Rotary Drum Screen

[Overview]:The drum screen is a non-vibrating large-scale screening equipment. The core component is a cylindrical screen drum installed at an angle (usually 3°–6°), which is rotated by a motor-driven reducer. It adopts the principle of rolling conveying and is suitable for screening materials with high humidity, high viscosity and impurities. It is characterized by simple structure, large processing capacity (up to 200m³/h), and universal use of dry and wet materials.

[Application scenarios:]:It is widely used in industries that need to classify solid materials by particle size. Mining/coal: raw coal classification, mineral (iron ore, quartz sand) screening, suitable for complex materials such as inferior coal and coal slime; building materials and sand making: sand and gravel aggregate classification, construction waste sorting (separation of concrete, bricks and stones);chemical and metallurgy: catalyst particle classification, slag recovery, suitable for fine powdered raw materials such as gypsum powder and activated carbon; environmental protection field: urban domestic waste sorting, compost residue treatment.

ADVANTAGES

1. Strong anti-clogging performance: The material tumbling motion combined with the comb-type cleaning mechanism effectively prevents clogging of the screen holes (especially for highly viscous materials);

2. Energy-saving and environmentally friendly: The power consumption is only 1/2–1/3 of that of a vibrating screen, and the noise level is below 60dB. The fully enclosed structure suppresses dust escape;

3. Easy maintenance: The modular and split screen design allows for easy replacement; the through-shaft structure operates smoothly and has few wearing parts;

4. Adaptability and flexibility: Customizable fully enclosed or open structures, various screen combinations (2–120mm mesh), and flexible feeding methods (belt, hopper, etc.);

5. Compact design: A buffer drum is provided to reduce impact when the material enters the screen surface;

6. Advanced improvements: A layer of PVC wear-resistant sleeve is added to the transverse round steel of the screen drum, and the screen mesh is made of stainless steel.

|

|

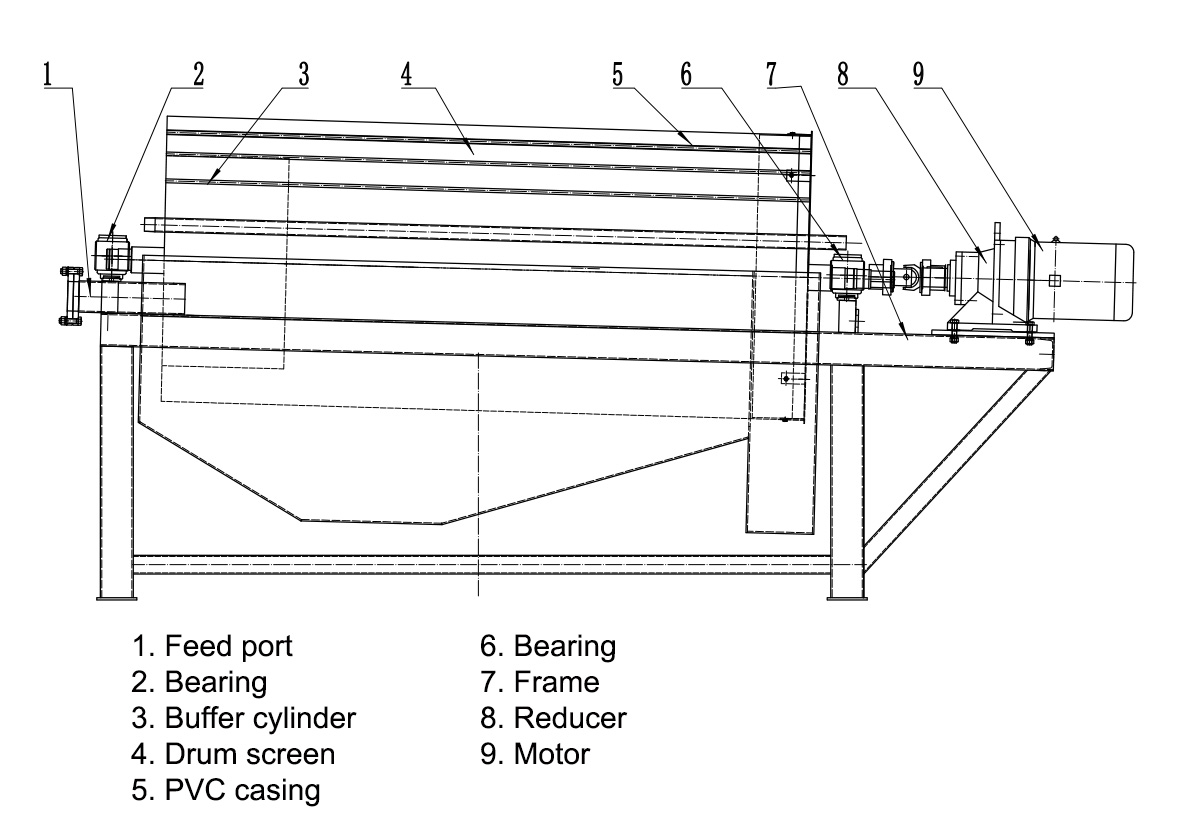

PRODUCT STRUCTURE

Introduction: Drum screens, with their strong adaptability, low clogging rate, and energy efficiency, have become key equipment for solid material classification, particularly suitable for challenging environments such as mining, coal mining, and construction waste. The drum screen is designed to solve the problem of wet and sticky material screening blockage. The main body includes a screen drum, a drive system (motor + reducer), a frame and a sealing cover. The screen drum is composed of wear-resistant flat steel rings or special screens. The segmented design can achieve multi-level screening (such as fine → coarse 4-level screens).

Working principle: After the particles enter the drum device, they first fall into the buffer drum. Due to the inclination and rotation of the drum device, the materials on the buffer drum are scattered on the drum screen. After flipping and rolling, and moving to the discharge end due to gravity, the particles smaller than the screen hole (screen under) pass through the screen hole and fall into the collection hopper, and the particles larger than the screen hole (screen over) are discharged through the coarse material outlet at the end of the drum. Due to the flipping and rolling of the material in the drum, the material stuck in the screen hole can be ejected to prevent the screen hole from being blocked. The comb-type cleaning mechanism is used to clean the screen surface in real time to ensure continuous and efficient screening.

TECHNICAL PARAMETERS

| Model | Cylinder size (m) | Cylinder inclination | Cylinder speed (rpm) | Sieve hole size (mm) | Maximum feed particle size (mm) | Output (m³/h) | Motor power (kw) | |

| Sieve hole 2mm | Sieve hole 20mm | |||||||

| GTS-820 | Φ0.8X2 | 6° | 32 | 2-20 | Mesh size X2.5 | 7 | 30 | 3 |

| GTS-830 | Φ0.8X3 | 6° | 32 | 2-20 | Mesh size X2.5 | 8 | 50 | 3 |

| GTS-1030 | Φ1X3 | 6° | 25 | 2-20 | Mesh size X2.5 | 10 | 60 | 4 |

| GTS-1040 | Φ1X4 | 6° | 25 | 2-20 | Mesh size X2.5 | 11 | 80 | 4 |

| GTS-1230 | Φ1.2X3 | 6° | 20 | 2-20 | Mesh size X2.5 | 12 | 100 | 5.5 |

| GTS-1240 | Φ1.2X4 | 6° | 20 | 2-20 | Mesh size X2.5 | 14 | 120 | 5.5 |

| GTS-1250 | Φ1.2X5 | 6° | 20 | 2-20 | Mesh size X2.5 | 15 | 150 | 5.5 |

| GTS-1530 | Φ1.5X3 | 6° | 17 | 2-20 | Mesh size X2.5 | 16 | 120 | 5.5 |

| GTS-1540 | Φ1.5X4 | 6° | 17 | 2-20 | Mesh size X2.5 | 18 | 150 | 7.5 |

| GTS-1550 | Φ1.5X5 | 6° | 17 | 2-20 | Mesh size X2.5 | 20 | 180 | 11 |

| GTS-1560 | Φ1.5X6 |

6° | 17 | 2-20 | Mesh size X2.5 | 22 | 200 | 11 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE