Dry Roller Magnetic Separator

[Overview]:Dry roller magnetic separator is a device that uses a permanent magnetic roller to generate a magnetic field and sorts materials according to their magnetic strength without using a liquid medium (such as water). It consists of multiple layers of magnetic rollers and has unique advantages in processing dry, powdered or small particle materials.

[Scope of application]: Dry pre-selection of weakly magnetic ores such as ceramics, glass, refractory materials, abrasives and grinding tools, and limonite, and dry pre-selection of manganese ore.

ADVANTAGES

Dry roller magnetic separator,Roller dry magnetic separator,Roller magnetic separator,Permanent magnet dry roller magnetic separator,Permanent magnet multi-roller magnetic separator,High field roller dry magnetic separator,Multiroller magnetic separator.

1.The equipment can be customized to be closed, equipped with a dust removal port, and dust is discharged in a centralized manner, meeting environmental protection requirements;

2.Automatic cleaning of weak magnetic oxides can ensure long-term trouble-free operation.

3.The controllable feeding system ensures the uniformity of the material when it flows through the magnetic field area. The conveyor belt used by the magnetic roller is made of special materials with good wear resistance.

4.The magnetic roller adopts a concentrated magnetic composite magnetic system, and the magnetic field strength can reach 15000GS, with a higher gradient.

5.The magnetic system of the magnetic drum can be made into a flipping type, and the removal rate is greatly improved. The speed of the drum and the magnetic roller is frequency-controlled to adapt to wider particle size and output requirements.

6.The drum adopts a new type of compensation magnetic machine type magnetic system, and the magnetic field strength can reach 8000GS, with higher magnetic field strength and stronger suction.

7. Reasonable combination of permanent magnetic drum and permanent magnetic roller can achieve better sorting effect.

|

|

|

|

|

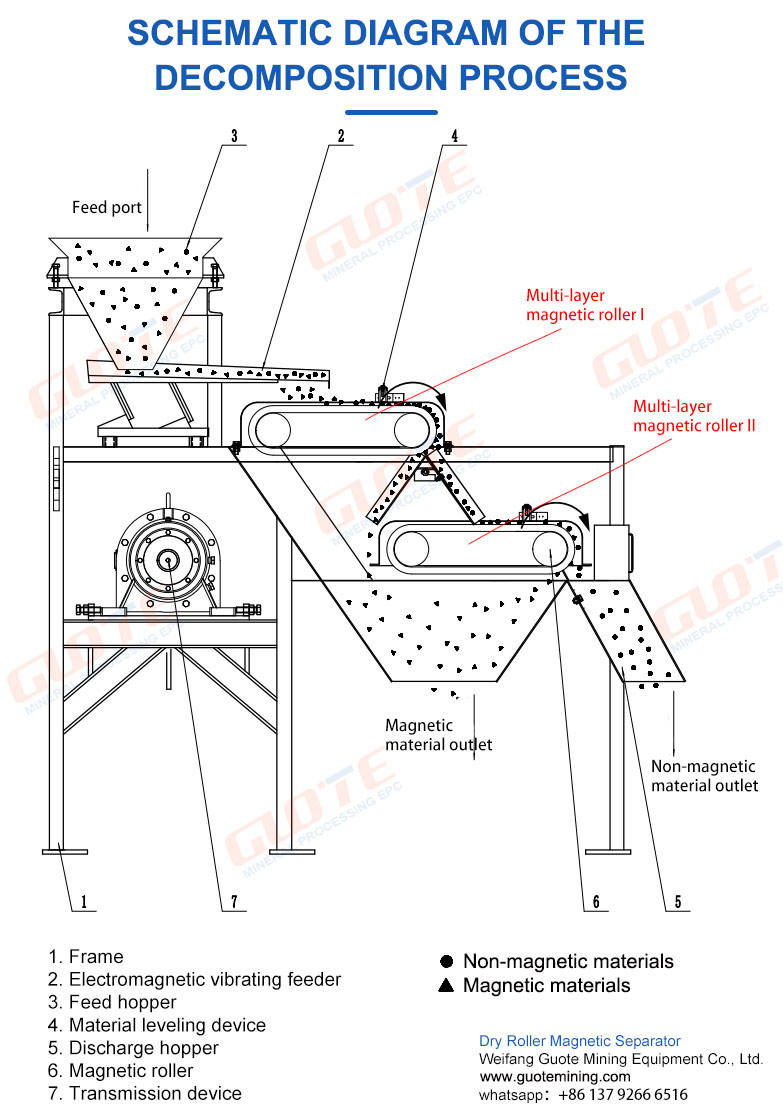

PRODUCT STRUCTURE

Introduction:Dry Roller Magnetic Separator can remove weak magnetic impurities from granular or coarse powder materials, and is used for the purification of non-metallic minerals, chemicals, foods, and biology such as ceramics, glass, refractory materials, abrasives, etc., as well as the dry pre-selection of weak magnetic ores such as hematite and limonite, and the dry beneficiation of manganese ore.The dry roller magnetic separator is an efficient, economical and environmentally friendly equipment for magnetic separation of dry coarse particles. It plays an irreplaceable role in the purification and removal of non-metallic minerals, pre-selection of ores in water-scarce areas, and recycling of solid waste. Its core value lies in saving water, energy and avoiding water pollution. When selecting, it is necessary to consider its applicability based on the particle size, moisture, magnetism, processing volume and product requirements of the material, and attach great importance to dust control.

Working process:The granular material falls into the vibrating feeding device through the feeding funnel and is evenly vibrated to the working area of the permanent magnetic roller. The magnetic particles are firmly adsorbed on the surface of the magnetic roller. After being brought into the non-magnetic field area, they are discharged through the magnetic material discharge port. Under the action of gravity and inertia, the non-magnetic material falls into the magnetic roller mechanism for the next level of magnetic separation. The conveyor belt transports the material to the magnetic roller. Under the action of the magnetic field of up to 18000GS, the weak magnetic particles are firmly adsorbed on the surface of the magnetic roller, and then sent to the non-magnetic field area by the conveyor belt and discharged through the magnetic material discharge port. The non-magnetic material continues to enter the next level of the magnetic roller mechanism. After multiple selections, the non-magnetic particles are discharged through the non-magnetic material discharge port at the front of the equipment.

TECHNICAL PARAMETERS

| Model | Magnetic roller length (mm) | Magnetic roller field strength (GS) | Magnetic drum field strength (GS) | Belt thickness (mm) | Material particle size (um) | Processing capacity (t/h) | Drum drive power(kw) | Magnetic roller drive power(kw) |

| GCT/F3-Ⅰ | 300 | 15000-20000 | 4000-10000 | 0.1-2 | 83-5000 | 0.4-0.6 | 0.75*2 | 0.55 |

| GCT/F3-Ⅱ | 1.1 | |||||||

| GCT/F5-Ⅰ | 500 | 15000-20000 | 4000-10000 | 0.1-2 | 83-5000 | 0.8-1 | 0.75*2 | 0.55 |

| GCT/F5-Ⅱ | 1.1 | |||||||

| GCT/F8-Ⅰ | 800 | 15000-20000 | 4000-10000 | 0.1-2 | 83-5000 | 1.2-2 | 1.1*2 | 0.55 |

| GCT/F8-Ⅱ | 1.1 | |||||||

| GCT/F10-Ⅰ | 1000 | 15000-20000 | 4000-10000 | 0.1-2 | 83-5000 | 2-3.5 | 1.5*2 | 0.75 |

| GCT/F10-Ⅱ | 1.5 | |||||||

| GCT/F12-Ⅰ | 1200 | 15000-20000 | 4000-10000 | 0.1-2 | 83-5000 | 4-7 | 2.2*2 | 0.75 |

| GCT/F12-Ⅱ | 1.5 | |||||||

| GCT/F15-Ⅰ | 1500 | 15000-20000 | 4000-10000 | 0.1-2 | 83-5000 | 7-10 | 3*2 | 1.1 |

| GCT/F15-Ⅱ | 2.2 | |||||||

| GCT/F15-Ⅲ | 3 |

RELATED PRODUCTS

RELATED NEWS

- Weifang Guote Mining Equipment Co., Ltd.

- Repair and maintenance of mining machinery and equipment.

- 2024 Guote Mining Equipment Promotional Film

- Process characteristics and process of quartz stone pickling

- What is a magnetic separator? What types of magnetic separators are there?

- 2024 Vietnam International Mining and Mineral Resources Recycling Exhibition

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE