The drum is welded from all 304 stainless steel or alloy steel plates, increasing wear resistance by 3–4 times. The modular design simplifies ongoing maintenance.

2. Compact design: An internal lifting device ensures even material dispersion, facilitates moisture evaporation, and maintains heat on the outside.

3. Energy-saving and environmentally friendly: A multi-combination lifting plate eliminates the “wind tunnel” effect. The heat source uses biomass or natural gas, resulting in high thermal efficiency and zero pollution.

4. Comprehensive supporting facilities: The entire production line is equipped with a high-temperature, environmentally friendly dust collector, ensuring dust and pollutant-free production.

5. High adaptability: It can handle 20–40mm lumps, pellets, and powders, and is heat-resistant up to 800°C (made of special heat-resistant steel plates).

|

|

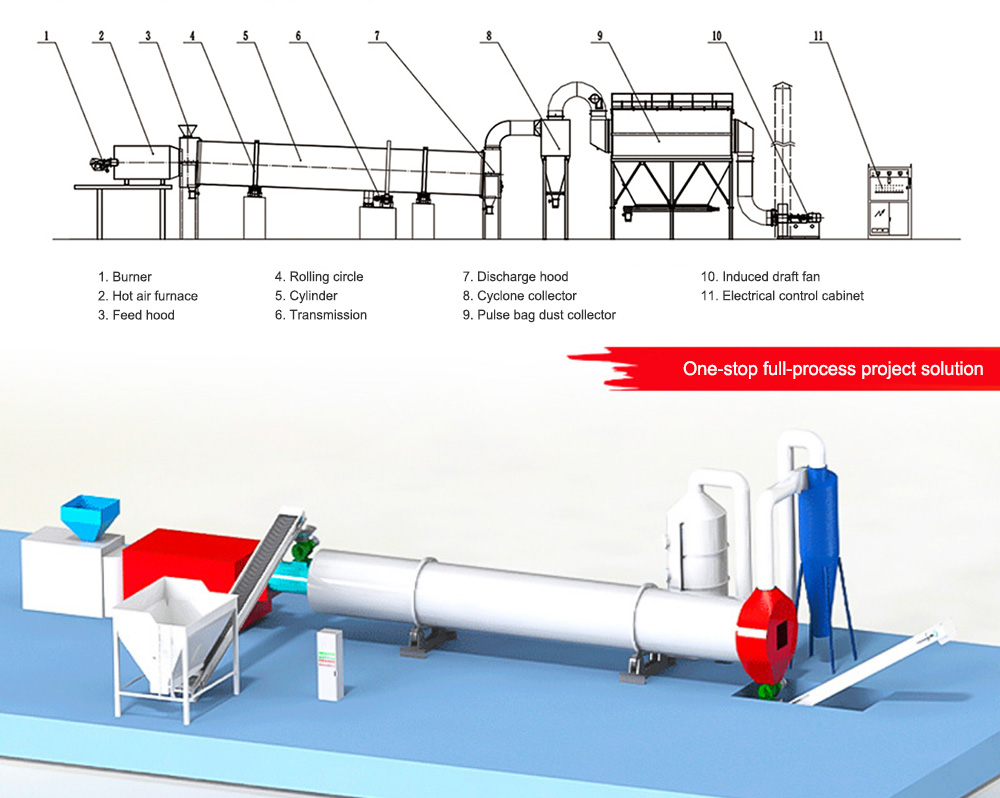

PRODUCT STRUCTURE

Introduction:Mining single-drum dryer utilizes a “mechanical spreading + hot air convection” mechanism. It achieves highly energy-efficient dehydration through innovative lifting plates and optimized process flow (co-current/counter-current). Its wide compatibility (including slag, chemical materials, and biomass) and significant energy efficiency (thermal efficiency exceeding 80%) make it a key piece of equipment for improving resource utilization and reducing carbon emissions in the mining and building materials industries. A single-drum mining dryer consists of a drum, a lifting plate, a drive system (motor + reducer + roller), a support device, sealing rings, a hot air furnace, and a dust removal unit.

Working principle:Wet material is delivered to the hopper by a belt conveyor or bucket elevator. It then enters the hopper's feeder through a feeding pipe and into the feed end. The feeding pipe's slope should be greater than the material's natural inclination to ensure smooth material flow into the dryer. The dryer drum is a rotating drum slightly inclined to the horizontal. Material is fed at the higher end, while the heat carrier enters at the lower end, interacting with the material in countercurrent flow. Sometimes, the heat carrier and material flow together into the drum. Lifting plates are installed on the inner wall of the drum to lift and drop the material, increasing the contact surface between the material and the airflow, thereby increasing the drying rate and promoting material forward movement. The dried material falls onto the conveyor belt through the discharge port and is driven into the finished product warehouse.

TECHNICAL PARAMETERS

| Specification | GHG-1310 | GHG-1512 | GHG-1816 | GHG-2016 | GHG-2218 | GHG-2418 | GHG-2822 |

| Outer cylinder diameter (m) | 1.3 | 1.5 | 1.8 | 2.0 | 2.2 | 2.4 | 2.8 |

| Outer tube length (m) | 10 | 12 | 16 | 16 | 18 | 18 | 22 |

| Cylinder speed (rpm) | 2—6 | 2—6 | 2—6 | 2—6 | 2—6 | 2—6 | 2—6 |

| Initial moisture content of materials (%) | 6—12 | 6—12 | 6—12 | 6—12 | 6—12 | 6—12 | 6—12 |

| Moisture content of materials (%) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Maximum intake air temperature (°C) | 750—900°C | 750—900°C | 750—900°C | 750—900°C | 750—900°C | 750—900°C | 750—900°C |

| Production capacity (t/h) | 6—10 | 10—13 | 15—20 | 20—25 | 25—30 | 30—35 | 40—50 |

| Motor power (kw) | 16 | 18.5 | 22 | 30 | 37 | 45 | 75 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE