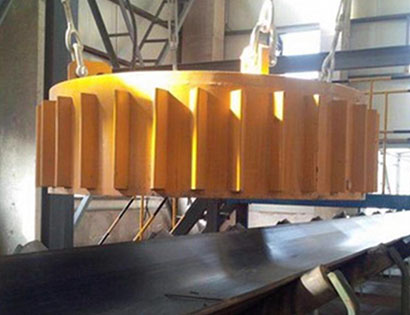

RCDB Suspension Electromagnetic Iron Separator

[Overview]:RCDB suspended electromagnetic iron separator is an iron removal device that uses electromagnetic coils to generate a strong magnetic field. It is designed to remove ferromagnetic impurities mixed in non-magnetic materials. It adopts a fully sealed self-cooling structure (filled with electrical resin or magnesium oxide inside), has dustproof, rainproof, corrosion-resistant characteristics, and is suitable for harsh industrial environments.

[Application scenarios]:Widely used in the processing of dry loose materials, including: thermal power generation, coal, cement, mining, metallurgy, chemical industry, glass, building materials, ceramics, etc.; installed on belt conveyors, vibrating feeders or unloading chutes to remove iron parts in raw materials to improve material purity and recover iron impurities.

ADVANTAGES

Electromagnetic separator,Conveyor belt iron separator,RCDB suspension electromagnetic iron separator,Suspension electromagnetic separator,Electromagnetic suspended iron separator,RCDB iron separator.

1. Excellent magnetic effect: optimized magnetic circuit design, deep magnetic penetration, strong suction (can pick up 35kg iron pieces), iron removal rate ≥ 95%;

2. Stable and durable: fully sealed structure + resin cast coil, waterproof and dustproof, high insulation, life of more than 15 years;

3. Energy saving and temperature control: by increasing the number of coil turns and reducing the current density, significantly reduce heat generation (temperature rise ≤ 80℃) and avoid magnetic attenuation;

4. Easy maintenance: natural cooling does not require additional devices, manual iron unloading design reduces the failure rate, and supports PLC automatic control upgrade.

|

|

|

|

|

PRODUCT STRUCTURE

Introduction: RCDB electromagnetic separator consists of core components such as electromagnetic coils, magnetic cores, magnetic pole filling materials and junction boxes. The magnetic circuit is optimized by computer, with a large magnetic penetration depth and uniform magnetic field distribution (standard magnetic induction intensity ≥ 70mT, super strong type can reach 150mT). Natural cooling or heat pipe assisted cooling technology is used to control the temperature rise within 70℃~80℃ to ensure long-term stable operation. It needs to be installed with a belt conveyor, and the iron is unloaded manually. The working mode is continuous.

Working principle:After the DC power supply is turned on, the excitation coil generates a high-intensity magnetic field. When the material passes under the iron remover, the mixed ferromagnetic materials (such as mechanical iron blocks, bolts, etc.) are adsorbed to the surface of the magnetic pole under the action of the magnetic field force. After the machine is shut down, the power is turned off for demagnetization, and the adsorbed iron impurities are manually removed, or the electric trolley is used to move away from the conveyor belt to the iron collecting box for unloading.

TECHNICAL PARAMETERS

| Model | Belt width(mm) | Hanging Height(h≤mm) | Magnetic Strength(≥mt) | Material Thickness(≤mm) | Driving Power(≤kw) | Weight(kg) | Overall Dimension(mm) |

| RCDB-3 | 300 | 75 | 50 | 50 | 0.4 | 185 | 210*250*400*280 |

| RCDB-4 | 400 | 100 | 50 | 70 | 0.6 | 300 | 240*280*500*400 |

| RCDB-5 | 500 | 150 | 60 | 90 | 1 | 430 | 280*325*610*450 |

| RCDB-6 | 600 | 175 | 70 | 120 | 1.6 | 580 | 280*325*710*500 |

| RCDB-6.5 | 650 | 200 | 70 | 150 | 2 | 680 | 280*325*816*640 |

| RCDB-8 | 800 | 250 | 70 | 200 | 3.6 | 950 | 310*355*960*780 |

| RCDB-10 | 1000 | 300 | 70 | 250 | 5 | 1520 | 310*360*1200*920 |

| RCDB-12 | 1200 | 350 | 70 | 300 | 6.8 | 2250 | 310*365*1400*1000 |

| RCDB-14 | 1400 | 400 | 70 | 350 | 9 | 2950 | 405*485*1650*1400 |

| RCDB-16 | 1600 | 450 | 70 | 400 | 13 | 4800 | 460*540*1900*1650 |

| RCDB-18 | 1800 | 500 | 70 | 450 | 18 | 6900 | 530*610*2150*1800 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE