Ore Washing Machine

[Overview]:The drum stone washer, also known as a cylindrical ore washer, is a horizontally mounted mineral cleaning machine. Through a combination of drum rotation, mechanical shedding, and hydraulic scouring, it removes clay, silt, and impurities from the ore surface, achieving physical separation between the ore and impurities. It is primarily used for desliming aggregates in sand and gravel.

[Application Scenarios]:Widely used in the mining, building materials, and infrastructure sectors, for example: 1. Mineral processing: Cleaning high-mud metal ores such as iron ore and manganese ore to improve pre-selection grade; also for pre-purification of non-metallic ores such as quartz sand and kaolin. 2. Building materials and infrastructure: Cleaning construction sand and gravel aggregates and manufactured sand to ensure concrete strength. Widely used in high-speed rail, highway, and water conservancy projects. 3. Resource recovery: Processing tailings, waste rock, or coal gangue, and desliming and grading sand and gravel in precast plants.

ADVANTAGES

1. Efficient Cleaning: The synergistic effect of mechanical shedding and high-pressure spraying achieves a cleaning rate of up to 98%-99%, significantly improving ore grade.

2. High Processing Capacity: The maximum feed size reaches 300mm, and a single unit can process up to 500 tons/hour, meeting the needs of large-scale production lines.

3. Energy Saving and Environmental Protection: The circulating water system reduces fresh water consumption by 30%, and wastewater can be reused after sedimentation. Frequency conversion technology reduces energy consumption by 30%.

4. Durable and Low-Maintenance: High-chromium alloy blades and wear-resistant rubber liners extend service life by 50%, and the modular design simplifies maintenance.

5. Integrated Design: The equipment is highly integrated into the overall frame, requiring only a leveled foundation and sedimentation tank for easy installation.

|

|

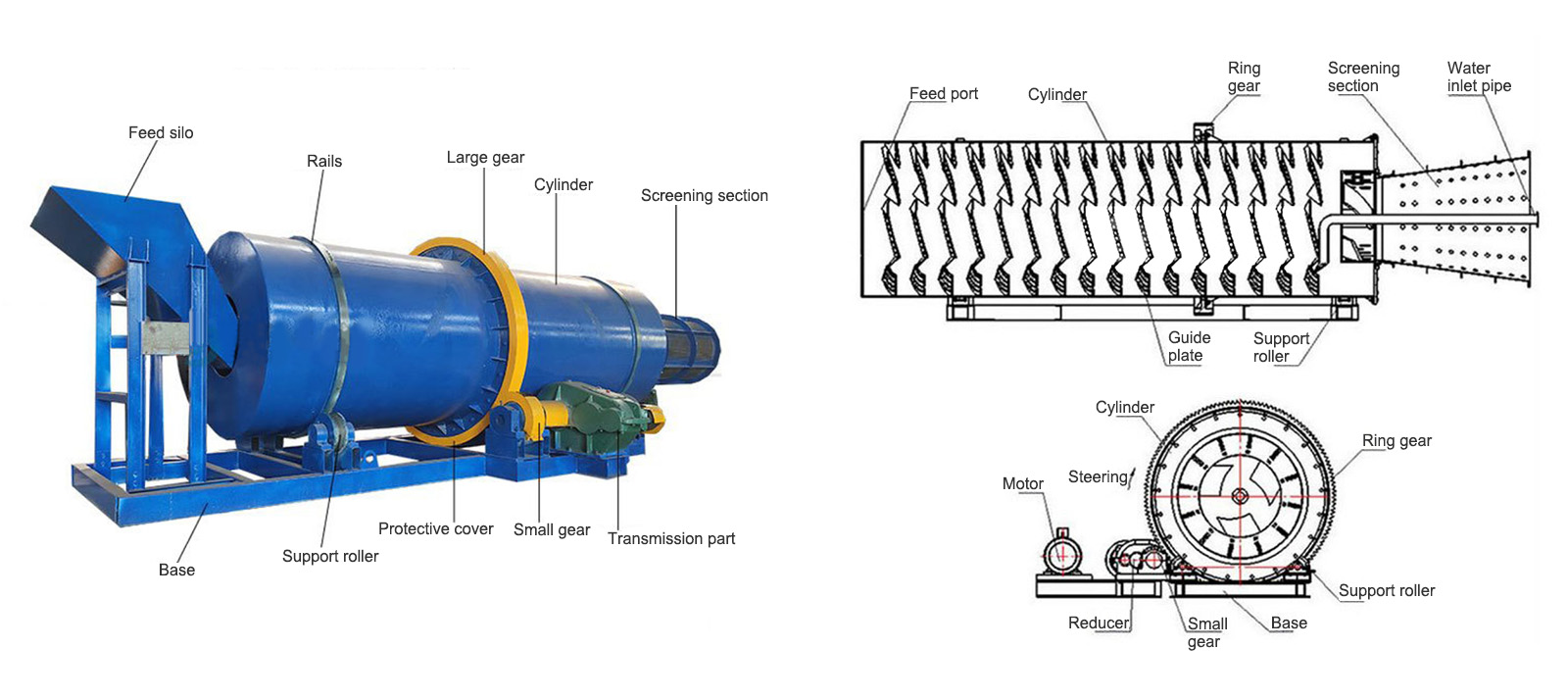

PRODUCT STRUCTURE

Introduction:A drum stone washer primarily consists of a drum, a drive system (motor + reducer + gears), wear-resistant lining, a support pulley, and a water supply unit. It comes in two types: 1. Drum type: a basic model focused on desludging and cleaning; 2. Drum with screen grate type: an additional grading function, capable of outputting products in two grades: +40mm and -40mm. The -40mm material can be further processed by a spiral washer to ±2mm.

Working Principe:1. Feeding and Rotary Dropping: Mud-laden material enters the slow-rotating drum through the feed inlet and is repeatedly lifted and dropped by the inclined wear-resistant lining inside, removing surface impurities through friction. 2. Hydraulic Flushing: High-pressure water (forward/reverse) sprays the material, creating a vortex that removes the mud. The wastewater is discharged through holes in the drum or an overflow outlet to a sedimentation tank for reuse. 3. Grading and Discharge: Clean ore moves to the discharge end, where it is dewatered by a drum screen before being discharged. Screen grate models also perform particle size classification (e.g., ±40mm).

TECHNICAL PARAMETERS

| Model | Cylinder diameter*length (m) | Maximum cleaning material (mm) | Production capacity (t/h) | Cylinder speed (r/min) | Host power (kw) | Equipment weight (kg) |

| GTX-1530 | Φ1.5*3.0 | 50 | 70-140 | 30 | 55 | 17800 |

| GTX-1836 | Φ1.8*3.6 | 80 | 120-200 | 25 | 75 | 24700 |

| GTX-2145 | Φ2.1*4.5 | 150 | 180-250 | 21 | 110 | 32618 |

| GTX-2450 | Φ2.4*5.0 | 200 | 230-300 | 18 | 160 | 48700 |

| GTX-2760 | Φ2.7*6.0 | 250 | 280-420 | 16 | 220 | 67200 |

| GTX-3075 | Φ3.0*7.5 | 300 | 400-500 | 15 | 2*185 | 99860 |

RELATED PRODUCTS

RELATED NEWS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE