Heavy Vibrating Screen

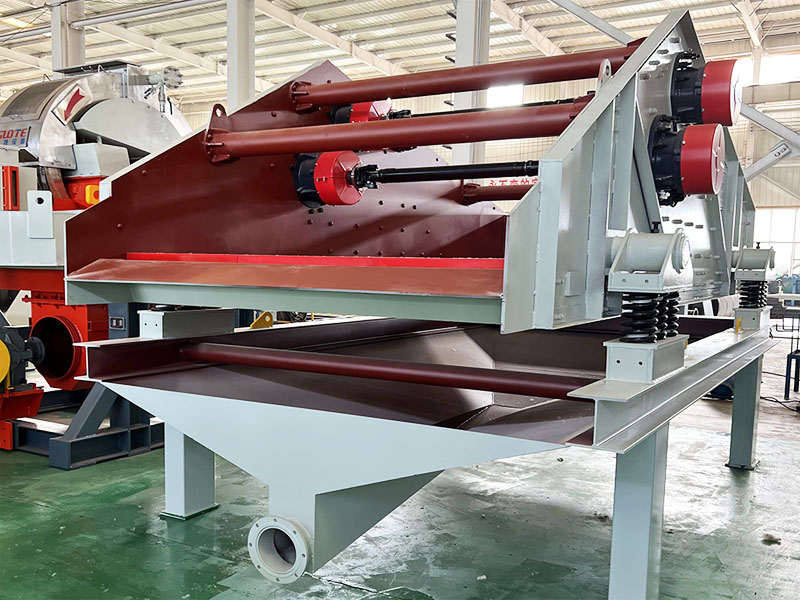

[Overview]:Heavy vibrating screen is a large-scale industrial equipment designed for high-intensity screening. The core components include screen box, screen mesh, vibration motor (or exciter), vibration reduction system (rubber spring) and chassis. Its side panels are made of high-quality steel plates and connected by high-strength bolts or rivets to ensure a stable and durable structure. The equipment uses the exciting force generated by the vibration motor to drive the screen body to move. It is suitable for screening large particles and high-density materials, and the maximum feed particle size can reach 350mm.

[Application scenarios]:It is widely used in mining (ore pre-screening), coal (coal preparation and de-intermediation), metallurgy (blast furnace trough, coking plant), building materials and power industries, etc. It can adapt to the harsh environment of high impact load for the classification of larger block materials and medium and small granular materials.

ADVANTAGES

1. High efficiency and energy saving: sub-resonance design reduces energy consumption by 30%, and the screening efficiency reaches more than 85%;

2. Structural optimization: modular screen replacement takes only 10 minutes, and the spring steel screen is resistant to blockage and has a long service life;

3. Easy maintenance: thin oil lubrication of the exciter reduces failures, and rubber spring vibration isolation reduces noise;

4. Reasonable design: flexible connections such as cross-axis universal joint drive shaft or rubber coupling are used for stable operation.

5. Adjustable frequency: the exciting force can be randomly adjusted, which is convenient for modular design and use.

|

|

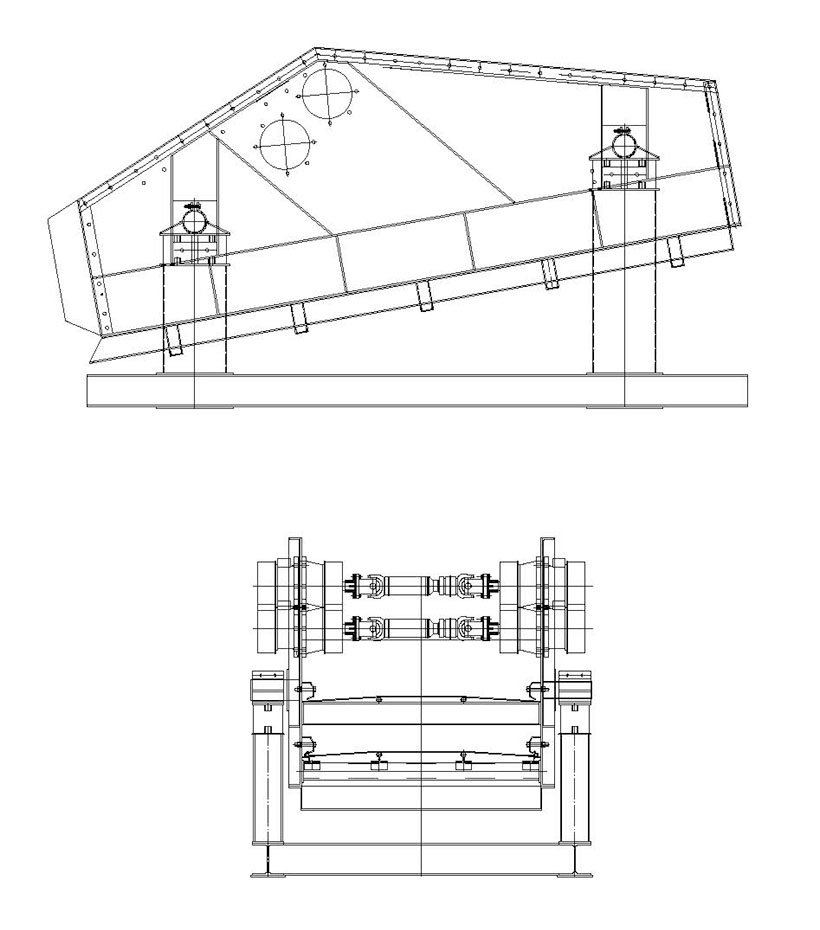

PRODUCT STRUCTURE

Introduction: The equipment works based on the principle of self-synchronous vibration: the dual motors rotate in opposite directions to generate a combined force, so that the screen box vibrates periodically in a straight line direction, and the material moves parabolically on the screen surface, achieving efficient stratification and screening. The screen adopts a small piece assembly design for easy replacement; the amplitude can be flexibly controlled by adjusting the angle of the eccentric block. The typical processing capacity is 100-800t/h, and 2-3 layers of screens can be customized to meet multi-level grading needs.

Working principle: The vibrator is installed on the side plate of the screen box and is driven by the motor through the coupling to generate centrifugal inertia force, forcing the screen box to vibrate. The adjustment of the screen surface inclination can be achieved by changing the position height of the spring support. The screen plate has perforated screens and rubber screen plates, which are single-layer and double-layer. All types of screen plates can meet the requirements of high screening efficiency, long life, and no hole blocking. The material is evenly put into the screen box from the feed inlet, thrown forward and loosely layered under the action of vibration: the lower screen screens small particles, and the upper screen retains large particles side by side to the discharge end. The whole process is through high-frequency vibration to prevent hole blocking, and the material is output according to particle size classification after screening.

TECHNICAL PARAMETERS

| Model | Feed size (mm) | Processing capacity (t/h) | Sieve plate specifications (mm) | Sieve plate area (m²) | Power (kw) |

| GTYX-1530 | ≤5 | 20-30 | 1500*3000 | 4.5 | 3X2 |

| GTYX-1840 | ≤5 | 30-50 | 1800*4000 | 7.2 | 3.7X2 |

| GTYX-2140 | ≤5 | 60-100 | 2100*4000 | 8.4 | 5.5X2 |

| GTYX-2440 | ≤5 | 100-150 | 2400*4000 | 9.6 | 7.5X2 |

| GTYX-3050 | ≤5 | 100-200 | 3000*5000 | 15 | 7.5X4 |

| GTYX-3060 | ≤5 | 150-250 | 3000*6000 | 18 | 7.5X4 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE