Wet High Intensity Magnetic Separator

[Overview]:Wet high intensity magnetic separator(WHIMS)is also called high gradient vertical ring magnetic separator ,it is a core equipment for the separation of weak magnetic minerals and the removal of iron from non-metallic ores. Its technical principles and application performance have shown significant advantages in many fields. With its vertical rotating ring anti-blocking design, high gradient magnetic field generation capability and intelligent control, this equipment has become the core equipment for mineral processing.Magnetic separation equipment with the strongest magnetic field.

[Scope of application]:Ore dressing of weak magnetic minerals such as hematite, limonite, siderite, ilmenite, manganese ore, wolframite, rare earth ore, tantalum-niobium ore; secondary resource recycling of red mud ore, smelting steel slag, gas ash, fly ash, slag, etc. Purification of non-metallic ores such as feldspar, quartz sand, kaolin, nepheline, fluorite, sillimanite, spodumene, barite, andalusite, talc, zircon, bentonite, and magnesite.

ADVANTAGES

1. High-Efficiency Sorting: Unique magnetic media with a high induction magnetic field. Developed by Guote Mining Equipment, the magnetic media boasts a patented product with an induction magnetic field strength exceeding 2.0T. The high-gradient magnetic field is 10–100 times stronger than conventional equipment, achieving high concentrate recovery and high grade.

2. Cooling System: The oil-water composite cooling system utilizes an oil-water heat exchange principle, using flushing water to quickly remove heat generated by the coils, keeping coil temperature rise below 25°C and maintaining a more stable magnetic field.

3. Anti-clogging and Energy Saving: The vertical swivel recoil design completely eliminates magnetic media clogging, reducing energy consumption by 20%–50% compared to conventional equipment.

4. Intelligent and Stable: Equipped with a fault diagnosis system and remote control system, variable frequency drive to adjust swivel speed and pulsation frequency, and automatic liquid level compensation, the equipment achieves intelligent operation.

5. Highly Adaptable: Compatible with slurries with a particle size of ≤2mm and large concentration fluctuations. The corrosion-resistant coil design is suitable for harsh operating conditions.

6. Pulse Device: Depending on the material’s characteristics, an optional pulse device can be added for enhanced flushing and separation performance, while also conserving water.

(Key Words:Wet high intensity magnetic separator, Vertical pulsating magnetic separator, Vertical ring magnetic separator, High gradient magnetic separator.)

|

|

|

|

|

PRODUCT STRUCTURE

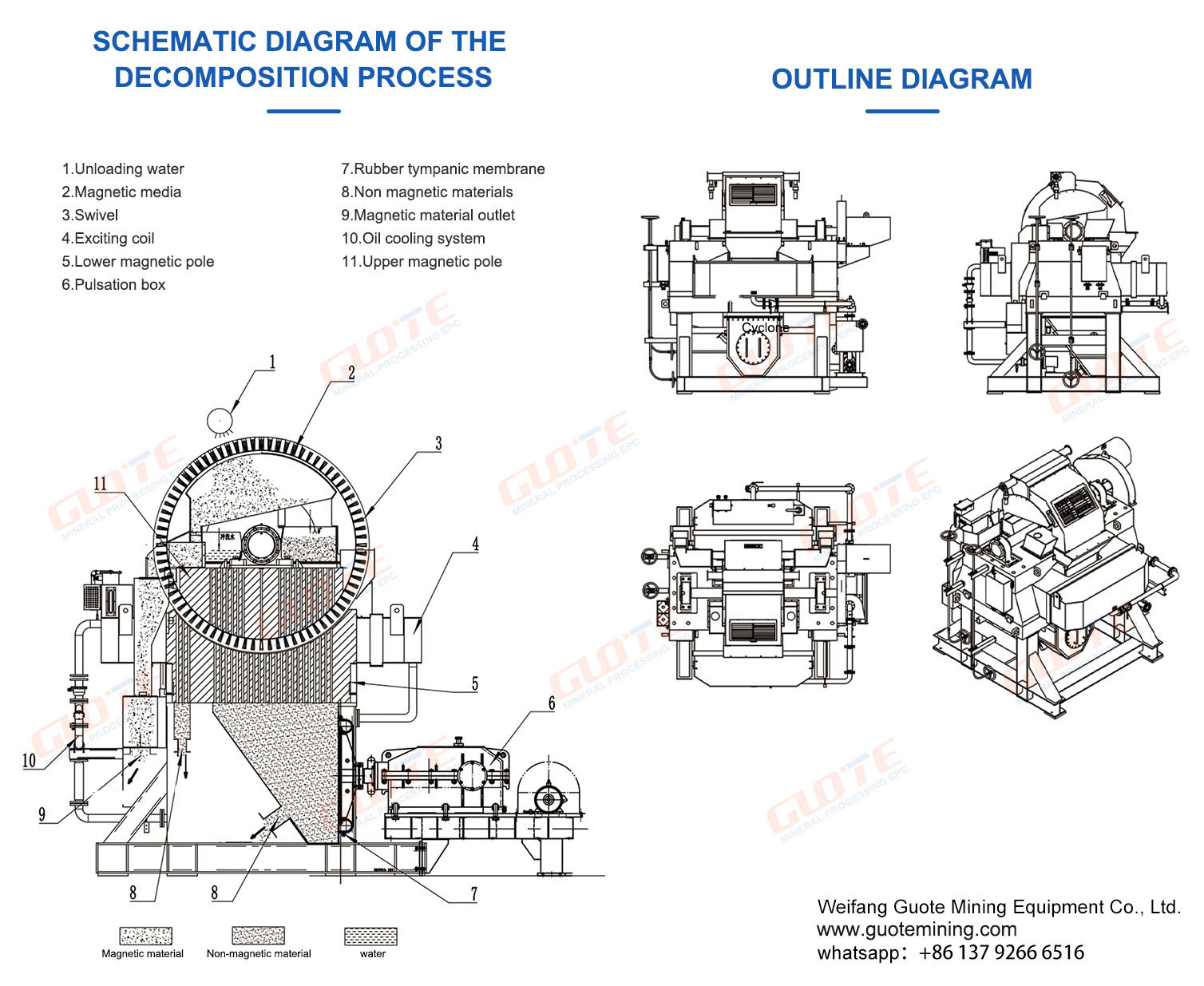

Intorduction:The wet high intensity magnetic separator(WHIMS) with its three key breakthroughs—vertical rotation, anti-clogging, high field strength, and low energy consumption—has become a benchmark for the separation of weakly magnetic minerals and the purification of non-metallic materials. The equipment primarily consists of a rotating ring, excitation coil, iron yoke, high-frequency vibration mechanism, flushing device, and cooling system. My company focused on magnetic separation equipment for more than 10 years,The largest model of our vertical ring magnetic separator boasts a rotating ring diameter of 5 meters, marking Guote Mining Equipment’s global leadership in high-end magnetic and electric mineral separation equipment.

Working principle:The slurry enters the feed hopper through the feed pipe. It flows through the upper magnetic field gap and through the rotating ring. The inductive magnetic medium, composed of high-permeability stainless steel rods within the rotating ring, is magnetized in the background magnetic field, creating a high-gradient magnetic field on the surface of the medium. Magnetic particles in the slurry are attracted to the surface and, as the rotating ring rotates, are carried to the top, where the magnetic field is neutral. Pressurized water flushes the magnetic material into the magnetic hopper, while non-magnetic particles flow through the gap below the magnetic pole into the non-magnetic hopper, achieving separation. The magnetic medium at the bottom of the rotating ring is submerged in the slurry. Simultaneously with slurry injection, the stroke box mounted on one side of the tailings box continuously reciprocates, causing the slurry in the sorting chamber to fluctuate up and down through the tympanic membrane. The pulsating fluid force keeps the ore particles loose during the sorting process, effectively removing impurities from the particle clusters and significantly improving the concentrate grade.

TECHNICAL PARAMETERS

| Model | GTLH500T | GTLH750T | GTLH1000T | GTLH1250T | GTLH1500T | GTLH1750T | GTLH2000T | GTLH2500T | GTLH3000T | GTLH3500T | GTLH4000T | GTLH4500T | GTLH5000T | |

| Rated background magnetic field (T) | 1T/1.4T/(1.8T) | |||||||||||||

| Medium induced magnetic field | 1.5T/2.1T/(2.7T) Constant current continuously adjustable | |||||||||||||

| Coil cooling method | Oil-water compound cooling | |||||||||||||

| Rated excitation power (kw) | 22/35/55 | 24/38/60 | 26/40/70 | 28/42/95 | 32/45/102 | 37/55/110 | 45/65/120 | 60/76/140 | 72/106/180 | 93/130/200 | 102/140/220 | 110/145/240 | 120/155/270 | |

| Dry ore treatment capacity (t/h) | 0.06~0.5 | 0.5~1.2 | 4~7 | 10~20 | 20~30 | 30~50 | 50~80 | 80~120 | 120~180 | 180~270 | 300~450 | 450~600 | 500~700 | |

| Pulp passing capacity (m³/h) | 0.25~1.2 | 1~3 | 12.5~20 | 20~50 | 50~100 | 75~150 | 100~200 | 200~400 | 350~650 | 550~1000 | 750~1400 | 1100~1700 | 1400~2000 | |

| Exciter current (A) | 55/95/137 | 60/100/150 | 65/110/160 | 85/125/170 | 110/140/180 | 130/150/190 | 140/180/260 | 165/206/280 | 185/250/350 | 205/330/400 | 256/345/450 | 262/353/480 | 270/360/540 | |

| Concentration of ore feed (%) | 10~35% | |||||||||||||

| Feed grain size | -1 | -1.2 | ||||||||||||

| Rotary speed (r/min) | 1~4 (variable frequency adjustable) | |||||||||||||

| Outer diameter of swivel (mm) | φ500 | φ750 | φ1000 | φ1250 | φ1500 | φ1750 | φ2000 | φ2500 | φ3000 | φ3500 | φ4000 | φ4500 | φ5000 | |

| Power of swivel motor (kw) | 0.18 | 0.75 | 1.1 | 1.5 | 3 | 4 | 5.5 | 11 | 18.5 | 30 | 37 | 45 | 55 | |

| Oil pump power (kw) | 4kw | 5.5kw | ||||||||||||

| Pulsating motor power (kw) | 0.55 | 1.5 | 2.2 | 3 | 4 | 4 | 7.5 | 11 | 18.5 | 30 | 37 | 45 | 55 | |

| Pulsation stroke (mm) | 0-30 (mechanically adjustable) | |||||||||||||

| Pulsation stroke (times/min) | 0-300 (variable frequency adjustable) | |||||||||||||

| Exciter voltage (DCV) | 0-512 (varies with current) | |||||||||||||

| Ore unloading water pressure (Mpa) | 0.2~0.4 | |||||||||||||

| Water consumption for unloading (m³/h) | 0.65~1.4 | 1.4~2.5 | 8~12 | 12~20 | 20~30 | 30~50 | 50~100 | 100~150 | 150~200 | 250~350 | 350~500 | 500~650 | 550~800 | |

| Larger part weight (t) | 2/3.2/4.5 | 2.5/3.2/4 | 3/4.2/5 | 4/6/6.8 | 6.5/12/15 | 8.5/15/17 | 20/24/28 | 24/26/28 | 33/36/39 | 50/52/55 | 68/75/85 | 70/78/82 | 78/80/85 | |

| Overall dimension (mm) | Long | 1650 | 2000 | 2650 | 2880 | 3430 | 3320 | 4200 | 3660 | 4410 | 4900 | 5470 | 5980 | 7000 |

| 1800 | 2600 | 2850 | 3420 | 3600 | 3980 | 4350 | 5100 | 5030 | 6490 | 6200 | 6160 | 7500 | ||

| 1950 | 2900 | 2520 | 3580 | 3750 | 4120 | 4650 | 5400 | 5590 | 7000 | 6930 | 6270 | 8000 | ||

| Wide | 1500 | 2270 | 2350 | 2900 | 3680 | 3800 | 4690 | 4690 | 5540 | 5500 | 6240 | 6630 | 8100 | |

| 1800 | 2860 | 3000 | 3280 | 3850 | 4260 | 4870 | 5930 | 5650 | 7000 | 7500 | 7830 | 8300 | ||

| 2000 | 3200 | 3600 | 3650 | 4350 | 4770 | 4950 | 5520 | 5780 | 8200 | 8760 | 7210 | 8600 | ||

| High | 1250 | 2100 | 2450 | 2860 | 3410 | 3800 | 4150 | 5290 | 6450 | 6950 | 8400 | 9200 | 9400 | |

| 1320 | 2400 | 2630 | 3000 | 3650 | 4130 | 4300 | 5450 | 6500 | 7400 | 8600 | 9480 | 9650 | ||

| 1550 | 2600 | 2490 | 3300 | 3800 | 4300 | 4510 | 5760 | 6550 | 7950 | 8900 | 9600 | 9800 | ||

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE