GTCK Magnetic Iron Separator for Magnetite ore

[Overview]:GTCK magnetic ore iron removal system is an automated sorting equipment designed for the problem of mixed ferromagnetic impurities in magnetic ores. Its core is to optimize the magnetic circuit and multi-stage sorting technology through computer, while efficiently adsorbing iron parts (such as bolts, tool remnants, etc.), significantly reducing the amount of magnetic ore entrainment (ore amount ≤ 5%), thereby avoiding damage to downstream equipment such as crushers and conveyor belts caused by iron parts.

[Application scenarios]:Widely used in iron ore mining, metallurgical sintering plants, building materials (such as cement raw material lines) and port ore transfer systems. Applicable to the ore processing process containing strong magnetic substances, including: raw ore primary crushing section, sintering and pelletizing production line, lump ore transfer node, etc.

ADVANTAGES

1. High efficiency of sorting: automatic unloading of iron, multi-stage magnetic separation (≥4 times sorting) combined with waist drum design, iron removal rate >95%, ore content <5%;

2. Energy-saving and reliable: using intermittent excitation technology, energy consumption is reduced by 30~50% (average power ≤10.6kW), supporting 7×24 hours of automatic continuous operation;

3. Environmental adaptability: fully sealed bearing seat + automatic deviation correction structure, tolerant to high dust and humid environment, maintenance cycle extended by 3 times;

4. Intelligent collaboration: linked with metal detector to realize trigger-type iron removal, supporting manual/centralized control dual-mode operation.

|

|

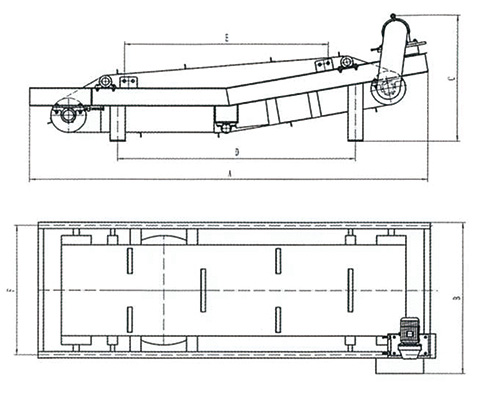

PRODUCT STRUCTURE

Introduction: GTCK Magnetic Iron Separator for Magnetite ore is mainly suitable for iron removal on conveying belts of magnetic materials such as raw ore, sintered ore, pelletized ore, lump ore, etc. It relies on special magnetic circuit design to separate the selected materials multiple times, so as to absorb ferromagnetic debris from magnetic ore with the least amount of ore replacement. GTCK magnetic ore iron removal system is based on multi-stage magnetic separation technology and intelligent linkage control, which solves the industry problem of high ore content when removing iron from magnetic ores. Its high adaptability (fully sealed structure, wide bandwidth coverage) and low energy consumption characteristics (intermittent excitation) are especially suitable for heavy industrial scenes with continuous operation, and are key equipment to ensure the safe operation of mine crushing systems. It is mainly composed of four core components: 1. Metal detector. 2. Belt electromagnetic iron remover. 3. Non-magnetic material separation platform. 4. Rectification control cabinet.

Working principle: 1. Iron detection: When the metal detector detects the signal of iron, it transmits the signal to the automatic electric control cabinet; 2. Instant excitation adsorption: The electric control cabinet starts the belt of the belt type iron remover in time and starts the excitation accurately. When the iron reaches the main magnetic pole, it uses instant strong excitation to simultaneously absorb the surface or deep iron and some magnetic materials; 3. Multi-stage magnetic separation: After the iron is absorbed, it immediately switches to the excitation state, and no longer continues to absorb the material, reducing the amount of material taken out; the absorbed iron together with the magnetic material is driven by the iron remover belt to move backwards, and the first magnetic separation is carried out. In the first separation, large pieces of magnetic materials fall back onto the conveyor belt; the material continues to run with the belt to the magnetic separation area with a special magnetic field arrangement, and then after multiple separations in the separation area, most of the magnetic materials fall back onto the conveyor belt; 4. Final separation on non-magnetic platform: The remaining small amount of materials and iron parts are brought to the non-magnetic separation platform for the final separation, and the iron parts are discharged separately to complete the iron removal; the excitation of the main engine of the GTCK iron removal system is completely stopped, and the iron remover belt is delayed to stop and wait for the next signal.

TECHNICAL PARAMETERS

| Model | Belt Width(mm) | Average Power(kw) | Main Excitation Power(≤kw) | Auxliary Excitation Power(≤kw) | lron-charging Belt width(mm) | Driving Power(kw) | Matched Metal Detector Model | Overall Dimension(mm) | Weight(kg) |

| GTCK-6 | 650 | ≤2 | 5 | 4.8 | 500 | 3.0 | GJT-F-6 | 3150*1050*980*1800*1700*858 | 1450 |

| GTCK-8 | 800 | ≤3 | 9 | 7.5 | 650 | 4.0 | GJT-F-8 | 3500*1220*1180*2000*1600*988 | 2100 |

| GTCK-10 | 1000 | ≤4.6 | 13 | 10.8 | 800 | 5.5 | GJT-F-10 | 3750*1380*1280*2100*1750*1196 | 2920 |

| GTCK-12 | 1200 | ≤5 | 18 | 15 | 1000 | 5.5 | GJT-F-12 | 4240*1660*1370*2530*2165*1418 | 3900 |

| GTCK-14 | 1400 | ≤6.5 | 25 | 18 | 1200 | 7.5 | GJT-F-14 | 4450*1750*1500*2800*2450*1520 | 5150 |

| GTCK-16 | 1600 | ≤8 | 32 | 27 | 1400 | 11 | GJT-F-16 | 4650*2000*1600*3150*2600*1755 | 5900 |

| GTCK-18 | 1800 | ≤9.5 | 45 | 36 | 1600 | 15 | GJT-F-18 | 4920*2180*1750*3450*2850*1950 | 8700 |

| GTCK-20 | 2000 | ≤10.6 | 50 | 42 | 1800 | 15 | GJT-F-20 | 5100*2360*1800*3620*3200*2150 | 11500 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE