Wet Belt Magnetic Separator

[Overview]:Wet belt magnetic separator is aslo called permanent magnet flat type magnetic separator. It is a kind of permanent magnetic mineral separation equipment with high efficiency, energy saving and easy operation. Its core advantage is to continuously capture fine-grained weak magnetic minerals from the slurry by using a specially designed plate-shaped high-gradient permanent magnetic system. It plays an important role in the field of mineral purification and is one of the indispensable key equipment for the separation of weak magnetic minerals. It is a permanent magnetic separation equipment comparable to electromagnetic separators, with a magnetic field strength of up to 1.5T.

[Scope of application]:It is suitable for iron removal and purification of non-metallic ores such as quartz sand, potassium-sodium feldspar, nepheline, and kaolin. It is also suitable for the separation of weak magnetic metal ores such as hematite, limonite, manganese ore, wolframite, and tantalum-niobium ore. It can also be used to recover useful metal minerals from tailings.

ADVANTAGES

Wet belt magnetic separator,Belt type magnetic separator,Wet flat plate magnetic separator,Flat magnetic separator,High field strength magnetic separator.

1、High-performance NdFeB magnetic materials are selected, and the magnetic circuit is uniquely designed. The highest magnetic field strength on the surface can reach 15000Gs,which is comparable to high-gradient electromagnetic magnetic separators.

2、Comnared with other nermanent maanetic senarators.the maanetic field sweening area is larger and the iron removal effect is better.

3、The slope of the plate surface is adjustable, and adjusting the slope according to the material condition can achieve the best iron removal effect.

4、The belt speed can be adiusted by freauency conversion.Adiustina the belt speed according to the material can achieve better iron removaleffect.

5、Wear-resistant canvas is used as the conveyor belt which greatly increases the service life of the conveyor belt.

6、Compared with other high gradient vertical ring magnetic separators itsaves electricity and energy.

7、The ore is eauipped with a uniform feedina device: the tailinas are eauipped with a manetic device for automatic cleaning and adsorption.

|

|

|

|

|

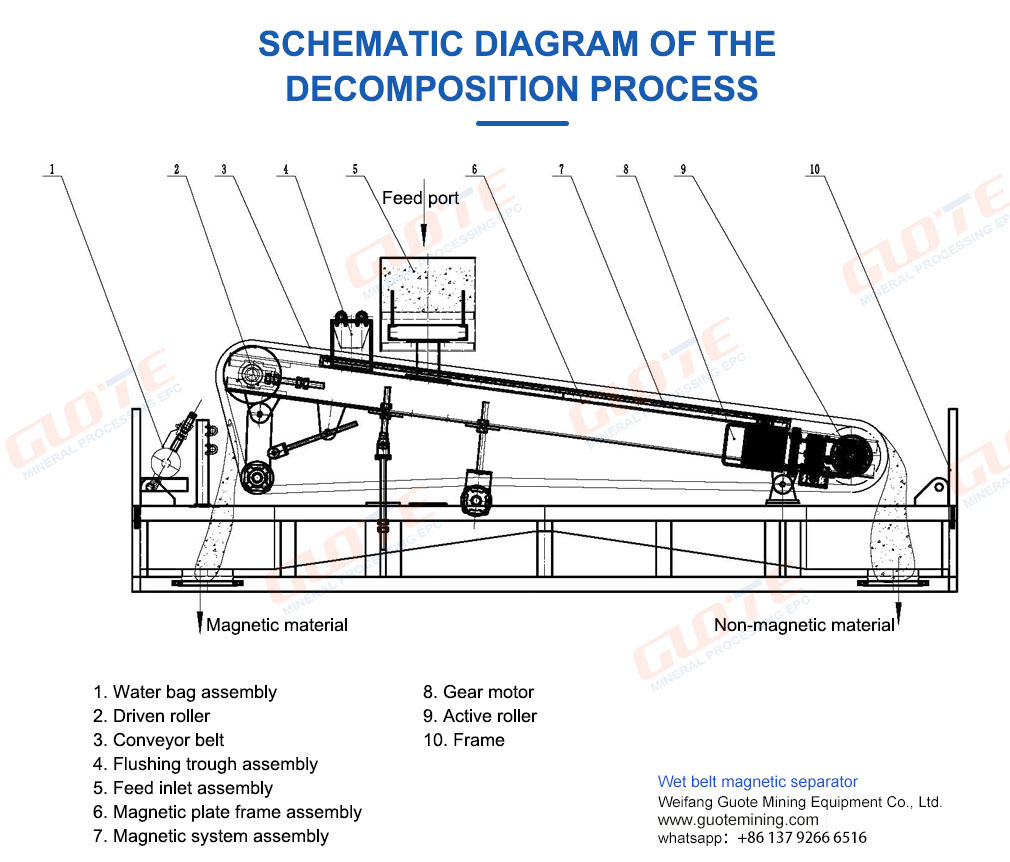

PRODUCT STRUCTURE

Introduction:Wet belt magnetic separator is a high-gradient, high-field strength magnetic separation equipment newly developed by Guote Mining Equipment. The magnetic system of the magnetic separator is made of high-quality rare earth magnetic steel extrusion. The equipment has a high magnetic field strength. It integrates physical mechanics, fluid mechanics, and magnetism. It can select weakly magnetic minerals according to the different magnetic properties of the ore. It is mainly suitable for the removal of impurities and purification of fine-grained non-metallic ores less than 1.2 mm, such as quartz, feldspar, nepheline ore, and kaolin. It can also be used for wet separation of red ore (hematite, limonite, siderite, etc.), manganese ore, ilmenite, wolframite and other weakly magnetic metal ores, and separation of black and white tungsten, and separation of black tungsten from cassiterite.

Working principle:The ore pulp enters the uniform distribution device of the wet belt magnetic separator through the feed pipe, and after being fully dispersed, it is evenly sprinkled on the belt on the upper part of the magnetic plate. Under the action of gravity, the pulp flows downward along the tilt direction of the magnetic plate. The magnetic substances contained in the pulp are firmly adsorbed on the belt under the strong magnetic field provided by the magnetic plate. The belt rotates along the tilt of the magnetic plate driven by the motor, and at the same time, the adsorbed magnetic substances are brought into the iron unloading area. The magnetic substances enter the magnetic material hopper under the flushing of the flushing water and are collected. The non-magnetic pulp continues to flow downward along the magnetic plate and flows into the non-magnetic material hopper to be collected.

TECHNICAL PARAMETERS

| Model | Processing capacity (t/h) | Magnetic field strength (GS) | Slurry concentration | Belt speed (r/min) | Motor power (kw) | Weight(t) | Plate magnet effective size (mm) |

| GTGB0815 | 8-10 | 15000 | 10%-30% | 2-8 | 2.2 | 1.2 | 800×1500 |

| GTGB1020 | 15-20 | 15000 | 10%-30% | 2-8 | 2.2 | 1.6 | 1000×2000 |

| GTGB1520 | 20-25 | 15000 | 10%-30% | 2-8 | 2.2 | 3 | 1500×2000 |

| GTGB2025 | 25-30 | 15000 | 10%-30% | 2-8 | 3 | 3.6 | 2000×2500 |

| GTGB2230 | 30-35 | 15000 | 10%-30% | 2-8 | 4 | 4.5 | 2200×3000 |

| GTGB2525 | 35-40 | 15000 | 10%-30% | 2-8 | 4 | 4.7 | 2500×2500 |

| GTGB2530 | 35-40 | 15000 | 10%-30% | 2-8 | 4 | 5.6 | 2500×3000 |

| GTGB3025 | 40-50 | 15000 | 10%-30% | 2-8 | 4 | 6.7 | 3000×2500 |

RELATED PRODUCTS

RELATED NEWS

- Weifang Guote Mining Equipment Co., Ltd.

- Repair and maintenance of mining machinery and equipment.

- 2024 Guote Mining Equipment Promotional Film

- Process characteristics and process of quartz stone pickling

- What is a magnetic separator? What types of magnetic separators are there?

- 2024 Vietnam International Mining and Mineral Resources Recycling Exhibition

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE