Electromagnetic Slurry Magnetic Separator

[Overview]:Electromagnetic slurry magnetic separator is a key equipment that uses controllable electromagnetic field to separate magnetic minerals from ore pulp. Its core lies in generating a strong and adjustable magnetic field through the excitation coil, which can reach up to 2.2T. It is widely used in ore dressing plants to process fine-grained or weakly magnetic ores.

[Scope of application]:Electromagnetic separator for slurry is suitable for efficient iron removal and purification of fine-grained non-metallic ores such as feldspar, quartz sand, nepheline, fluorite, kyanite, kaolin, talc, bentonite, etc. It can also be used for other rare earth minerals such as hematite, wolframite, manganese ore, etc. It can be used in conjunction with a vertical ring high gradient magnetic separator to form an efficient and reliable magnetic separation and purification process to meet the needs of refined deep processing of different minerals.

ADVANTAGES

Electromagnetic slurry magnetic separator,Electromagnetic separator for slurry,Magnetic slurry high gradient magnetic separator,High Gradient Slurry Electromagnetic Separator,High Extraction Magnetic Filter.

◆Unique electromagnetic coil design and efficient cooling method.

The excitation coil of the electromagnetic slurry high gradient magnetic separator is cooled by fully sealed cooling oil. The external high-efficiency heat exchanger performs oil-water heat exchange to achieve oil-water composite cooling, fast cooling speed, low temperature rise, and stable magnetic field.

◆The sorting medium produces an extremely high magnetic field gradient, and the sorting effect is better.

The medium is made of special magnetic conductive stainless steel, which can produce an extremely high gradient magnetic field under the excitation of the background magnetic field. It has a strong adsorption effect on low-content weak magnetic ore, and the sorting effect is better.

◆Fully automatic operation, low operation and maintenance costs.

The working process of the equipment is controlled by an automated program, which can realize unattended fully automatic operation, reducing operation and maintenance costs.

◆High-pressure water forward and reverse flushing, clean sorting, and no residue.

When the equipment is running, high-pressure water is used to clean the medium. The cleaning time can be set according to different minerals and different stages of sorting to improve processing efficiency.

|

|

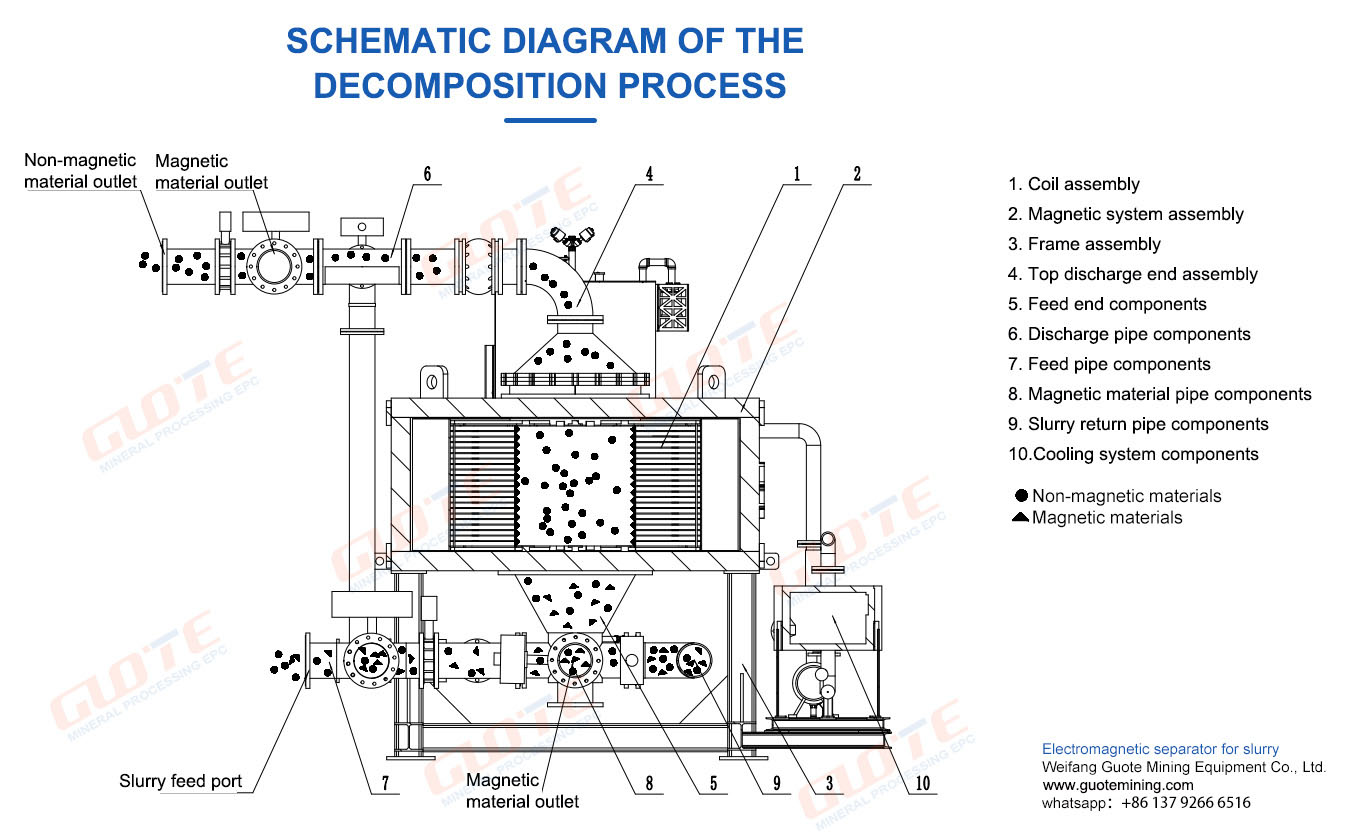

PRODUCT STRUCTURE

Introduction: Electromagnetic slurry magnetic separator is the latest magnetic separation product developed by Guote Mining Equipment. Its background magnetic field can reach up to 2.2 Tesla, with a large magnetic field gradient, and a variety of special magnetic conductive stainless steel media are available to meet the beneficiation needs of different regions and different types of minerals.

Working process: In the early stage of beneficiation, the excitation coil is energized with direct current to form an induction magnetic field of up to 22000GS on the surface of the magnetic medium in the separation area. The slurry containing impurities is quantitatively fed into the lower magnetic yoke through the bottom feed pipe by a slurry pump equipped with a variable frequency speed regulating motor. After the slurry is evenly dispersed, it enters the magnetic medium separation area through the pores of the lower magnetic yoke. The magnetic particles in the slurry are firmly adsorbed on the surface of the magnetic medium, and the non-magnetic particles pass through the magnetic medium and are discharged from the mine mouth through the pores of the upper magnetic yoke. After the beneficiation process has been running for a period of time, a large number of magnetic particles are adsorbed on the magnetic medium, and the control system automatically enters the return ore process. When the excitation coil is continuously energized, the feed valve is first closed, and then the return valve is opened. At this time, the slurry remaining in the cavity flows back to the original ore pool. After the slurry in the chamber is completely emptied, the return valve is closed and the control system automatically enters the flushing process. First, the excitation coil is powered off, the magnetic medium loses its magnetic field, and the adsorption force on the magnetic particles disappears. Then the tailings valve and the flushing valve are opened in turn, and the magnetic medium is repeatedly flushed with positive and negative high-pressure flushing water and pulse high-pressure gas, so that the magnetic particles adsorbed on the magnetic medium are thoroughly flushed off and discharged into the magnetic particle tank. When the magnetic medium is flushed, the flushing valve and the tailings valve are closed in turn, and the flushing process ends. The control system automatically starts the magnetic particle sorting process, and then the equipment starts a new round of process cycle.

TECHNICAL PARAMETERS

| Model | GTDZ-520F | GTDZ-780F | GTDZ-1000F | GTDZ-1200F | GTDZ-1500F | GTDZ-1750F | GTDZ-2000F | GTDZ-2500F |

| Magnetic field strength (T) | 1.0/1.4/1.7/2.0/2.2 | |||||||

| Input voltage (ACV) | 380 | |||||||

| Excitation current (DCV) | ≤180/220/260 | ≤220/260/310 | ≤250/300/360 | ≤280/340/410 | ≤320/380/480 | ≤350/420/540 | ≤400/460/600 | ≤500/550/660 |

| Rated excitation power (KW) | ≤80/100/120 | ≤105/115/140 | ≤115/135/165 | ≤130/150/185 | ≤150/170/220 | ≤160/190/245 | ≤180/210/270 | ≤245/250/600 |

| Cooling method | Oil-water composite | |||||||

| Magnetic cavity diameter (mm) | 520 | 780 | 1000 | 1200 | 1500 | 1750 | 2000 | 2500 |

| Processing capacity (m³/h) | 15~25 | 30~40 | 50~70 | 70~90 | 90~140 | 100~160 | 120~200 | 170~280 |

| Inlet pulp concentration (%) | 15~30 | |||||||

| Material particle size (mesh) | -24~200 | |||||||

| Overall dimensions (mm) L*W*H | 3000*2840*3150 | 3290*3200*3580 | 3350*3340*3680 | 4000*3940*3850 | 4830*4170*4780 | 5680*4830*5980 | 4710*4520*5350 | 7400*6000*8630 |

RELATED PRODUCTS

RELATED NEWS

- Weifang Guote Mining Equipment Co., Ltd.

- Repair and maintenance of mining machinery and equipment.

- 2024 Guote Mining Equipment Promotional Film

- Process characteristics and process of quartz stone pickling

- What is a magnetic separator? What types of magnetic separators are there?

- 2024 Vietnam International Mining and Mineral Resources Recycling Exhibition

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE