Electromagnetic Powder Magnetic Separator

[Overview]: The powder magnetic separator is a magnetic separation device specially used for dry powder materials. It can efficiently separate magnetic substances in powders through controllable electromagnetic fields. When it is working, the dry powder evenly passes through the high-intensity magnetic field area generated by the electromagnetic system. The magnetic particles are adsorbed to the surface of the magnetic field by the magnetic force, and the non-magnetic powder falls freely or is discharged with the airflow; the adsorbed magnetic substances automatically fall off and are collected after leaving the magnetic field.

[Scope of application]: Dry powder magnetic separator is suitable for dry iron removal and purification of non-metallic minerals such as quartz, feldspar, nepheline, kaolin and fluorite. It is also widely used in chemical, plastic, pharmaceutical and other industries.

ADVANTAGES

Electromagnetic dry powder magnetic separator,Powder magnetic separator,Dry powder magnetic separator,Electromagnetic separator for powder.

1. Remove fine crops that are not easy to circulate. Under the action of the vibration motor, raw materials with a volume of less than 200 microns or high humidity can pass through the screen consistently.

2. Processing of high-temperature materials. The standard model can handle raw materials with a temperature of up to 70 degrees Celsius, while the special model can be used to handle raw materials with higher temperatures.

3. Simple installation. As long as the bracket is safe and correct, the equipment can be installed arbitrarily.

4. The magnetic filter screen is easy to clean. Place a tray at the outlet of the material to recover the separated material, and turn off the power to demagnetize the screen to facilitate cleaning.

5. Completely separate magnetic materials from basic materials. Basic materials will never enter the separation box.

|

|

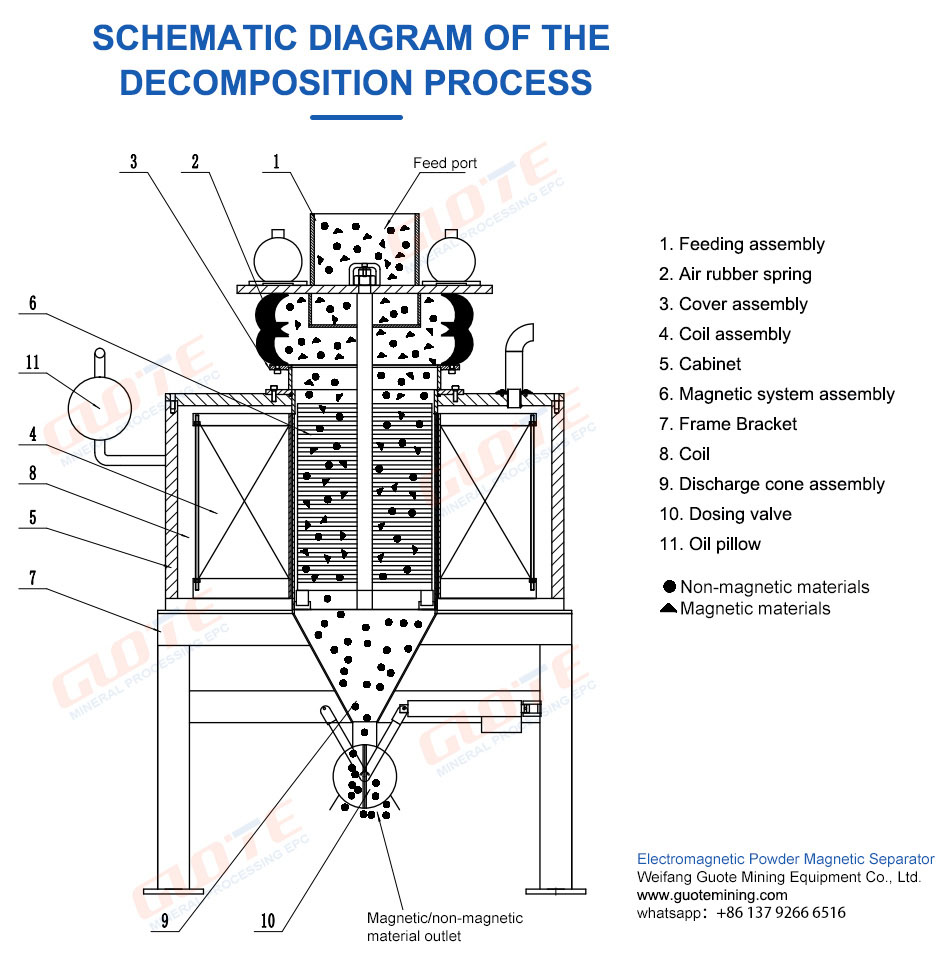

PRODUCT STRUCTURE

Introduction:Electromagnetic dry powder magnetic separator is particularly suitable for sorting fine-grained mineral powder particles, such as the removal of iron and titanium impurities in non-metallic feldspar powder, quartz powder, kaolin powder and other minerals, as well as the removal and purification of powder materials such as ceramics, chemicals, medicines, electronics, positive and negative electrode materials, graphite, and white carbon black. The equipment has the characteristics of waterless operation, zero pollution, micron-level impurity removal accuracy, and intelligent adjustable magnetic field strength.

Workflow Introduction:1. Material feeding: Dry powder materials are fed into the feed port of the magnetic separator evenly and stably through feeding equipment such as vibrating feeders or belt conveyors, and enter the sorting area in an orderly manner. For example, when processing ceramic raw materials, a vibrating feeder is used to feed the dry powder raw materials into the magnetic separator at a uniform speed. 2. Magnetic field establishment: The electromagnetic coil is connected to the current to generate a strong electromagnetic field with adjustable strength as needed. The magnetic field is the key to separating magnetic and non-magnetic materials. When processing ores with different magnetic strengths, the magnetic field strength needs to be adjusted to adapt. 3. Sorting process: When the material enters the sorting area, the magnetic minerals are attracted by the magnetic field force, move in the direction of the magnetic field and adhere to magnetic media such as magnetic rollers and magnetic plates; non-magnetic minerals are not affected or are affected by very little magnetic force, and rely on mechanical forces such as gravity and inertia to continue moving along the original path. For example, when processing alumina powder containing iron impurities, the iron impurities are adsorbed as magnetic substances, and the alumina continues to move forward. 4. Non-magnetic material discharge: non-magnetic materials are discharged from the special non-magnetic material outlet of the magnetic separator. 5. Magnetic material collection: magnetic materials adsorbed on the magnetic medium leave the magnetic field area as the magnetic medium rotates or moves, and fall off due to the loss of magnetic force, and are discharged from the magnetic material outlet to complete the separation. 6. Circular operation: the magnetic medium continues to work in the separation area. After completing the sorting of one batch of materials, the next batch is processed immediately to achieve continuous and uninterrupted magnetic separation operation.

TECHNICAL PARAMETERS

| Model | Standard | High magnetic type | ||||

| GDF-150 | GDF-250 | GDF-300 | GDF-150H | GDF-250H | GDF-300H | |

| Capacity(t/h) | 5 | 15 | 20 | 5 | 15 | 20 |

| Weight(kg) | 200 | 400 | 450 | 800 | 1200 | 1400 |

| Filter Net Outer Diameter (mm) | 145 | 245 | 295 | 145 | 245 | 295 |

| Filter Net Sheet Number | 33 | 35 | 35 | 33 | 35 | 35 |

| Insulation Oil Amount (L) | 18 | 50 | 50 | 60 | 70 | 70 |

| Control Panel Size (mm) | 300x400x540 | 350x500x600 | ||||

RELATED PRODUCTS

RELATED NEWS

- Weifang Guote Mining Equipment Co., Ltd.

- Repair and maintenance of mining machinery and equipment.

- 2024 Guote Mining Equipment Promotional Film

- Process characteristics and process of quartz stone pickling

- What is a magnetic separator? What types of magnetic separators are there?

- 2024 Vietnam International Mining and Mineral Resources Recycling Exhibition

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE