Linear Vibrating Screen

[Overview]:Linear vibrating screen is a screening device driven by dual vibration motors. Its core feature is that the material moves linearly on the screen surface in a jumping manner, achieving efficient screening and grading. The screen machine drives the screen body to vibrate linearly through the centrifugal force generated by the eccentric block, which is suitable for non-sticky particles or powdered materials. The equipment adopts a modular design and supports 1-5 layers of screen configuration. It can screen 2-7 products of different particle sizes at the same time. The screening accuracy is as high as 96% or more, and the fully enclosed structure effectively prevents dust from spilling.

[Application scenarios]:Widely used in industrial particle grading and solid-liquid separation, mining and metallurgy: quartz sand particles, tailings dry discharge, etc.; chemical and building materials: screening urea, fertilizers, limestone, etc.; food and medicine: fine screening of starch, salt, Chinese medicine powder, etc., to meet sanitary sealing requirements; environmental protection and energy: drilling mud solid control, sewage treatment and recycling of renewable resources.

ADVANTAGES

1. High Efficiency and Energy Saving: Dual motors provide powerful excitation force, increasing processing capacity by 30%-50% and reducing energy consumption by 30%;

2. Optimized Structure: The modular design supports quick screen changes, and the ball-shaped screen cleaning system reduces clogging and extends screen life;

3. Environmentally Friendly and Low Noise: The fully enclosed body prevents dust from escaping, and rubber springs for shock absorption keep noise levels to ≤75dB, improving the working environment;

4. Flexible Adaptability: The screen surface inclination and amplitude are adjustable to accommodate different material characteristics and support automated assembly line operation.

|

|

PRODUCT STRUCTURE

Introduction: The linear vibrating screen consists of a screen box, a vibrating motor, vibration damping springs, a bracket, and multiple layers of screen mesh. The screen box is welded from steel plates to ensure rigidity, and the screen mesh can be made of stainless steel, polyurethane, or nylon. The vibrating motor drives the vibrator via a V-belt or direct drive, generating linear motion. The vibration frequency can be adjusted via a frequency converter to meet varying production requirements.

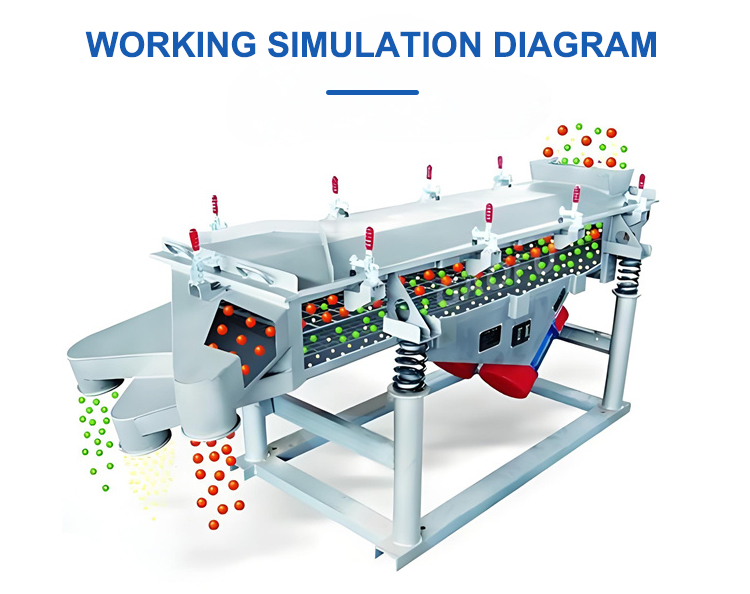

Working principle: The equipment is based on the synchronous counter-rotation of dual motors. The exciting force generated by the eccentric block is offset in the direction parallel to the motor shaft, and the vertical direction is superimposed as a resultant force, driving the screen body to vibrate periodically back and forth in a straight line. The material on the screen surface is acted upon by the combined force of the exciting force and gravity, and moves forward in a parabolic jump. Particles smaller than the screen hole pass through the screen and fall, while coarse particles continue to move forward to the discharge port. The screen surface inclination and vibration frequency work together to control the material movement speed and screening rate, achieving precise classification.

TECHNICAL PARAMETERS

| Model | Number of layers | Screen surface size (mm) | Screen mesh number | Feeding size (mm) | Processing capacity (t/h) | Power (kw) | Double amplitude (mm) | Frequency (times/min) | Screen surface inclination (degrees) |

| GDS-1030 | 1-5 | 1000X3000 | 2-120 | <20 | <2 | 1.1X2 | 6-10 | 1460/960 | 0-10 |

| GDS-1240 | 1-5 | 1200X4000 | 2-120 | <20 | <3 | 1.5X2 | 6-10 | 1460/960 | 0-10 |

| GDS-1530 | 1-5 | 1500X3000 | 2-120 | <20 | <5 | 2.2X2 | 6-10 | 1460/960 | 0-10 |

| GDS-1545 | 1-5 | 1500X4500 | 2-120 | <20 | <5 | 3X2 | 6-10 | 1460/960 | 0-10 |

| GDS-1840 | 1-5 | 1800X4000 | 2-120 | <20 | <7 | 4X2 | 6-10 | 1460/960 | 0-10 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE