RCYB Suspension Permanent Magnet Iron Separactor

[Overview]:RCYB Suspension permanent magnet iron separactor is an industrial iron removal equipment based on NdFeB permanent magnet material to build a composite magnetic system. It uses high coercivity inside and is designed for removing ferromagnetic impurities (such as iron blocks, bolts, etc.) from non-magnetic materials. Its core features are maintenance-free operation (no electricity or cooling system required) and long life (magnetic system life ≥ 10 years), which can remove 0.1 to 35 kg of iron impurities.

[Application scenarios]:Suspension iron separactor is widely used in mining, coal, cement, chemical, food and pharmaceutical industries. For example: in the mining industry, iron removal is performed before the crusher to protect the equipment from damage; in the cement industry, iron removal is performed before the raw materials enter the mill to ensure the quality of grinding.

ADVANTAGES

Suspension Permanent Magnet Iron Separactor,RCYB magnetic separator,RCYB Iron Separactor,Suspension Iron Separactor.

1. Energy saving and environmental protection: no excitation coil, zero power consumption, and reduced carbon emissions;

2. High reliability: no risk of circuit failure, constant magnetic field without “hot and cold” difference;

3. Low maintenance cost: no cooling system is required, resistant to harsh environment (dustproof, anti-corrosion), and extremely low failure rate;

4. Strong and lasting magnetism: the magnetic force of the NdFeB magnetic source decays ≤3% within ten years, and the suction force is stable.

|

|

|

|

|

PRODUCT STRUCTURE

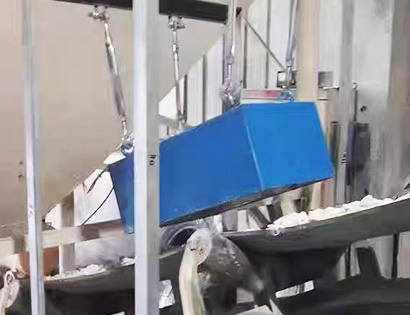

Introduction:RCYB Suspension iron separactor consists of a permanent magnetic system, a wear-resistant stainless steel shell, and an adjustable suspension bracket. The magnetic system is optimized by computer simulation, and the magnetic field is deep and evenly distributed. The shell is corrosion-resistant and adapts to high temperature and high dust environments. Flexible installation, customizable surface color, and customizable suspension height according to bandwidth, adaptable to a variety of scenarios such as belt conveyors, vibrating conveyors, and electromagnetic vibrating feeders, with an operating temperature range of -25℃~+50℃.

Working principle:When the material passes under the iron remover, the ferromagnetic impurities are adsorbed to the surface of the magnet by the strong magnetic field generated by the NdFeB, and the non-magnetic material continues to be transported. The cleaning method is manual intervention: regularly use a non-magnetic scraper or wear gloves to remove adsorbed iron impurities (suitable for scenarios with low iron content).

TECHNICAL PARAMETERS

| Model | Belt width(mm) | Hanging Height(h≤mm) | Belt speed(≤m/s) | Material Thickness(≤mm) | Weight(kg) | Overall Dimension(mm) |

| RCYB-4 | 400 | 125 | 4.5 | 60 | 115 | 400*300*230 |

| RCYB-4-1 | 400 | 75 | 4.5 | 30 | 65 | 400*250*140 |

| RCYB-5 | 500 | 150 | 4.5 | 90 | 206 | 500*350*260 |

| RCYB-5-1 | 500 | 100 | 4.5 | 50 | 96 | 500*260*160 |

| RCYB-6 | 600 | 175 | 4.5 | 120 | 295 | 600*450*280 |

| RCYB-6-1 | 600 | 130 | 4.5 | 60 | 158 | 600*350*180 |

| RCYB-6.5 | 650 | 200 | 4.5 | 150 | 450 | 650*600*300 |

| RCYB-8 | 800 | 250 | 4.5 | 200 | 680 | 950*950*380 |

| RCYB-8-1 | 800 | 200 | 4.5 | 150 | 550 | 800*600*300 |

| RCYB-10 | 1000 | 300 | 4.5 | 250 | 1180 | 1100*1000*380 |

| RCYB-12 | 1200 | 350 | 4.5 | 300 | 1670 | 1300*1340*420 |

| RCYB-14 | 1400 | 400 | 4.5 | 350 | 2350 | 1500*1500*420 |

| RCYB-16 | 1600 | 450 | 4.5 | 400 | 2850 | 1750*1750*460 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE