Desludging Bucket

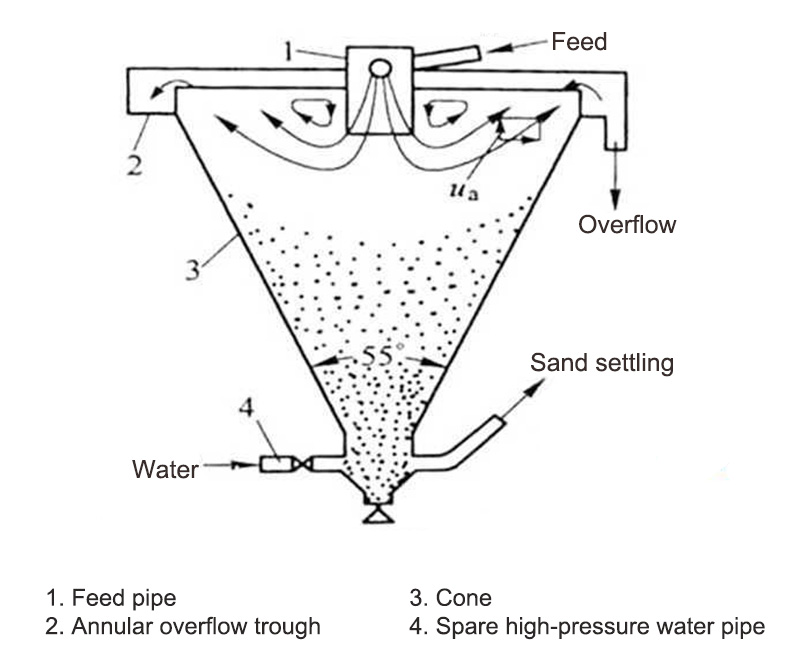

[Overview]:Desludging Bucket (also known as a desliming hopper or cone classifier) is a simple classification, desliming, and concentrating device based on the principle of gravity settling. Its core structure is an inverted cone with a central feed drum. Slurry is fed tangentially, where coarse particles settle to the bottom of the cone and are discharged, while fine particles are separated with the overflow. The device can achieve a particle size of less than 75μm. This device requires no power and relies on the slurry's natural flow to achieve solid-liquid separation, while also serving as an ore storage device. It is widely used for desliming and concentrating operations in mineral pretreatment.

[Application Scenarios]:Desliming hoppers are primarily used in pre-processing of minerals. Desliming non-metallic ores, such as quartz sand and phosphate rock, removes clay impurities (desliming rates of 33%-45%), improving subsequent separation efficiency. Pre-grinding concentration increases mill feed concentration and reduces energy consumption. Slime control regulates slurry concentration and ore yield to ensure stable operation of flotation or gravity separation equipment.

ADVANTAGES

1. Zero-energy operation: No motor is required, relying on slurry self-flow, making it suitable for environments with power shortages and offering extremely low O&M costs.

2. Simple and durable structure: The cone is welded from steel plates, eliminating complex transmission components, resulting in low failure rates and a long service life.

3. Space-efficient: The conical design provides a long settling path, achieving a processing capacity of 0.19–2.16 t/m2·h per unit area, while also providing ore storage.

4. Low-cost adaptability: Easy to manufacture and install, requiring low investment.

|

|

PRODUCT STRUCTURE

Introduction: The desludging hopper, with its gravity settling and conical structure, is a cost-effective desludging pretreatment device for mineral processing. It is particularly suitable for coarse desludging and concentration of non-metallic ores such as quartz sand. The main unit consists of an inverted conical shell, a central feed drum, an overflow chute, and a bottom grit outlet. Available materials include carbon steel with rubber lining or all-stainless steel, making it suitable for acidic slurry environments.

Working principle:1. Tangential Feed Buffering: The slurry enters the central cylinder tangentially, where the flow rate is reduced and buffered. 2. Radial Stratification: The slurry flows radially from the bottom of the cylinder toward the overflow weir. During this process, coarse particles with a settling velocity greater than the rising velocity sink to the bottom of the cone and are concentrated and discharged through the bottom grit trap. 3. Overflow Separation of Fine Mud: Fine particles flow with the surface liquid into the annular overflow trough and are discharged as tailings, achieving fine classification below 74μm.

TECHNICAL PARAMETERS

| Model | YX-1000 | YX-1500 | YX-2000 | YX-2500 | YX-3000 |

| Sedimentation area (㎡) | 0.78 | 2 | 3 | 4.9 | 7 |

| Volume (m³) | 0.27 | 0.83 | 2.27 | 4 | 7 |

| Discharge pipe diameter (mm) | 30 | 40 | 50 | 60 | 70 |

| Feed particle size (mm) | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| Processing capacity (t/㎡·d) | 4.5-52 | ||||

| Discharge concentration (%) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

| Desludging effect (%) | 33~45 | 33~45 | 33~45 | 33~45 | 33~45 |

| Weight (kg) | 500 | 980 | 1483 | 1850 | 2100 |

| Overall dimensions: diameter * height (mm) | 1264*1529 | 1804*2115 | 2404*2715 | 2906*3328 | 3406*3925 |

RELATED PRODUCTS

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE