RCDF Forced Oil Circulation Cooling Iron Separator

[Overview]:RCDF oil-water cooled electromagnetic iron remover is a high-efficiency magnetic separation equipment designed for removing ferromagnetic impurities from non-metallic materials (such as coal and ore). It adopts a composite cooling technology of forced oil circulation and water cooling system, and solves the problem of magnetic field attenuation of traditional iron removers in harsh environments such as high temperature and dust through a closed cooling structure.

[Application scenarios]:Mainly suitable for industrial sites with high dust, high humidity and corrosive environments. For example: large thermal power plants and coal transportation ports, coal mines and mines, building materials and chemical industries. It is especially suitable for large-scale conveying systems with a bandwidth of ≤2400mm and a belt speed of ≤5.8m/s to meet the needs of high-precision iron removal.

ADVANTAGES

1. Efficient and stable heat dissipation: The oil-water composite cooling system (oil internal circulation + water cooling heat exchange) achieves a temperature rise of ≤40℃, which is much lower than ordinary air cooling (temperature rise ≤70℃), and the magnetic field strength attenuation is almost zero;

2. Strong environmental adaptability: The coil is fully sealed and immersed in transformer oil, which is dust-proof, moisture-proof, and salt spray-proof, and suitable for extreme working conditions;

3. Energy saving and automation: The computer-optimized design of the magnetic circuit reduces magnetic loss, and is equipped with an automatic iron unloading mechanism and a correction roller to reduce manual maintenance; it supports centralized control functions and seamlessly connects to intelligent production lines;

4. High magnetic field strength: It provides three levels of super-strong magnetic types, T1 (90mT), T2 (120mT), and T3 (150mT), and the efficiency of removing fine iron parts is increased by more than 30%.

|

|

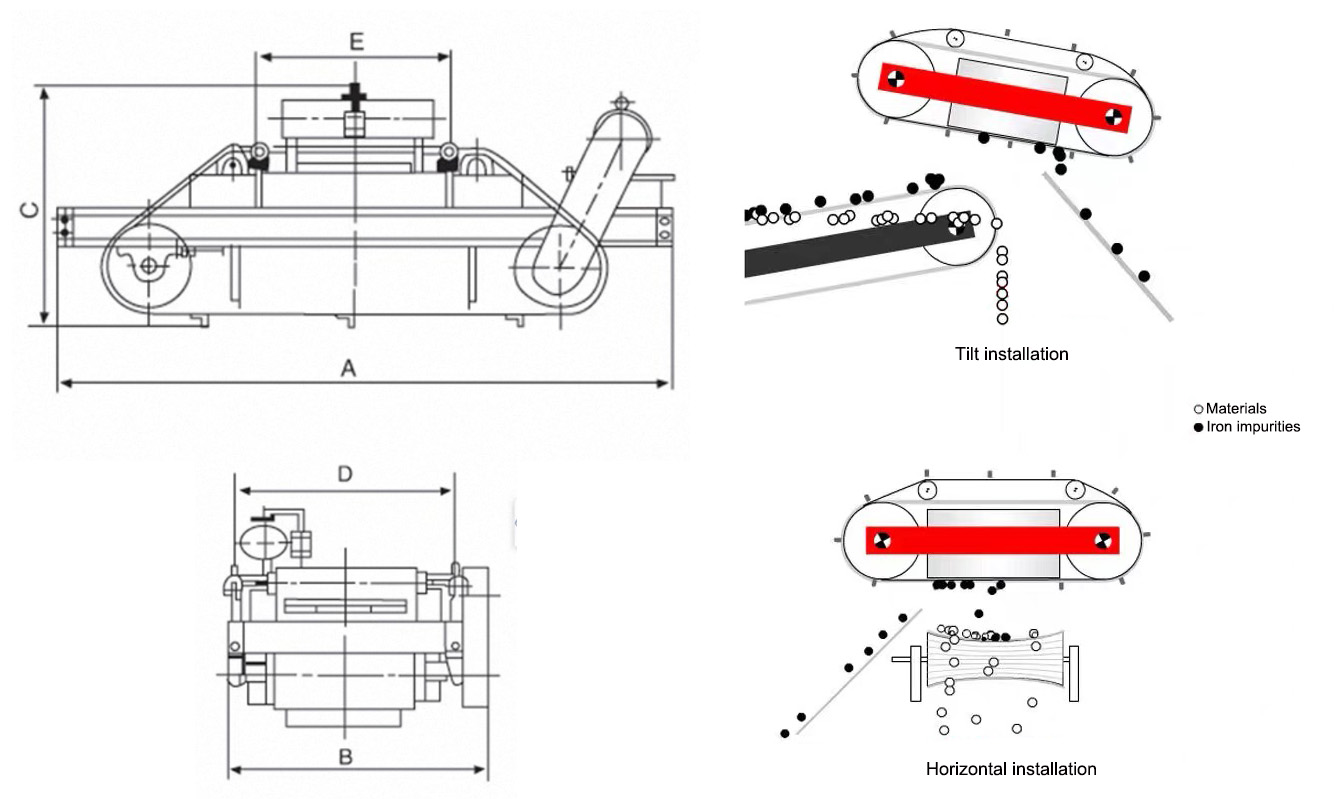

PRODUCT STRUCTURE

Introduction: RCDF oil-water-cooled electromagnetic iron remover consists of five modules: excitation coil, iron core, shell, oil-water cooling system, and expansion tank. The coil adopts three-dimensional layered winding (3-5 layers/group), and the layers are separated by insulating strips to form oil channels; the top of the shell is integrated with an oil pump-driven cooling system, which quickly exchanges heat through the water-cooled clamping cavity; the expansion tank dynamically adjusts the oil volume and eliminates thermal stress.

Working principle: When working, the excitation coil is energized to generate a high-intensity magnetic field, which absorbs ferromagnetic impurities in the material on the conveyor belt. At the same time, the oil pump extracts high-temperature transformer oil (after absorbing the heat of the coil) to the oil-water cooling system for heat exchange with the cooling water; the cooled oil flows back to the shell through the bottom to form a closed loop. This process ensures that the coil operates at a constant temperature and maintains a stable excitation current. The adsorbed iron parts are automatically unloaded through the waist drum-shaped roller, and its deviation correction design prevents the belt from running off. The entire process does not require external air intervention, completely isolating the risk of dust pollution.

TECHNICAL PARAMETERS

| Model | Belt Width(mm) | Required Hanging Height(h≤mm) | Magnetic Strength(≈mT) | Excitation Power(≤kw) | Air-fan Power(kw) | Overall Dimension(mm) | Belt speed(≤m/s) | Weight(kg) | |

| RCDF-10 | T1 | 1000 | 300 | 90 | 6.5 | 0.25 | 1300x1300x1210 | 5.8 | 2600 |

| T2 | 120 | 9.5 | 1300x1300x1250 | 2950 | |||||

| T3 | 150 | 15 | 1350x1350x1280 | 3470 | |||||

| RCDF-12 | T1 | 1200 | 350 | 90 | 9 | 1350x1350x1250 | 2900 | ||

| T2 | 120 | 14 | 1350x1350x1280 | 3500 | |||||

| T3 | 150 | 20 | 1600x1600x1380 | 5400 | |||||

| RCDF-14 | T1 | 1400 | 400 | 90 | 14 | 1350x1350x1280 | 3000 | ||

| T2 | 120 | 20 | 1600x1600x1420 | 5500 | |||||

| T3 | 150 | 29 | 1830x1830x1450 | 7460 | |||||

| RCDF-16 | T1 | 1600 | 450 | 90 | 18 | 1600x1600x1420 | 5400 | ||

| T2 | 120 | 28 | 1830x1830x1450 | 7500 | |||||

| T3 | 150 | 32 | 1950x1950x1480 | 8550 | |||||

| RCDF-18 | T1 | 1800 | 500 | 90 | 26 | 1850x1850x1480 | 7600 | ||

| T2 | 120 | 32 | 1950x1950x1480 | 8600 | |||||

| T3 | 150 | 40 | 2060x2060x1500 | 10500 | |||||

| RCDF-20 | T1 | 2000 | 550 | 90 | 30 | 2000x2000x1480 | 8800 | ||

| T2 | 120 | 39 | 2100x2100x1500 | 10600 | |||||

| T3 | 150 | 41 | 2260x2260x1500 | 12500 | |||||

| RCDF-22 | T1 | 2200 | 600 | 90 | 39 | 2060x2060x1500 | 10500 | ||

| T2 | 120 | 42 | 2260x2260x1520 | 12800 | |||||

| T3 | 150 | 45 | 2500x2500x1520 | 13500 | |||||

| RCDF-24 | T1 | 2400 | 650 | 90 | 40 | 2260x2260x1520 | 13000 | ||

| T2 | 120 | 46 | 2450x2450x1550 | 15200 | |||||

| T3 | 150 | 54 | 2650x2650x1580 | 17500 | |||||

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE