RCDD Self-discharg Electromagnetic Iron Separator

[Overview]:RCDD self-unloading electromagnetic iron separator is a fully automatic iron unloading equipment. It integrates the iron unloading mechanism on the basis of RCDB series electromagnetic iron remover. It generates a strong magnetic field through the excitation coil to absorb ferromagnetic impurities (0.1~50 kg), and uses the belt to automatically throw the iron pieces into the iron collection box. It adopts a self-cooling fully sealed structure (internal filling resin casting), with dustproof, rainproof and corrosion-resistant characteristics, adapting to harsh industrial environments such as high dust and high humidity, and significantly reducing the need for manual intervention.

[Application scenarios]:Widely used in thermal power generation, cement, mining, metallurgy, garbage disposal (construction/industrial waste), and chemical industry. Installed at the head/middle of the belt conveyor, the front section of the crusher or grinder.

ADVANTAGES

Electromagnetic iron separator,Self-cleaning iron separator,RCDD iron separator,RCDD self-discharg electromagnetic iron separator,RCDD iron remover,Self-cleaning iron remover.

1. Reasonable structure, good iron unloading effect.

Reducer, iron unloading belt, roller, main frame and other devices are added on the basis of strong magnetic iron remover. When working, the ferromagnetic material continuously adsorbed on the iron remover is automatically thrown out through the rotation of the iron unloading belt to achieve the purpose of automatic iron unloading.

2. Effective temperature control and high heat dissipation efficiency.

The iron remover adopts corrugated heat dissipation fins, which greatly increases the heat dissipation area of the iron remover and improves the heat dissipation efficiency. When the iron remover works continuously for a long time, the temperature rises slowly and the temperature can be effectively controlled.

3. Resin casting, good sealing performance.

The interior of the iron remover is cast with electrical resin and self-cooling sealing structure, which has excellent sealing ability and good practicality.

4. Deep magnetic penetration and good magnetic force.

The internal magnetic circuit of the iron remover adopts computer simulation design and perfect double-pole structure. The structure is reasonable, the probability of equipment failure is reduced, and the iron remover can operate for a long time without failure in harsh environments.

5. Intelligent control, simple and convenient operation.

Adopting intelligent operating system, the operation method is simple, convenient and easy to master. No manual iron removal is required. There is magnetism when the power is on and demagnetization when the power is off, which is convenient for later maintenance.

|

|

|

|

|

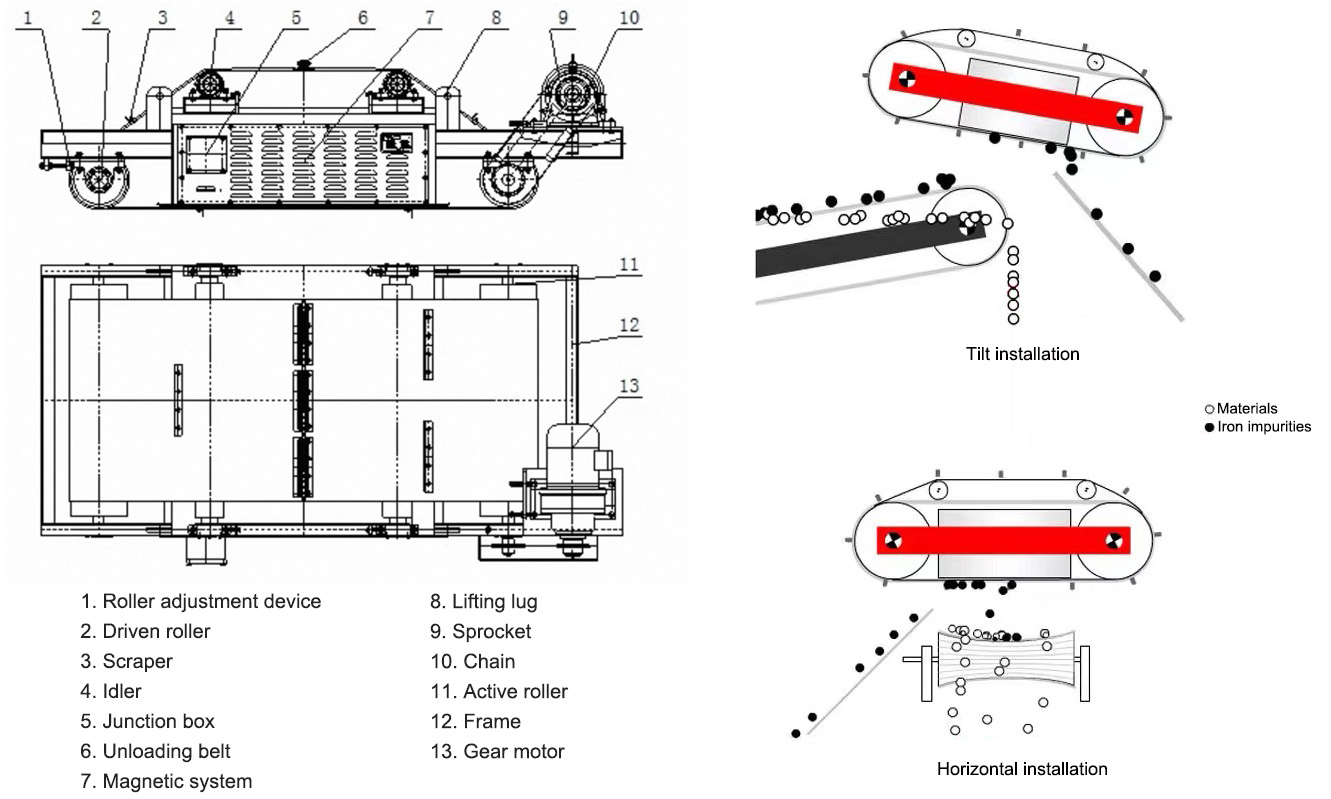

PRODUCT STRUCTURE

Introduction: RCDD electromagnetic iron separator consists of two parts: the electromagnetic iron removal body and the iron unloading mechanism. The unloading mechanism includes a reduction motor, a roller, an unloading belt and a scraper. The magnetic circuit is optimized by computer to form a hemispherical magnetic field with a large magnetic penetration depth (up to 1.5 times that of ordinary equipment) and a magnetic field strength of ≥70mT. Typical models such as RCDD-10 have an excitation power of ≤5kW, an adaptable bandwidth of 1000mm, a lifting height of 300mm, support continuous operation and a service life of more than 15 years.

Working principle: After power is turned on, the excitation coil generates a strong magnetic field. When the material on the conveyor belt passes, the iron impurities are adsorbed to the surface of the unloading belt; the belt continues to run to take the iron pieces away from the magnetic field area, and falls into the iron collection box under the action of gravity, realizing fully automatic unloading. No power outage or manual intervention is required throughout the process to ensure continuous operation of the production line.

TECHNICAL PARAMETERS

| Model | Belt width(mm) | Requred Hanging Height(h≤mm) | Magnetic Strength(≥mt) | Material Thickness(≤mm) | Excitation Power(≤kw) | Air-fan Power(kw) | Belt speed(≤m/s) | Weight(kg) | Overall Dimension(mm) |

| RCDD-5 | 500 | 150 | 60 | 100 | 1.0 | 1.5 | 4.5 | 950 | 2020*1040*775*853*1000 |

| RCDD-6 | 600 | 175 | 60 | 130 | 1.8 | 1.5 | 4.5 | 1380 | 2140*1100*800*910*1100 |

| RCDD-6.5 | 650 | 200 | 70 | 150 | 2.0 | 2.2 | 4.5 | 1490 | 2275*1190*820*988*1250 |

| RCDD-8 | 800 | 250 | 70 | 200 | 3.0 | 2.2 | 4.5 | 1770 | 2540*1480*865*1287*1350 |

| RCDD-10 | 1000 | 300 | 70 | 250 | 4.5 | 3.0 | 4.5 | 2380 | 2750*1635*940*1420*1400 |

| RCDD-12 | 1200 | 350 | 70 | 300 | 5.8 | 3.0 | 4.5 | 3170 | 3000*1800*1010*1580*1700 |

| RCDD-14 | 1400 | 400 | 70 | 350 | 6.7 | 4.0 | 4.5 | 4800 | 3500*2050*1050*1800*2000 |

| RCDD-16 | 1600 | 450 | 70 | 400 | 9.5 | 5.5 | 4.5 | 6300 | 3900*2450*1180*2200*2350 |

| RCDD-18 | 1800 | 500 | 70 | 450 | 12.5 | 7.5 | 4.5 | 7800 | 4400*2850*1290*2600*2800 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE