Dewatering Screen

[Overview]:Dewatering screen is a vibrating screening equipment dedicated to solid-liquid separation. Its core functions include dehydration, desludging and demediation, so it is also called sand and gravel dehydration screen, mining dehydration screen or tailings dehydration screen. It is designed for high-water-content materials (such as slurry, mud and sand). It accelerates water analysis through linear reciprocating vibration, significantly reduces the moisture content of materials, and achieves efficient dry discharge.

[Application scenarios]:It is widely used in raw coal dehydration, grading, desludging in coal preparation plants, mine screening, power plant screening, and material separation processes in new energy industries such as coal chemical industry. Such as: sand and gravel aggregate processing, coal preparation plant, ore dressing plant, environmental protection and chemical industry.

ADVANTAGES

1. High efficiency and energy saving: high-frequency vibration accelerates water separation, saving 30% electricity compared with traditional processes. Linear motion mode, materials are not easy to block the screen holes.

2. Durability and Low Consumption: The screen plates are made of polyurethane (with a wear resistance up to five times that of ordinary materials) for a long service life. The rubber spring design provides shock absorption, resulting in a noise level of ≤75dB.

3. Flexible Maintenance: The modular screen plates allow for quick replacement, and the vibrating motor is easily removable, minimizing downtime.

4. Highly Adaptable: The V-shaped screen deck and negative inclination (-5°) enhance dewatering, resulting in low water content, high efficiency, and high processing capacity for dry tailings discharge.

5. Lightweight and Durable: The riveted and welded steel components are superior to welded components for durability.

6. Technical Improvements: The use of corrugated screen plates significantly increases the dewatering area. The corrugated screen plates are also installed flat at the feed end, further increasing the equipment's processing capacity.

|

|

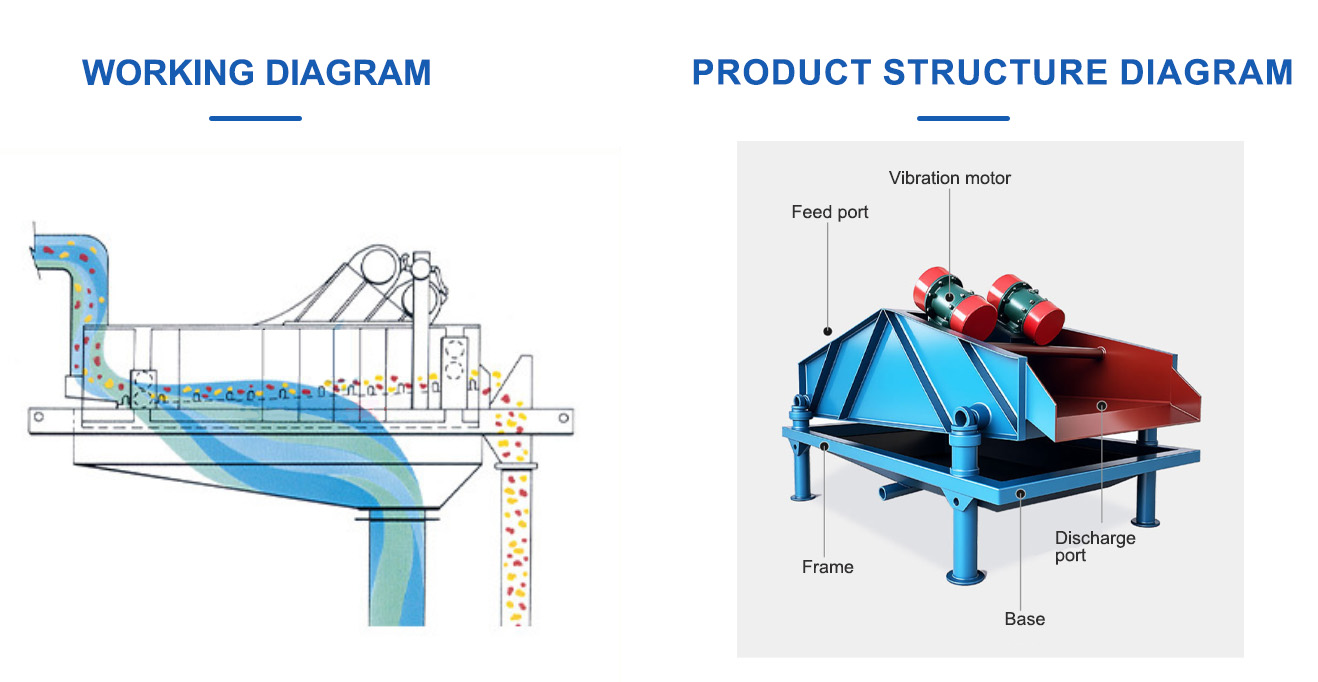

PRODUCT STRUCTURE

Introduction: The dewatering screen, with its efficient linear vibration and structural adaptability, is a core solid-liquid separation device. It is particularly suitable for dry tailings discharge and sand and gravel aggregate dewatering, achieving both environmental and economic benefits. The main body of the equipment consists of a screen box, a dual vibration motor (exciter), a rubber spring support system and a screen. The screen box is made of reinforced steel plate, and the screen can be selected from polyurethane slit type and stainless steel punching plate, which is suitable for automated production lines.

Working principle: Based on the synchronous reverse rotation of the dual motors, the centrifugal force generated by the eccentric block is superimposed in the vibration direction and offset in the opposite direction, driving the screen box to vibrate at high frequency in a straight line direction. The material movement is divided into two stages: 1. Rapid drainage, the 45° drainage screen plate at the feed end removes about 1/3 of the water; 2. Filter layer compaction: The material accumulates to form a filter layer, and high-frequency vibration makes it compacted. The surface water flows back and collects due to the negative inclination design of the screen surface, and finally the dry material is discharged in the form of filter cake.

TECHNICAL PARAMETERS

| Moedl | Screen surface angle (°) | Common sieve hole sizes (mm) | Feeding capacity (t/h) | Motor power (kw) | Reference total weight (t) |

| GTTS-1236 | -5~-3 | 0.1~0.5 | 18~65 | 2×2.2 | 4.5 |

| GTTS-1536 | -5~-3 | 30~90 | 2×2.4 | 5 | |

| GTTS-1838 | -5~-3 | 40~120 | 2×3.7 | 5.5 | |

| GTTS-2140 | -3~0 | 60~150 | 2×7.5 | 6.7 | |

| GTTS-2440 | -3~0 | 80~200 | 2×11 | 7 | |

| GTTS-2550 | -3~0 | 100~260 | 4×3.7 | 8.5 | |

| GTTS-3050 | -3~0 | 150~300 | 4×7.5 | 9.5 | |

| GTTS-3090 | -3~0 | 230~450 | 6×7.5 | 12 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE