GTZ Dry Magnetic Pulley For Conveyor Belt

[Overview]:The conveyor belt magnetic pulley (magnetic roller) is a permanent magnet driven, efficient iron removal device. It is composed of a multi-pole magnetic system composed of rare earth permanent magnetic materials (such as neodymium iron boron) and is directly integrated into the conveyor belt drive roller position. Through the dynamic rotating magnetic field, it can continuously adsorb ferromagnetic impurities (such as iron filings, bolts, broken steel pieces, etc.) in bulk materials to improve the purity of raw materials and protect downstream equipment.

[Application scenarios]:Widely used in mining, energy, food processing, recycling and building materials industries. Suitable for impurity sorting of weakly magnetic or non-magnetic materials, typical scenarios include: mineral processing; coal purification; renewable resources; food security; building materials production.

ADVANTAGES

1. Zero-energy operation: permanent magnets do not require electricity, and there is no excitation cost for life;

2. Continuous and efficient iron removal: rotating adsorption synchronizes material movement, and the impurity removal rate is >98%;

3. Maintenance-free design: fully sealed and corrosion-resistant structure, no risk of coil burning;

4. Space saving: directly replaces traditional transmission rollers, saving installation space >50%;

5. Strong magnetic penetration: surface magnetic field ≥5000 Gauss (0.5T), effective action depth up to 200mm.

|

|

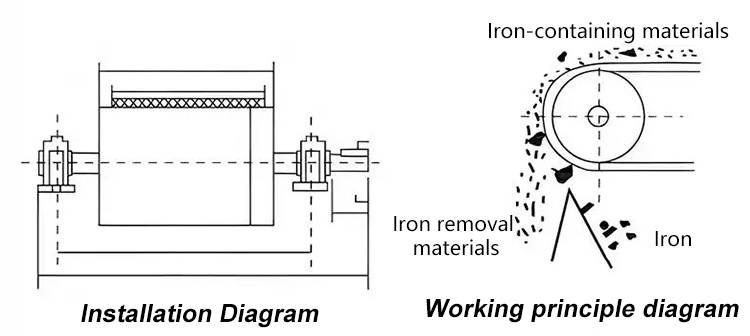

PRODUCT STRUCTURE

Introduction: The conveyor belt magnetic pulley (magnetic roller) takes permanent magnet energy saving, dynamic adsorption, and structural integration as its core competitiveness, perfectly solving the pain points of traditional iron removal equipment with high energy consumption, space occupation, and frequent maintenance. It is especially suitable for bulk material processing scenarios with limited space and continuous operation, and is the preferred solution for industrial clean production and equipment protection. The magnetic roller is composed of three core components: 1. Permanent magnetic core: NdFeB magnetic blocks are arranged alternately in radial direction to form a high-intensity gradient magnetic field; 2. Stainless steel sheath: 304 stainless steel shell is wear-resistant and anti-sticky material to protect the life of the magnetic core; 3. Drive structure: integrated bearing seat and drive shaft, adapted to the standard conveyor belt power system.

Working principle: 1. Material passing: iron-containing impurities are evenly spread on the surface of the conveyor belt and pass over the strong magnetic roller; 2. Dynamic adsorption: When the magnetic roller rotates, the surface magnetic field is constantly flipped, and ferromagnetic impurities are strongly adsorbed to the roller surface; 3. Automatic impurity removal: impurities rotate with the magnetic roller to the non-working surface (the bottom material-free area), and fall off due to gravity or scraper peeling, realizing a self-cleaning cycle.

TECHNICAL PARAMETERS

| Model | Roller Diameter(mm) | Roller Lenght(mm) | Belt width(mm) | Surface Magnetic induction intensity(mT) | Feed-in Size(mm) | Processing Capacity(t/h) | Weight(t) |

| GTZ50/50 | 500 | 600 | 500 | 160-350 | ≤50 | 50-80 | 0.4 |

| GTZ50/65 | 500 | 750 | 650 | 160-350 | ≤50 | 60-110 | 0.5 |

| GTZ63/65 | 630 | 750 | 650 | 160-400 | ≤50 | 70-120 | 0.7 |

| GTZ63/80 | 632 | 950 | 800 | 180-500 | ≤150 | 100-160 | 0.9 |

| GTZ80/80 | 800 | 950 | 800 | 180-500 | ≤150 | 120-200 | 1.4 |

| GTZ63/100 | 630 | 1150 | 1000 | 180-500 | ≤150 | 130-180 | 1.5 |

| GTZ80/100 | 800 | 1150 | 1000 | 180-500 | ≤150 | 150-260 | 1.9 |

| GTZ100/100 | 100 | 1150 | 1000 | 180-500 | ≤250 | 180-300 | 2.6 |

| GTZ100/120 | 100 | 1400 | 1200 | 180-500 | ≤250 | 200-400 | 3.1 |

| GTZ120/140 | 120 | 1600 | 1400 | 180-500 | ≤250 | 250-460 | 4.6 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE