Slurry Scrubbing Machine

[Overview]:The slurry scrubber is a mechanical device specifically designed for processing high-concentration slurries. It uses mechanical agitation and hydraulic pressure to remove mud, impurity films, and cement from the ore surface. Its core function is to provide pretreatment conditions for mineral processing, and it is suitable for separating mud and sand from minerals such as quartz sand, feldspar, and tin ore.

[Application Scenarios]:1. Mining: Used for scrubbing mud and sand from minerals such as quartz sand and potassium-sodium feldspar, removing surface clay and impurity films to improve subsequent mineral processing purity. 2. Building Materials and Infrastructure: Used in production lines for river pebble sand and basalt crushing and sand production, as well as for aggregate cleaning in concrete mixing plants and highway construction. 3. Specialty Mineral Processing: Desludging phosphate and iron ore, particularly suitable for high-mud and sticky ores that are difficult to clean.

ADVANTAGES

1. High Efficiency and Energy Saving: The impeller is positioned above the slurry settling zone, requiring low starting power and providing high agitation intensity, resulting in a 30% increase in scrubbing efficiency compared to traditional equipment.

2. Wear-Resistant and Durable: The trough and impeller are constructed of highly wear-resistant materials (such as polyurethane and national standard steel plates) to extend service life.

3. Flexible Adaptability: The dual-trough model allows for customized feed/discharge positions to accommodate various production line layouts.

4. Easy Maintenance: The compact structure and minimal wearing parts reduce operating and maintenance costs.

|

|

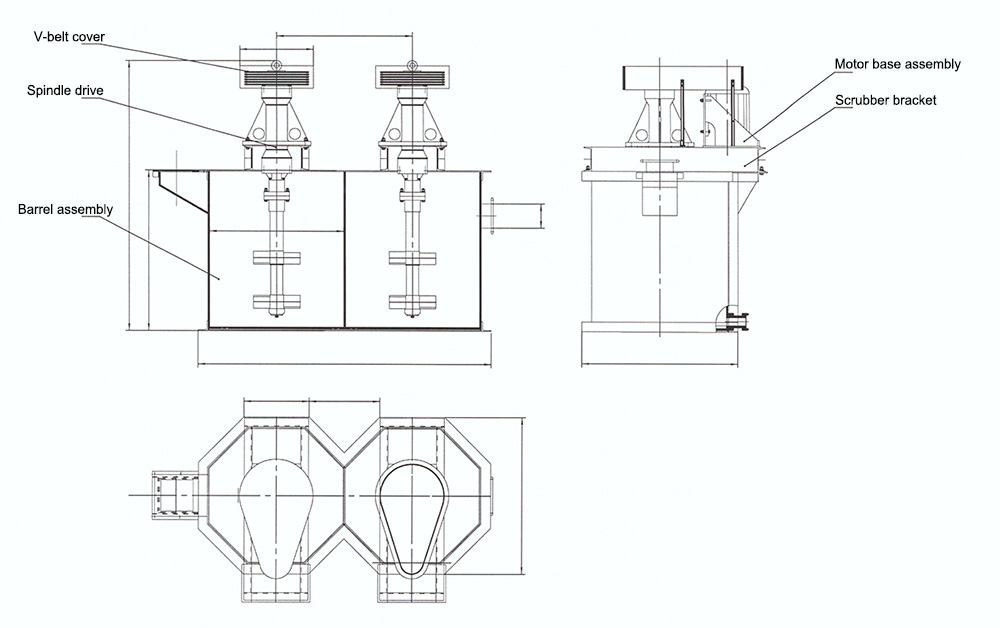

PRODUCT STRUCTURE

Introduction: The slurry scrubber consists of a motor, main shaft, impeller, wear-resistant trough, and transmission system. This equipment is often integrated with a sand washer, dewatering screen, and cyclone to achieve an integrated “scrubbing-cleaning-dewatering” system.

Working principle:The slurry enters the scrubber cavity through the feed pipe. Under the powerful stirring action of the impeller, the slurry produces violent turbulence. The mineral particles have huge kinetic energy and produce violent friction and collision with each other. The impurity film wrapped on the surface of the mineral particles is not strong, so it is easily peeled off the mineral surface after friction and collision. The cement on the surface of the mineral will loosen and break after being soaked in water and then the strong friction and collision between the mineral particles, so as to achieve the separation of clay and mineral particles. These film impurities and clay break and peel off into the slurry, and the slurry can be separated after subsequent desludging. In the actual production process, different reagents should be added according to the actual situation of the mineral.

TECHNICAL PARAMETERS

| Model | Volume (m³) | Feed size (mm) | Slurry concentration (%) | Electric power (kw) | Dimensions (mm) | Reference weight (kg) |

| GSC1-1 | 1 | ≤5 | 50—60 | 11 | 1420*1310*1860 | 1300 |

| GSC1-2 | 2 | ≤5 | 50—60 | 11X2 | 2340*1310*1860 | 2500 |

| GSC2-1 | 2 | ≤5 | 50—60 | 30 | 2150*1900*2780 | 3200 |

| GSC2-2 | 4 | ≤5 | 50—60 | 30X2 | 3530*1900*2780 | 5300 |

| GSC4-1 | 4 | ≤5 | 50—60 | 55 | 2596*2800*3441 | 3800 |

| GSC4-2 | 8 | ≤5 | 50—60 | 55X2 | 4430*2800*3441 | 7500 |

| GSC6-2 | 12 | ≤5 | 50—60 | 90X2 | 4900*3200*4100 | 9500 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE