MINERAL PROCESSING EQUIPMENT

-

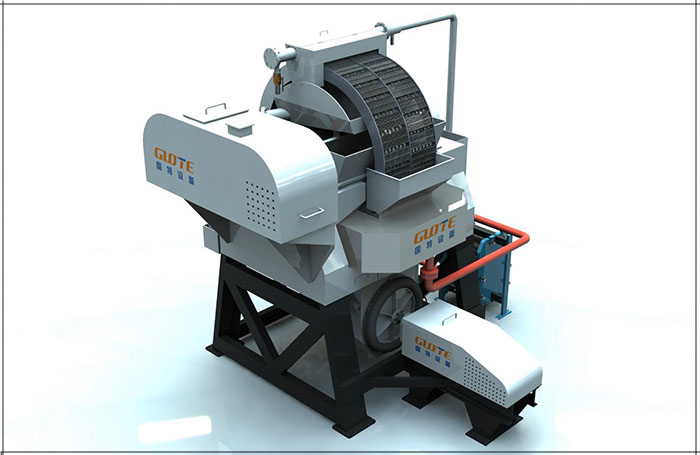

Electromagnetic slurry magnetic separator

2025年10月29日 Guote Views (489) +Read MoreThe GTDZ series electromagnetic slurry separator is a new type of electromagnetic slurry iron removal equipment designed and manufactured by Weifang Guote Mining Equipment Co., Ltd. It features high background magnetic field intensity, large magnetic field gradient, high iron removal efficiency, low clogging, reliable operation, easy operation and maintenance, and a high degree of automation.

This equipment is widely used for iron removal and purification of non-metallic minerals such as quartz, feldspar, kaolin, nepheline, fluorite, and talc with a mesh size of 40-400. It is particularly effective for purifying fine-grained non-metallic ores. A variety of custom magnetic stainless steel media options are available to meet the beneficiation requirements of different regions and mineral types.

Its main components include: steel frame, upper magnetic yoke, magnetic concentrator, lower magnetic yoke, separator outer cylinder, excitation coil mechanism, external iron yoke assembly, upper and lower piping systems, high-pressure water flushing device, oil-water composite cooling system, pneumatic device, and electrical control cabinet.

Advantages of this equipment: The GTDZ electromagnetic slurry magnetic separator’s excitation coil is made of high-quality conductive material and features a multi-layer winding structure, resulting in short excitation time and a large coil heat exchange area. Its fully sealed design allows the excitation coil to be completely immersed in cooling oil, cooled by the forced flow of cooling oil. The heated cooling oil is pumped by an oil pump to an external high-efficiency heat exchanger, where it is forced to exchange heat with water. This oil-water combined cooling system delivers rapid cooling, low coil temperature rise, and a stable magnetic field, allowing operation in warmer climates. The special stainless steel magnetic media generates an extremely high magnetic field of up to 1.6 Tesla, strongly adsorbing low-content, micronized, weakly magnetic impurities. It can remove iron from a variety of non-metallic minerals with particle sizes ranging from 40 to 400 mesh. High-pressure water, combined with pulsed high-pressure air, cleans the magnetic media in both forward and reverse directions, ensuring clean, residue-free removal and long-term clogging resistance. The control system of the GTDZ electromagnetic slurry separator utilizes internationally renowned electrical components, ensuring safety, reliability, easy maintenance, and stable performance. Operating parameters and process cycles can be pre-configured based on actual conditions, enabling unmanned, fully automated operation, reducing operating and maintenance costs. The system is also equipped with fault alarms for overcurrent and overheating, providing automatic shutdown protection in emergency situations.

Operating Process: At the start of the beneficiation process, a direct current is applied to the excitation coil, generating an induction magnetic field of up to 1.6T on the surface of the magnetic medium in the separation zone. Slurry containing magnetic impurities is fed into the lower magnetic yoke via a slurry pump equipped with a variable frequency motor. After being evenly dispersed, the slurry enters the magnetic medium separation zone through the pores of the lower yoke. Magnetic impurity particles in the slurry are firmly adsorbed on the surface of the magnetic medium, while non-magnetic concentrate particles pass through the medium and are discharged through the pores of the upper yoke from the concentrate outlet. After a period of operation, the magnetic medium has absorbed a large amount of magnetic impurities, at which point the control system automatically enters the recirculation process. With the excitation coil continuously energized, the feed valve is first closed, followed by the return valve. The slurry remaining in the chamber then flows back into the raw ore pool. Once the slurry in the chamber is completely discharged, the return valve is closed, and the control system automatically initiates the flushing process. First, the excitation coil is de-energized, depriving the magnetic field of the magnetic concentrator, which loses its attraction to magnetic impurity particles. The tailings valve and flushing valve are then opened, sequentially. High-pressure flushing water and pulsed high-pressure air are then used to repeatedly flush the magnetic concentrator, completely flushing any magnetic impurities adsorbed on the concentrator and discharging them through the tailings valve. Once the concentrator is completely flushed, the flushing and tailings valves are closed, completing the flushing process. The control system automatically initiates the impurity removal process, and the equipment begins a new process cycle.

-

Permanent Magnet Dry Roller Magnetic Separator

2025年10月29日 Guote Views (577) +Read MoreThe high-field-strength roller magnetic separator, developed and manufactured by Weifang Guote Mining Equipment Co., Ltd., is a high-gradient, high-field-strength magnetic separation device that can effectively remove weakly magnetic impurities from granular or coarse powder materials. This equipment is widely used in the purification of weakly magnetic impurities in industries such as ceramics, glass, refractory materials, abrasives, chemicals, food, and pharmaceuticals, as well as for the dry pre-selection of weakly magnetic ores such as hematite, limonite, and manganese ore.

Its main components include: a channel steel frame, magnetic rollers and drive rollers, magnetic roller mechanism belts, other stages of magnetic roller mechanisms, permanent magnet drums, various stages of material distribution adjustment plates, vibrating feeders, feed hoppers, equipment housing, observation windows, lower dust removal port, upper dust removal port, and various stages of power and transmission systems.

Product advantages: Utilizing a multi-stage composite magnetic separation structure of permanent magnet drums and permanent magnet rollers, it can effectively separate most magnetic particles from materials. The permanent magnet drums employ a new type of compensated magnetic pole magnetic system with a flipping mechanism, achieving a magnetic field strength of up to 8000 Gauss, resulting in greater magnetic field strength, stronger attraction, and a higher removal rate. The magnetic roller employs a composite magnetic system with a magnetic field strength of up to 18,000 Gauss. The conveyor belt used in the magnetic roller mechanism is made of a special material, offering excellent wear resistance and a long service life. A vibrating feeder ensures uniform and quantitative feeding of materials into the magnetic separator, guaranteeing a consistent material layer thickness and maximizing the separator’s functionality to improve separation efficiency. The power and transmission system utilizes a renowned brand of variable frequency speed-regulating motor, allowing real-time adjustment of the permanent magnet drum and magnetic roller mechanism’s speed according to material conditions. This adapts to and meets the particle size and output requirements of various materials. Dust collection ports located at the top and bottom of the equipment can be connected to dust collection equipment. Dust generated during mineral processing is contained within the casing and expelled from the equipment through negative pressure generated by the dust collector fan for centralized treatment, ensuring no dust pollution occurs during mineral processing.

Working Process: Granular material falls through a feed hopper into a vibrating feeder and is evenly vibrated and fed to the working area of the permanent magnet drum. Magnetic particles are firmly adsorbed to the drum’s surface and carried into a non-magnetic field zone, where they are discharged through the magnetic material outlet. Non-magnetic material, under the influence of gravity and inertia, falls onto the magnetic roller mechanism for the next stage of magnetic separation. A conveyor belt transports the material to the magnetic roller. In a magnetic field of up to 18,000 gauss, weakly magnetic particles are firmly adsorbed to the roller’s surface. The conveyor belt then carries the material to a non-magnetic field zone, where they are discharged through the magnetic material outlet. Non-magnetic material then enters the next stage of the magnetic roller mechanism. After multiple separations, non-magnetic particles are discharged through the non-magnetic material outlet at the front of the equipment.

-

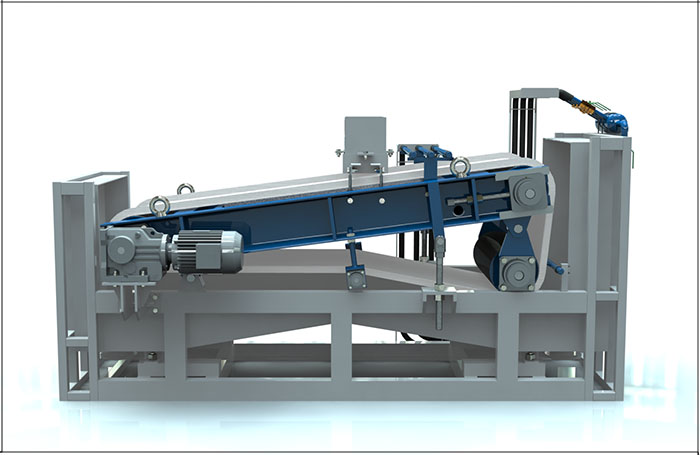

Permanent Magnet Wet Flat Plate Magnetic Separator

2025年8月20日 Guote Views (1324) +Read MoreThe GTGB permanent magnet high-field plate magnetic separator is a patented product developed and manufactured by Guote Mining Equipment. It features high-gradient, high-field strength magnetic separation. It integrates magnetic and gravity separation, enabling targeted separation of weakly magnetic minerals based on the ore’s distinct magnetic characteristics. It is widely used in the wet processing of non-metallic ores for iron removal and purification, and is particularly suitable for wet iron removal of non-metallic ores such as quartz sand and potassium-sodium feldspar. It also demonstrates excellent separation performance for weakly magnetic minerals such as hematite, limonite, specularite, siderite, manganese ore, and tantalum mud.

The GTGB permanent magnet high-field plate magnetic separator primarily consists of a channel steel frame, a lower trough, a magnetic support frame, a drive roller assembly, a plate magnetic system, a conveyor belt, a reduction motor, a feed box, and an automatic ore flushing device.

GTGB permanent magnet high field strength plate magnetic separator product advantages: (1) The magnetic system of this equipment is made of high-performance rare earth neodymium iron boron material, with a wide pole surface, a large number of magnetic poles, high magnetic induction intensity, and a large magnetic field gradient. The local maximum magnetic field can reach 15,000 gauss, which is close to the magnetic field strength of a high-gradient electromagnetic magnetic separator. (2) The magnetic system group adopts a flat plate arrangement structure, which has a larger magnetic field sweeping area than traditional magnetic separators and better iron separation effect. (3) The magnetic system mechanism and conveyor belt are both installed on an adjustable carrier. The horizontal angle of the carrier can be adjusted quickly and easily to control the flow rate of the slurry in the magnetic separation area, so as to better select the magnetic materials in the slurry. (4) The reduction motor of a well-known brand is used, which is reliable and durable. The conveyor belt can be adjusted in time according to the different material shapes of the magnetic materials in the slurry to achieve better iron removal effect. (5) The conveyor belt is made of high-strength and high-quality composite materials, with a long service life and obvious unloading effect. (6) The feed box adopts a double-layer perforated plate structure, which ensures smooth and uniform distribution of materials and a thin slurry layer. It is equipped with upper and lower high-pressure water automatic ore flushing devices. The upper ore flushing device is responsible for flushing the non-magnetic ore slurry mixed with the magnetic material, and the lower ore flushing device uses high-pressure water to flush the magnetic material particles attached to the conveyor belt.

The GTGB permanent magnet high-field plate magnetic separator operates as follows: ore slurry is fed into the feed box through an inlet pipe. After thorough dispersion, it is evenly distributed on the conveyor belt above the plate magnetic system. Under the influence of gravity, the slurry flows downward along the inclined conveyor belt. The non-magnetic slurry eventually flows into the non-magnetic slurry hopper in the lower trough. The high-intensity magnetic field, reaching up to 15,000 gauss, firmly attracts the magnetic material contained in the slurry to the conveyor belt. The motor drives the drive roller assembly, moving the conveyor belt and the magnetic material on it upward along the inclined direction. The magnetic material on the conveyor belt then enters the non-magnetic field area. Under the influence of gravity and high-pressure flushing water, the magnetic material and the flushing water flow into the magnetic slurry hopper in the lower trough.

The GTGB plate magnetic separator, used in conjunction with the GTLH vertical ring magnetic separator, can maximize the separation of fine-grained, weakly magnetic materials contained in the slurry. It is a core equipment for iron removal and impurity removal in non-metallic ore beneficiation.

-

High Gradient Vertical Ring Magnetic Separator

2025年8月15日 Guote Views (449) +Read MoreDesigned and manufactured by Weifang Guote Mining Equipment Co., Ltd., the GTLH series vertical ring high-gradient magnetic separator is a high-performance, technologically advanced high-magnetic separation device renowned both domestically and internationally. It is widely used for the beneficiation of weakly magnetic minerals such as hematite, limonite, siderite, ilmenite, and wolframite, as well as for the iron removal and purification of non-metallic minerals such as quartz, feldspar, nepheline, and kaolin. It boasts excellent beneficiation performance, low energy consumption, minimal maintenance, high reliability, and robust adaptability to ore properties, resulting in an average operating rate exceeding 99%.

The GTLH vertical ring high-gradient magnetic separator primarily consists of a frame, lower core and discharge chute, lower yoke and magnetic columns, excitation coil and cooling system, upper core and yoke, non-magnetic swivel, magnetic media cartridge, feed hopper, rinse hopper, concentrate hopper, middling hopper, tailings hopper, concentrate flushing device, level hopper, swivel drive mechanism, pulsating mechanism, and electrical control cabinet.

The excitation coil of the GTLH vertical ring high-gradient magnetic separator utilizes high-quality conductors and a multi-layer, three-dimensional, cross-winding structure. The oil circuit is unobstructed and well-connected. The coil winding provides high mechanical strength, strong deformation resistance, high insulation strength, a large heat exchange area, and excellent heat dissipation. The excitation coil is immersed in cooling transformer oil and cooled by the forced flow of the cooling oil pump. The heated cooling oil is pumped to an external, high-efficiency plate heat exchanger. The heat is effectively dissipated through the radiator’s efficient fins, and the cooled transformer oil returns to the excitation coil system, beginning a new cycle of cooling. This cooling method offers rapid cooling, simple structure, easy installation, and a compact footprint. It truly achieves oil-water cooling, is highly efficient and energy-efficient, reduces coil temperature rise, and maintains a stable magnetic field. This method enables the excitation coil to generate a high-gradient magnetic field at low temperatures, with an induced magnetic field strength of up to 2.3 Tesla. The excitation coil is equipped with a comprehensive temperature protection system that displays the operating temperature of each coil in real time and features two-level over-temperature protection. If the temperature exceeds the limit, an alarm is triggered, cutting off the excitation current and placing the equipment into a protective mode.

The magnetic medium utilizes our company’s proprietary structure, ensuring excellent beneficiation performance. With a feed size of 1.2 mm and normal flushing water, the magnetic medium remains clog-free and has a long service life. The swivel drive mechanism utilizes an internationally renowned brand, ensuring stable operation and a long service life. Driven by the stroke box, the pulsating mechanism reciprocates, repeatedly flushing mineral particles adsorbed on the magnetic medium surface with slurry, effectively eliminating mechanical inclusions and improving concentrate grade. The pulsating stroke box utilizes a high-thrust, four-roller reciprocating mechanism, ensuring stable operation over long periods of operation and enhancing equipment availability. The tailings valve features a fluid-resistant design and a special wear-resistant material coating on the inner wall, significantly enhancing its wear resistance. The use of well-known low-voltage electrical components and PLC components ensures safe, reliable operation and a long service life. An advanced soft-start function prevents transient current shock to the coil. The system also features an advanced fault self-diagnosis system with remote assistance capabilities. In the event of a malfunction, fault information is immediately transmitted to the company’s customer service center.

The GTLH vertical ring high-gradient magnetic separator operates as follows: The ring rotates vertically, generating a high-gradient magnetic field within the magnetic medium. Slurry is fed through the ring through the gaps in the upper iron yoke. Magnetic particles in the slurry are attracted to the surface of the magnetic medium and carried to the top, where the ring rotates, to the non-magnetic area. Flushing water then flushes the magnetic material into the concentrate hopper, while non-magnetic slurry flows through the gaps in the lower iron yoke and is discharged into the tailings hopper.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516