Dry Drum Magnetic Separator

[Overview]:Dry drum magnetic separator is a device that uses a permanent magnetic drum to efficiently magnetically separate dry materials (water content <5%). Its core principle is to absorb magnetic minerals through the rotating drum, and non-magnetic materials fall off directly due to gravity, so as to separate magnetic materials from non-magnetic materials. This equipment does not require water and has low energy consumption. It is suitable for scenarios such as mine pre-selection, steel slag metal recovery and industrial raw material iron removal, especially for arid areas and solid waste resource utilization needs.

[Scope of application]: Strong magnetic minerals such as magnetite and ilmenite; weak magnetic minerals such as hematite and manganese ore; industrial solid wastes such as steel slag and fly ash; and non-metallic impurity removal such as quartz sand and ceramic raw materials.

ADVANTAGES

Dry drum magnetic separator,Drum dry magnetic separator,Rotary drum magnetic separator,Dry drum permanent magnetic separator,Permanent magnet dry drum magnetic separator.

1. Equipped with a vibrating feeder to feed evenly and remove debris continuously and automatically.

2. Rare earth permanent magnet material is used as a magnetic source, with a large magnetic penetration depth and strong suction.

3. The new type of compensating magnetic pole type magnetic system makes the magnetic field intensity higher and the gradient larger.

4. It can be made into a two-cylinder or multi-cylinder type, and the magnetic force can be selected (1000~10000Gs).

5. The whole machine is maintenance-free and safe and reliable to use.

|

|

|

|

|

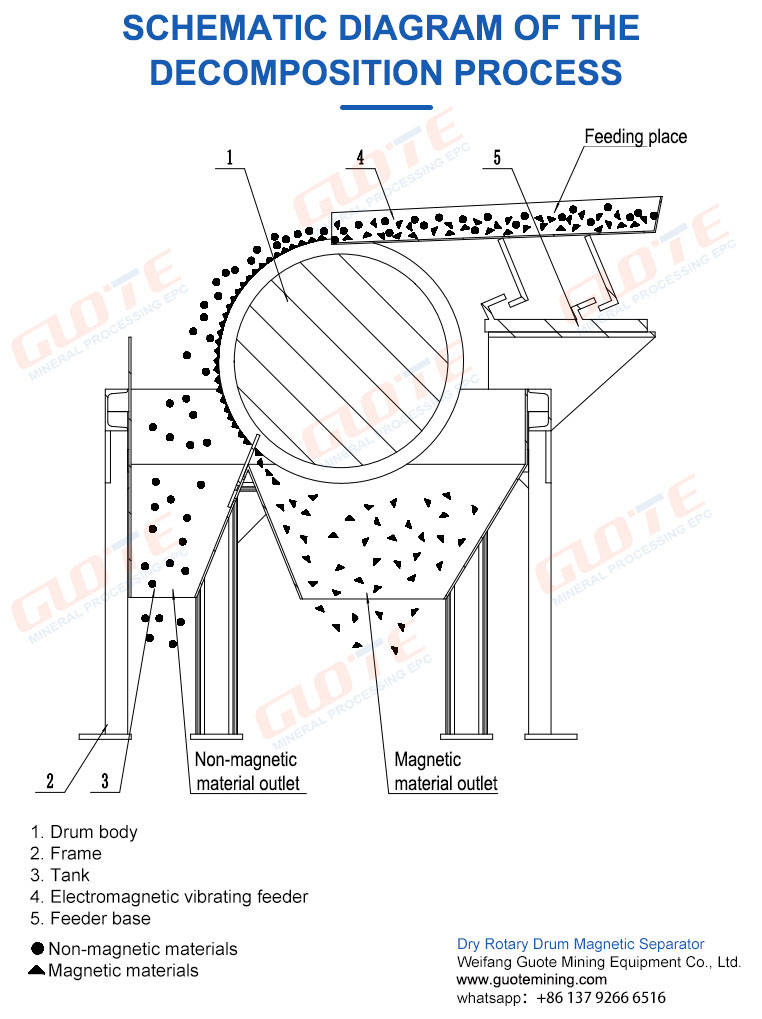

PRODUCT STRUCTURE

Introduction:Dry drum magnetic separatort can be used to remove iron pollutants from powdery or fine-grained materials, and is used for the purification of non-metallic minerals such as refractory materials, glass, ceramics, abrasives, etc., the removal of impurities in chemicals, grains and non-magnetic metal ores, and the dry pre-selection of hematite and limonite. Dry drum magnetic separator is the core magnetic separation equipment for mineral processing.

Working principle:The dry material (water content <5%) is evenly spread on the surface of the rotating drum through the vibrating feeder equipped with this magnetic separator. The magnetic minerals are attracted by the strong magnetic force and fall off due to gravity after the drum rotates to the non-magnetic area; the non-magnetic materials are not affected by the magnetic force and fall directly into the non-magnetic material trough. The magnetic system adopts the design of alternating N/S pole arrangement, so that the material rolls on the drum surface to peel off the inclusions, realizing the efficient separation of magnetic and non-magnetic materials. No water source is required in the whole process, which is one of the core equipment of the mineral processing production line.

TECHNICAL PARAMETERS

| Model | Overall dimensions (mm) | Roller length (mm) | Roller diameter (mm) | Magnetic induction intensity (GS) | Number of rollers (pcs) | Drum speed (r/min) | Producti-vity (t/h) | Material size (mm) | Motor power (kw) |

| GCXII-120-Ⅰ | 2006x1100x1450 | 1200 | 600 | 1000-10000 | 1 | 17-82 | ≤5 | ≤10 | 3 |

| GCXII-120-Ⅱ | 2274x1700x2250 | 1200 | 600 | 1000-10000 | 2 | 17-82 | ≤6 | ≤10 | 5.5 |

| GCXII-120-Ⅲ | 2880x1700x2950 | 1200 | 600 | 1000-10000 | 3 | 17-82 | ≤8 | ≤10 | 3*3 |

| GCXII-140-Ⅰ | 2206x1100x1450 | 1400 | 608 | 1000-10000 | 1 | 17-82 | ≤6 | ≤10 | 4 |

| GCXII-140-Ⅱ | 2274x2000x2250 | 1400 | 608 | 1000-10000 | 2 | 17-82 | ≤8 | ≤10 | 7.5 |

| GCXII-140-Ⅲ | 2800x2000x2850 | 1400 | 608 | 1000-10000 | 3 | 17-82 | ≤10 | ≤10 | 4*3 |

| GCXII-160-Ⅰ | 1960x1274x1650 | 1600 | 800 | 1000-10000 | 1 | 17-82 | ≤10 | ≤12 | 5.5 |

| GCXII-160-Ⅱ | 2674x2160x2850 | 1600 | 800 | 1000-10000 | 2 | 17-82 | ≤12 | ≤12 | 5.5*2 |

| GCXII-160-Ⅲ | 3120x2160x3700 | 1600 | 800 | 1000-10000 | 3 | 17-82 | ≤15 | ≤15 | 5.5*3 |

RELATED PRODUCTS

RELATED NEWS

- Weifang Guote Mining Equipment Co., Ltd.

- Repair and maintenance of mining machinery and equipment.

- 2024 Guote Mining Equipment Promotional Film

- Process characteristics and process of quartz stone pickling

- What is a magnetic separator? What types of magnetic separators are there?

- 2024 Vietnam International Mining and Mineral Resources Recycling Exhibition

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE