RCYD Self-cleaning Permanent Magnet Iron Separator

[Overview]:RCYD self-unloading permanent magnetic iron separator is an automatic iron removal equipment based on high-performance NdFeB permanent magnetic core, which consists of a magnetic source system, a discarded iron belt, a reduction motor, a waist drum and a frame. Its core feature is the automatic iron unloading function, which can continuously remove 0.1-50 kg of ferromagnetic impurities (such as bolts and broken iron blocks) without manual intervention, and is suitable for scenes with high iron content. The equipment operates without power supply, the eight-year attenuation rate of the magnetic field is ≤3%, the service life is over 15 years, and the operating temperature covers -25℃ to 50℃.

[Application scenarios]:Widely used in cement, thermal power generation, metallurgy, mining, chemical industry, coal and other industries, especially suitable for continuous operation in harsh environments such as dust, humidity, and salt spray corrosion.

ADVANTAGES

Iron separator,Permanent magnet separator,RCYD iron separactor,RCYD self-cleaning permanent magnet iron separator,Permanent magnetic separator,Permanent magnet self-discharging iron separator,Self-discharging iron separator,Self-unloading iron separator,Belt iron separator.

1. Reasonable structure, fully sealed bearing seat.

Waist drum-shaped roller structure, with automatic deviation correction function, fully sealed bearing seat, good sealing performance.

2. Reliable operation in harsh environment.

High-performance NdFeB as magnetic source, extremely high magnetic energy, not easy to demagnetize, demagnetization does not exceed 3% in eight years.

3. Analog design, high magnetic field strength.

Using computer simulation design, double pole structure, high magnetic field strength, large gradient, and strong suction.

4. Intelligent control, simple and convenient operation.

The control part can be interlocked with the belt conveyor to realize two modes of on-site manual control and centralized control.

5. Absorb impurities and have good iron unloading effect.

Automatic belt unloading can ensure long-term trouble-free continuous operation.

|

|

|

|

|

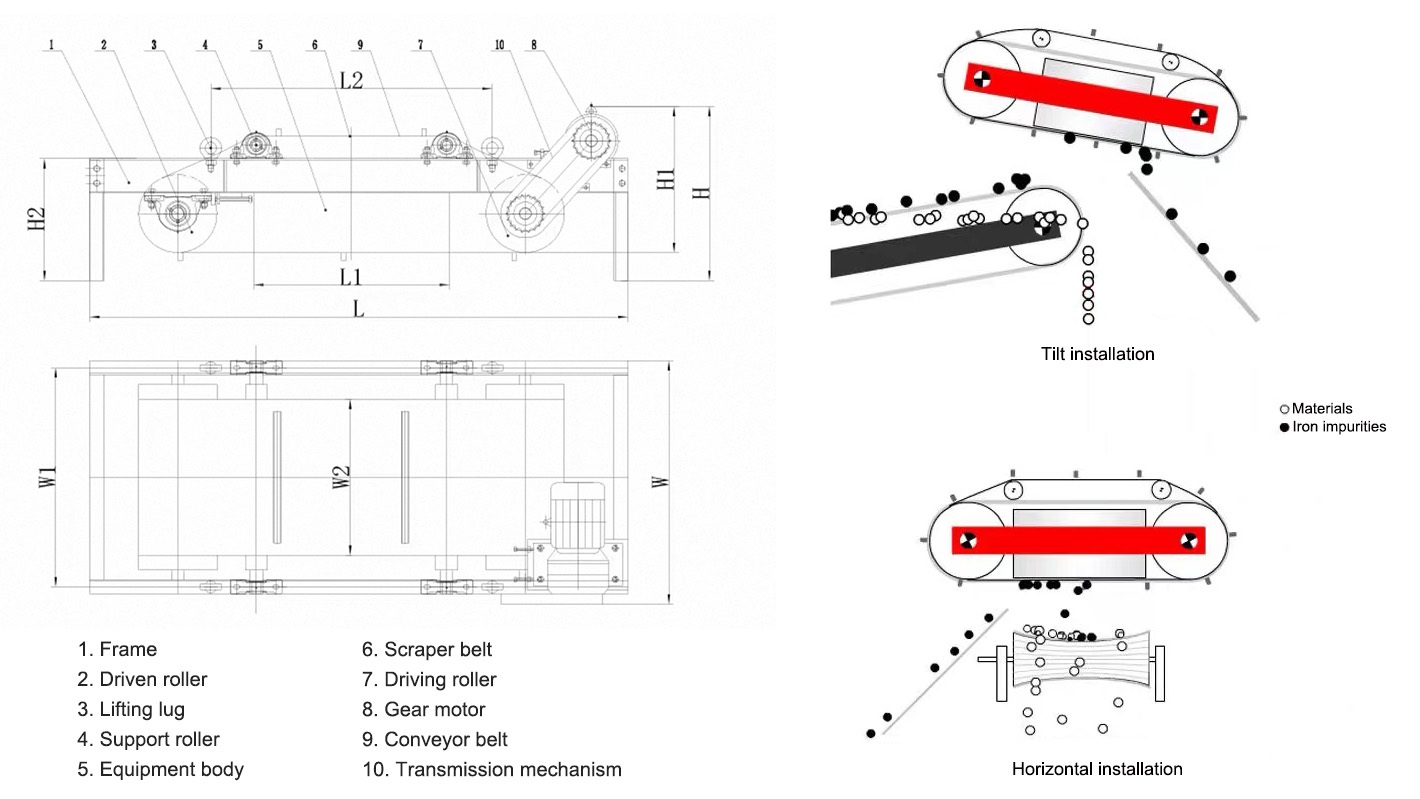

PRODUCT STRUCTURE

Introduction: The main body of RCYD permanent magnet separator consists of three parts: permanent magnet system, unloading mechanism, and explosion-proof motor. The magnetic system is designed by computer simulation, with a perfect double-pole structure, magnetic field strength ≥65-75mT (such as RCYD-10 up to 70mT), and the whole machine can operate for a long time without trouble in harsh environment. The unloading belt adopts stainless steel scraper, and the throwing distance is ≥500mm; the drum waist drum structure prevents deviation. Customized models are available (such as explosion-proof motor models), suitable for bandwidths of 500–2000mm (such as RCYD-16 is suitable for 1600mm bandwidth), maximum material processing thickness of 500mm, and belt speed ≤4.5m/s.

Working principle: When the material passes under the iron remover, the ferromagnetic impurities are adsorbed to the belt surface by the strong magnetic field generated by the NdFeB magnet; the reduction motor drives the belt to run, and the iron filings are transported to the non-magnetic area (magnetic force disappears area), and the scraper automatically throws them into the iron collection box. There is no need to stop the whole process, realizing the “iron absorption-iron delivery-iron abandonment” closed loop, which is especially suitable for continuous production in high iron content scenarios.

TECHNICAL PARAMETERS

| Model | Beit Width(mm) | Hanging Height(h≤mm) | Magnetic Strengh(≥mT) | Material Thickness (≤mm) | Driving Power(≤KW) | Belt speed(≤m/s) | Weight(KG) | Overall Dimension(mm) |

| RCYD-5 | 500 | 150 | 60 | 80 | 1.5 | 4.5 | 750 | 1900*735*935*950*753 |

| RCYD-6 | 600 | 175 | 60 | 120 | 1.5 | 4.5 | 920 | 2050*780*1030*1100*753 |

| RCYD-6.5 | 650 | 200 | 70 | 150 | 2.2 | 4.5 | 1200 | 2165*780*1080*1200*888 |

| RCYD-8 | 800 | 250 | 70 | 200 | 2.2 | 4.5 | 1400 | 2350*796*1280*1300*1088 |

| RCYD-10 | 1000 | 300 | 70 | 250 | 3.0 | 4.5 | 2120 | 2660*920*1550*1400*1335 |

| RCYD-12 | 1200 | 350 | 70 | 300 | 4.0 | 4.5 | 3350 | 2860*1010*1720*1550*1515 |

| RCYD-14 | 1400 | 400 | 70 | 350 | 4.0 | 4.5 | 4450 | 3225*1050*1980*1800*1755 |

| RCYD-16 | 1600 | 450 | 70 | 400 | 5.5 | 4.5 | 6200 | 3350*1180*2160*1950*1850 |

| RCYD-18 | 1800 | 500 | 72 | 450 | 5.5 | 4.5 | 8100 | 3580*1210*2450*2200*2130 |

| RCYD-20 | 2000 | 550 | 72 | 500 | 7.5 | 4.5 | 9700 | 3800*1300*2700*2400*2410 |

RELATED PRODUCTS

RELATED NEWS

- Weifang Guote Mining Equipment Co., Ltd.

- Repair and maintenance of mining machinery and equipment.

- 2024 Guote Mining Equipment Promotional Film

- Process characteristics and process of quartz stone pickling

- What is a magnetic separator? What types of magnetic separators are there?

- 2024 Vietnam International Mining and Mineral Resources Recycling Exhibition

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE