-

Guote high-purity sand production line equipment was shipped in its entirety, helping the photovolta…

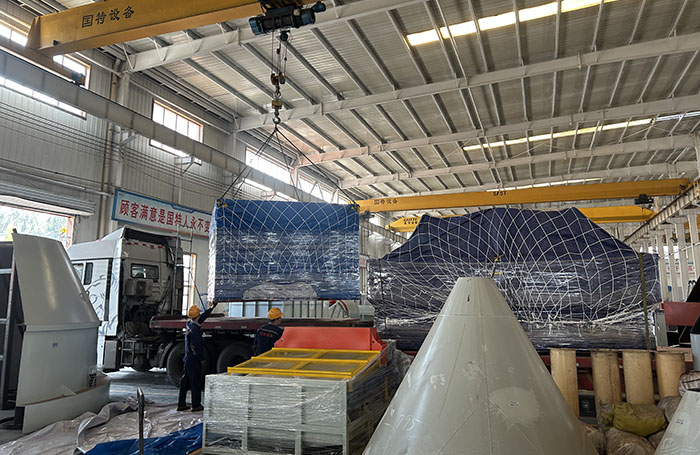

2025-12-22 Guote Views (568) +Read MoreRecently, the main equipment for a 300,000-ton-per-year high-purity quartz sand production line designed and manufactured by Weifang Guote Mining Equipment Co., Ltd. for Southeast China has been completed. The core equipment, including drum screens, desliming buckets, hydraulic classifiers, obstructed settling machines, wet belt magnetic separators, and wet high intensity magnetic separators (WHIMS), has been loaded and shipped in batches, marking an important step forward for my country in the localization of high-purity sand equipment and the integration of complete production lines.

This production line, designed by Guote Equipment based on the characteristics of the customer’s raw ore and the actual working conditions, is a professional process that can fully cover the entire process of quartz sand from coarsening to refining. The drum screen and desliming hopper complete the initial screening of raw materials and clay removal; the hydraulic classifier and obstructed settling machine achieve precise classification of quartz sand of different particle sizes and efficient removal of fine particles; the wet belt magnetic separator and wet high intensity magnetic separator (WHIMS) form a “coarsening and refining” magnetic separation system, which can greatly reduce the Fe₂O₃ content and meet the standards for sand used in photovoltaic glass and semiconductors.

The completion and commissioning of this production line will provide a stable and reliable supply of high-purity quartz sand raw materials for downstream photovoltaic glass and high-end electronic materials industries, further promoting the independent control and high-quality development of my country’s silicon-based materials industry chain. Weifang Guote Mining Equipment Co., Ltd. will continue to adhere to the principle of “leading technology, reliable equipment, and comprehensive service,” providing customers with a full-chain service from experimental research and process design to complete line delivery and after-sales service, helping my country’s non-metallic mineral industry continuously move towards high-end, intelligent, and green development.

-

Guote Equipment Showcases at the 2nd Panxi Mineral Resources Conference

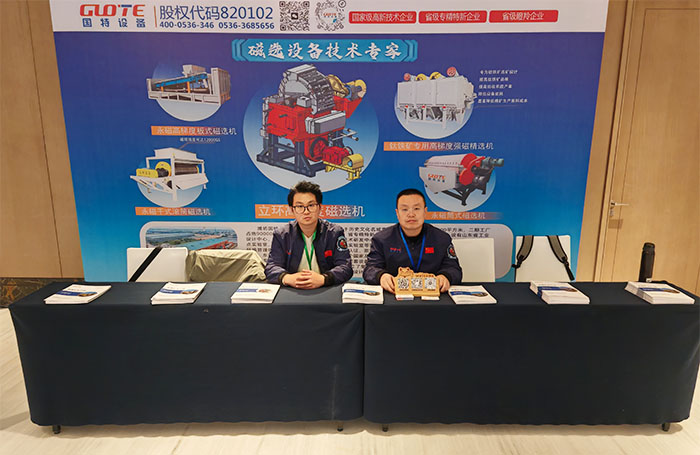

2025-12-20 Guote Views (349) +Read MoreWhen the “national strategic resource treasure trove” of Panzhihua-Xichang meets the power of mining innovation, an industrial feast concerning the efficient utilization of vanadium and titanium resources is about to begin! From December 18th to 20th, 2025, the 2nd Panzhihua-Xichang Mineral Resources Conference was grandly held in Panzhihua, Sichuan. Weifang Guote Mining Equipment Co., Ltd. (hereinafter referred to as “Guote Equipment”), as a national high-tech enterprise and a benchmark brand in the field of mining equipment, made a stunning appearance with its green and intelligent mineral processing solution customized for the characteristics of vanadium and titanium resources in Panzhihua-Xichang, and contributed to the high-quality development of regional mineral resources with more than 20 years of technical accumulation.

At the conference, the Guote Equipment exhibition area attracted the attention of numerous mining companies and research institutions. The professional technical team engaged in in-depth discussions with attendees on green development paths for vanadium and titanium resources through case studies and customized solutions. Whether providing process optimization suggestions for specific mines or facilitating technical collaboration on comprehensive solid waste utilization, Guote Equipment promoted a precise match between technological needs and industrial applications through a “production-education-research collaboration” approach, earning the “Outstanding Supplier Award for Supporting Equipment.”

Resources are limited, but innovation is limitless. The 2nd Panxi Mineral Resources Conference has built a platform for technical exchange and win-win cooperation within the industry. Guote Equipment will seize this opportunity to further deepen its industry-academia-research cooperation with enterprises in the Panxi region, focusing on core issues such as efficient recovery of low-grade ore and co-utilization of solid waste. We will continuously iterate our technical solutions to contribute Guote’s strength to ensuring national strategic resource security and helping achieve the “dual carbon” goals!

-

Guote Equipment successfully shipped ball mills, wet belt magnetic separator, and sand dryers, contr…

2025-12-15 Guote Views (364) +Read MoreRecently, a batch of high-performance mining equipment manufactured by Weifang Guote Mining Equipment Co., Ltd.—including a large rotary drum dryer, an energy-saving ball mill, and a high-efficiency wet belt magnetic separator,—successfully completed acceptance and loading at the company’s factory and was shipped to the customer’s project site. This shipment marks the official entry of this batch of equipment into the delivery and application phase, providing crucial support for the customer’s production line upgrades, capacity increases, and efficient comprehensive utilization of resources.

Rotary drum sand dryer.

The dryer shipped this time is a rotary dryer, which adopts a high-efficiency heating method and is equipped with an innovative lifting plate system inside the drum to ensure full contact between the material and the hot air, resulting in high heat exchange efficiency. The entire system is equipped with an energy-saving hot air furnace and a high-efficiency dust removal system, ensuring stable operation, low energy consumption, and compliance with environmental standards.

Ball Mill.

The ball mill shipped this time meets the customer’s capacity and fineness requirements. The equipment liners and grinding media are optimized for the characteristics of the ore being processed by the customer, aiming to achieve stable operation with low energy consumption and high grinding efficiency.Wet Belt Magnetic Separator.

The flat-plate high-gradient magnetic separator shipped this time uses high-performance magnetic materials, featuring high magnetic field strength and uniform distribution, resulting in high separation efficiency. Its structural design emphasizes wear resistance and ease of maintenance, effectively separating magnetic minerals from slurry, improving concentrate grade, and reducing tailings recovery rate.This successful shipment is a significant achievement resulting from the close collaboration between Guote Equipment and its client.

For the client, Guote Equipment’s integrated solution of “core equipment + process support” will provide a solid guarantee for building an efficient, stable, and intelligent modern production enterprise, helping them reduce costs, increase efficiency, and achieve sustainable development.

For Guote, this successful shipment further solidifies the company’s market position and brand influence in the field of complete mining equipment, and is another successful practice of the company’s philosophy of “creating value for customers with reliable equipment and professional services.”

-

The 2nd China Shale Oil and Gas Exploration and Development Technology and Equipment Exchange Confer…

2025-12-05 Guote Views (242) +Read MoreRecently, the 2nd China Shale Oil and Gas Exploration and Development Technology and Equipment Exchange Conference was held in Chengdu. Weifang Guote Mining Equipment Co., Ltd., a benchmark enterprise in the mining equipment field, was invited to participate in the conference. Mr. Wang Guozhou, Chairman of the Board of Directors, took the stage to speak on the core technological achievements, focusing on the innovative process of high-performance preparation of quartz sand fracturing proppant. He deeply decoded the R&D breakthroughs and industrial practices of Guote equipment. With its core technical strength and cutting-edge industry insights, Guote became the focus of the conference and won high praise from all the guests.

Shale oil and gas is a crucial pillar of energy security strategy, and improving its exploration and development efficiency relies heavily on technological innovation in core equipment and materials. As the “backbone” of shale oil and gas fracturing operations, the purity, strength, and conductivity of fracturing proppant directly determine fracturing effectiveness and oil and gas recovery rates, making it a core focus of the industry.

At this conference, Weifang Guote Mining Equipment Co., Ltd. unveiled its groundbreaking innovative solution. This solution integrates multiple core patented technologies, achieving a disruptive upgrade to the entire fracturing sand preparation process. Through the sharing of practical case studies, Guote’s technological strength was further demonstrated, showcasing the innovative vitality of Chinese mining equipment companies to the industry. This provides a feasible solution for the large-scale economic development of shale oil and gas and is expected to play a significant role in energy structure adjustment and energy security strategies.

-

The 7th China Mining Industry-University-Research Integration Conference 2025

2025-12-02 Guote Views (349) +Read MoreAs green development becomes the core issue of mining transformation, and as industry-academia-research integration becomes the key path to technological breakthroughs, the 7th China Mining Industry-Academia-Research Integration Conference 2025 was held in Chongqing as scheduled. As a leading enterprise in China’s mining equipment manufacturing field, the high-tech enterprise Weifang Guote Mining Equipment Co., Ltd. made a grand appearance with its major breakthrough in magnetic separation technology and a full range of core equipment, interpreting the core connotation of “technology empowering high-quality development of the mining industry” with its innovative strength, becoming one of the highlights of the conference.

Leveraging its core technological advantages, Guote Equipment showcased a comprehensive matrix of magnetic separation equipment covering all scenarios in the metal and non-metal mineral industries at the conference. This included core products such as permanent magnet drum separators for strongly magnetic minerals, vertical ring high-gradient magnetic separators for fine-grained weakly magnetic minerals, and ilmenite beneficiation machines specifically designed for ilmenite purification. These devices combine advantages such as high magnetic field strength, low demagnetization rate, large processing capacity, and automated control.

The 7th China Mining Industry-University-Research Integration Conference provided an important platform for technical exchange and cooperation within the industry. Guote Equipment, taking advantage of this conference, fully demonstrated the innovative vitality of Chinese mining equipment enterprises. It is believed that through the continuous advancement of deep integration of industry, academia, and research, Guote Equipment will provide more competitive equipment support for the green development of mineral resources, and work hand in hand with industry partners to create a new blueprint for high-quality development in the mining industry.

-

2025 China Vanadium-Titanium Industry Chain Conference

2025-11-29 Guote Views (341) +Read MoreFrom November 27th to 28th, the 2025 China Vanadium-Titanium Industry Chain Conference was held in Hebei, China. The conference aimed to build an efficient platform for connecting the industry chain and supply chain, strengthen communication and cooperation; deeply explore industry development trends, policy guidance, and technological bottlenecks to achieve the industry’s goals of high-end, intelligent, and green development; plan for future development and guide the industry to seize opportunities; and showcase the latest achievements, cutting-edge technologies, and high-end products of the vanadium-titanium industry to enhance brand influence.

Wang Guozhou, Chairman of Weifang Guote Mining Equipment Co., Ltd., delivered a special report on “Research and Application of Magnetic Separation Equipment in Titanium Concentrate Preparation,” sharing the advantages of Weifang Guote’s high-gradient strong magnetic separator for ilmenite, dry strong magnetic drum separator, and wet high intensity magnetic separator.

Guote’s ilmenite beneficiation machine plays a crucial role in the vanadium-titanium industry, primarily in the following aspects:

1. Improving ilmenite grade to meet smelting requirements

• High-efficiency separation: Ilmenite often occurs alongside gangue minerals (such as pyroxene and feldspar), resulting in low-grade ore. The beneficiation machine efficiently separates ilmenite from impurities using physical or physicochemical methods (such as gravity separation, magnetic separation, and flotation), increasing the TiO₂ grade from 10%~20% in the primary ore to over 45%~50%, meeting the raw material standards for titanium slag smelting or chloride-process titanium dioxide production.

• Reducing downstream costs: High-grade concentrate significantly reduces energy consumption and auxiliary material consumption in subsequent smelting, improving production efficiency.2. Optimizing the comprehensive utilization of vanadium-titanium resources

• Co-processing of vanadium-titanium magnetite: Vanadium-titanium magnetite is a major carrier of vanadium-titanium resources in China (e.g., in the Panzhihua-Xichang region of Sichuan), where iron, titanium, and vanadium coexist. The beneficiator can simultaneously recover vanadium-containing iron concentrate during the sorting of ilmenite, providing raw materials for vanadium extraction (such as vanadium slag), achieving “multi-mining from one ore.”

• Tailings Resource Utilization: The sorted tailings can be further recycled to recover other valuable elements (such as cobalt, nickel, chromium, etc.), reducing resource waste.3. Supporting Key Links in the Titanium Industry Chain

• Titanium Dioxide Production: Titanium concentrate is the core raw material for the production of titanium dioxide using the sulfuric acid or chloride process. The stable operation of the beneficiator ensures the supply of high-quality titanium concentrate, directly affecting the purity and performance of titanium dioxide.

• Sponge Titanium and Titanium Materials: High-grade titanium concentrate, after being smelted into titanium slag or synthesized rutile, can be used to produce sponge titanium and high-end titanium alloys, meeting the needs of aerospace, military, medical, and other fields.4. Promoting Technological Upgrading and Environmental Protection

• Domestic Production Breakthrough: Its research and application reduce dependence on foreign countries and improve sorting efficiency through automation and low-energy consumption design.

• Reduced Pollution: High-efficiency sorting can reduce tailings emissions, and when combined with environmentally friendly processes (such as acid-free flotation), it alleviates environmental pressure.The Guote titanium-iron ore beneficiation machine is a key pre-processing link in the vanadium-titanium resource industry chain. Its technological level directly affects the quality of titanium concentrate, the efficiency of comprehensive resource utilization, and the competitiveness of downstream products. Through continuous equipment innovation, significant progress has been made in the sorting of complex associated minerals, providing a solid guarantee for the stable supply of strategic vanadium-titanium resources.

-

The 4th Northeast Steel Raw Material Market and Mining Technology Development Conference

2025-11-27 Guote Views (484) +Read MoreThe highly anticipated “4th Northeast Steel Raw Material Market and Mining Technology Development Conference 2025” was held on November 26, 2025. As a leading enterprise in China’s mining equipment manufacturing industry, Weifang Guote Mining Equipment Co., Ltd. was invited to participate and showcased its core product—a series of high-efficiency magnetic separation equipment. The company demonstrated its innovative strength in improving resource utilization, reducing beneficiation costs, and promoting green mine construction to the mining industry in Northeast China and throughout the country. Based on its advanced magnetic separation technology, the company also provides customized equipment and process support.

At this exhibition, Weifang Guote Mining Equipment Co., Ltd. focused its showcase on the technological innovation and application of its core product—magnetic separators. The exhibited equipment series included permanent magnet drum separators for strongly magnetic minerals, vertical ring high-gradient magnetic separators(WHIMS) suitable for fine-grained weakly magnetic minerals, and ilmenite beneficiation machines specifically designed for ilmenite purification. These devices feature high magnetic fields, low demagnetization rates, large throughput, and automated control, effectively improving concentrate grade and metal recovery rates while significantly reducing operating costs and maintenance requirements. Therefore, they attracted numerous mining companies, industry experts, and partners to stop by for consultation and in-depth exchanges.

Through this exhibition, Weifang Guote Mining Equipment Co., Ltd. not only successfully showcased its professional strength in magnetic separation technology, but also established close connections with numerous potential customers and industry partners. The company stated that it will continue to uphold the principles of “technological innovation, quality first, and service-oriented,” increase R&D investment, continuously optimize product performance, expand application areas, and provide domestic and international mining customers with more efficient, energy-saving, and environmentally friendly magnetic separation and purification solutions. Guote aims to contribute its strength to promoting the advancement of mining and beneficiation technology and the high-quality development of the steel raw material industry in my country.

-

Technology Leading the Way, Creating the Future! The 9th Quartz Conference 2025

2025-11-21 Guote Views (509) +Read MoreAs the quartz silica sand industry reaches a critical juncture of high-end upgrading, a grand industry event is empowering technological exchange and cooperation. From November 20-21, 2025, the “9th National Quartz Conference and Exhibition,” hosted by China Powder Network, grandly opened in Xuzhou, Jiangsu Province. This conference, with the core objectives of strengthening supply chain security and promoting the domestic substitution of high-end products, brought together elite enterprises and authoritative experts from the entire quartz industry chain.

Weifang Guote Mining Equipment Co., Ltd. (Booth No.: B27), a national high-tech enterprise and a leader in the silica sand processing equipment field, participated in the exhibition with its full range of core equipment and customized solutions, becoming one of the highlights of the conference.

During the conference, the elite team from Guote Equipment was on-site, providing attendees with one-on-one technical consultations and hosting a special session on “High-Efficiency Purification Technology for Quartz Sand.” They analyzed key process challenges such as magnetic separation for iron removal and acid washing purification using practical case studies.

To allow attendees to more intuitively understand the implementation effects of their solutions, Guote Equipment showcased over 200 benchmark EPC projects worldwide at its booth. These included: a 2 million-ton-per-year quartz glass sand project, where Guote provided full-process services from mineral processing experiments to overall line commissioning, utilizing a GTLH-type oil-water composite cooling vertical ring magnetic separator (WHIMS magnetic separator), achieving stable operation and 100% customer satisfaction; a 1 million-ton-per-year glass sand production line, achieving significant purification effects through the combination of multiple magnetic separation devices, becoming a regional industry model project; and the successful operation of projects such as a 300,000-ton-per-year slab sand production line in Southeast Asia and a 500,000-ton-per-year glass sand production line in Africa, fully demonstrating Guote Equipment’s international service capabilities.

-

Installation site of 600,000 tpa quartz glass sand equipment in Indonesia

2025-11-12 Guote Views (839) +Read MoreIn Belitung, Indonesia, the Guote Mining equipment team is working diligently on the construction and installation of this silica sand production line, which has an annual capacity of 600,000 tons of quartz glass sand. Installation is nearing completion, and the line’s commissioning will boost the development of the building materials industry in Southeast Asia, while also marking Guote Mining’s entry onto a larger global stage.

This quartz glass sand production line, centered around a Guote Wet High Intensity Magnetic Separator, also includes a vibrating screen, desliming hopper, hydraulic classifier, dewatering screen, scrubbing machine, and spiral chute. The entire production line was custom-designed by Guote based on the client’s ore and site conditions, truly achieving an EPC (Engineering, Procurement, and Construction) turnkey service encompassing experimental research, mine design, equipment manufacturing and procurement, packaging and transportation, construction, installation, and commissioning.

As a national high-tech enterprise, a specialized and innovative enterprise, and an innovative company, Guote Mining Equipment has an in-house municipal-level key laboratory for silicon materials and an engineering laboratory for non-metallic mine purification equipment. In terms of product quality control, the company strictly adheres to international standards, and its products have successfully passed ISO9001 quality system certification and EU CE certification. With its outstanding R&D capabilities, the company possesses dozens of patented technologies, covering multiple aspects such as product design, processes, and functions, giving its products a unique advantage in market competition.

From initial project planning and repeated validation of experimental designs to the production, installation, and commissioning of the entire equipment line, Guote Company boasts a professional team providing one-stop solutions for its clients. The company consistently adheres to a reliable, efficient, and simple business philosophy, enabling clients to easily use and maintain their equipment, minimizing their operating costs and risks.

Friends from Southeast Asia are welcome to visit us in person.

-

Silica sand processing equipment shipped to Algeria, Africa

2025-11-07 Guote Views (529) +Read MoreIn April 2025, a client from Algeria, Africa, signed a contract with Guote Mining Equipment for a 300,000-ton/year quartz glass sand production line project. After six months, all equipment for the project has been manufactured and is now ready for shipment. The project includes our core products, such as WHIMS magnetic separator, Belt type magnetic separator, scrubbing machine, dewatering screen, vibrating screen, drum screen, desliming hopper, and hydraulic classifier.

From pre-selection equipment, scrubbing equipment, classifying equipment, screening equipment, magnetic separation equipment, dewatering equipment, to the complete production line equipment, over 20 truckloads of goods have been successfully transported to the port over six days for centralized loading onto ships.

We sincerely thank our African client for their trust and support! Meanwhile, our installation and after-sales service team is processing all necessary travel documents and departing for the Algerian project site, striving to arrive simultaneously with the equipment to ensure the project is put into production quickly and becomes effective as soon as possible.

The quartz glass sand processing equipment delivered this time was all customized solutions independently and specifically developed by our design team based on the client’s actual ore characteristics and production needs. As an EPC general contracting service provider with many years of experience in the industry, Guote Equipment always adheres to a client-centric approach, rejecting vague discussions and simple replication.

Each solution is meticulously designed based on experimental data and operational condition surveys, combined with the client’s specific goals, embodying the professional experience and dedication of the Guote team, and committed to providing clients with truly production-fitting, stable, and efficient overall solutions.

The successful shipment of this complete silica sand production line marks a new milestone in Guote Equipment’s EPC general contracting capabilities in the international market, further demonstrating our technical strength and project execution capabilities in the global mineral processing field.

The successful delivery of this project not only reflects Guote Equipment’s professional level in the field of complete quartz sand production line equipment, but also provides reliable technical support and equipment assurance for the global glass sand raw material supply, helping downstream industries achieve high-quality and sustainable development.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

This production line, designed by Guote Equipment based on the characteristics of the customer’s raw ore and the actual working conditions, is a professional process that can fully cover the entire process of quartz sand from coarsening to refining. The drum screen and desliming hopper complete the initial screening of raw materials and clay removal; the hydraulic classifier and obstructed settling machine achieve precise classification of quartz sand of different particle sizes and efficient removal of fine particles; the wet belt magnetic separator and wet high intensity magnetic separator (WHIMS) form a “coarsening and refining” magnetic separation system, which can greatly reduce the Fe₂O₃ content and meet the standards for sand used in photovoltaic glass and semiconductors.

This production line, designed by Guote Equipment based on the characteristics of the customer’s raw ore and the actual working conditions, is a professional process that can fully cover the entire process of quartz sand from coarsening to refining. The drum screen and desliming hopper complete the initial screening of raw materials and clay removal; the hydraulic classifier and obstructed settling machine achieve precise classification of quartz sand of different particle sizes and efficient removal of fine particles; the wet belt magnetic separator and wet high intensity magnetic separator (WHIMS) form a “coarsening and refining” magnetic separation system, which can greatly reduce the Fe₂O₃ content and meet the standards for sand used in photovoltaic glass and semiconductors. The completion and commissioning of this production line will provide a stable and reliable supply of high-purity quartz sand raw materials for downstream photovoltaic glass and high-end electronic materials industries, further promoting the independent control and high-quality development of my country’s silicon-based materials industry chain. Weifang Guote Mining Equipment Co., Ltd. will continue to adhere to the principle of “leading technology, reliable equipment, and comprehensive service,” providing customers with a full-chain service from experimental research and process design to complete line delivery and after-sales service, helping my country’s non-metallic mineral industry continuously move towards high-end, intelligent, and green development.

The completion and commissioning of this production line will provide a stable and reliable supply of high-purity quartz sand raw materials for downstream photovoltaic glass and high-end electronic materials industries, further promoting the independent control and high-quality development of my country’s silicon-based materials industry chain. Weifang Guote Mining Equipment Co., Ltd. will continue to adhere to the principle of “leading technology, reliable equipment, and comprehensive service,” providing customers with a full-chain service from experimental research and process design to complete line delivery and after-sales service, helping my country’s non-metallic mineral industry continuously move towards high-end, intelligent, and green development.

At the conference, the Guote Equipment exhibition area attracted the attention of numerous mining companies and research institutions. The professional technical team engaged in in-depth discussions with attendees on green development paths for vanadium and titanium resources through case studies and customized solutions. Whether providing process optimization suggestions for specific mines or facilitating technical collaboration on comprehensive solid waste utilization, Guote Equipment promoted a precise match between technological needs and industrial applications through a “production-education-research collaboration” approach, earning the “Outstanding Supplier Award for Supporting Equipment.”

At the conference, the Guote Equipment exhibition area attracted the attention of numerous mining companies and research institutions. The professional technical team engaged in in-depth discussions with attendees on green development paths for vanadium and titanium resources through case studies and customized solutions. Whether providing process optimization suggestions for specific mines or facilitating technical collaboration on comprehensive solid waste utilization, Guote Equipment promoted a precise match between technological needs and industrial applications through a “production-education-research collaboration” approach, earning the “Outstanding Supplier Award for Supporting Equipment.” Resources are limited, but innovation is limitless. The 2nd Panxi Mineral Resources Conference has built a platform for technical exchange and win-win cooperation within the industry. Guote Equipment will seize this opportunity to further deepen its industry-academia-research cooperation with enterprises in the Panxi region, focusing on core issues such as efficient recovery of low-grade ore and co-utilization of solid waste. We will continuously iterate our technical solutions to contribute Guote’s strength to ensuring national strategic resource security and helping achieve the “dual carbon” goals!

Resources are limited, but innovation is limitless. The 2nd Panxi Mineral Resources Conference has built a platform for technical exchange and win-win cooperation within the industry. Guote Equipment will seize this opportunity to further deepen its industry-academia-research cooperation with enterprises in the Panxi region, focusing on core issues such as efficient recovery of low-grade ore and co-utilization of solid waste. We will continuously iterate our technical solutions to contribute Guote’s strength to ensuring national strategic resource security and helping achieve the “dual carbon” goals!

Rotary drum sand dryer.

Rotary drum sand dryer.

Shale oil and gas is a crucial pillar of energy security strategy, and improving its exploration and development efficiency relies heavily on technological innovation in core equipment and materials. As the “backbone” of shale oil and gas fracturing operations, the purity, strength, and conductivity of fracturing proppant directly determine fracturing effectiveness and oil and gas recovery rates, making it a core focus of the industry.

Shale oil and gas is a crucial pillar of energy security strategy, and improving its exploration and development efficiency relies heavily on technological innovation in core equipment and materials. As the “backbone” of shale oil and gas fracturing operations, the purity, strength, and conductivity of fracturing proppant directly determine fracturing effectiveness and oil and gas recovery rates, making it a core focus of the industry. At this conference, Weifang Guote Mining Equipment Co., Ltd. unveiled its groundbreaking innovative solution. This solution integrates multiple core patented technologies, achieving a disruptive upgrade to the entire fracturing sand preparation process. Through the sharing of practical case studies, Guote’s technological strength was further demonstrated, showcasing the innovative vitality of Chinese mining equipment companies to the industry. This provides a feasible solution for the large-scale economic development of shale oil and gas and is expected to play a significant role in energy structure adjustment and energy security strategies.

At this conference, Weifang Guote Mining Equipment Co., Ltd. unveiled its groundbreaking innovative solution. This solution integrates multiple core patented technologies, achieving a disruptive upgrade to the entire fracturing sand preparation process. Through the sharing of practical case studies, Guote’s technological strength was further demonstrated, showcasing the innovative vitality of Chinese mining equipment companies to the industry. This provides a feasible solution for the large-scale economic development of shale oil and gas and is expected to play a significant role in energy structure adjustment and energy security strategies.

Leveraging its core technological advantages, Guote Equipment showcased a comprehensive matrix of magnetic separation equipment covering all scenarios in the metal and non-metal mineral industries at the conference. This included core products such as permanent magnet drum separators for strongly magnetic minerals, vertical ring high-gradient magnetic separators for fine-grained weakly magnetic minerals, and ilmenite beneficiation machines specifically designed for ilmenite purification. These devices combine advantages such as high magnetic field strength, low demagnetization rate, large processing capacity, and automated control.

Leveraging its core technological advantages, Guote Equipment showcased a comprehensive matrix of magnetic separation equipment covering all scenarios in the metal and non-metal mineral industries at the conference. This included core products such as permanent magnet drum separators for strongly magnetic minerals, vertical ring high-gradient magnetic separators for fine-grained weakly magnetic minerals, and ilmenite beneficiation machines specifically designed for ilmenite purification. These devices combine advantages such as high magnetic field strength, low demagnetization rate, large processing capacity, and automated control. The 7th China Mining Industry-University-Research Integration Conference provided an important platform for technical exchange and cooperation within the industry. Guote Equipment, taking advantage of this conference, fully demonstrated the innovative vitality of Chinese mining equipment enterprises. It is believed that through the continuous advancement of deep integration of industry, academia, and research, Guote Equipment will provide more competitive equipment support for the green development of mineral resources, and work hand in hand with industry partners to create a new blueprint for high-quality development in the mining industry.

The 7th China Mining Industry-University-Research Integration Conference provided an important platform for technical exchange and cooperation within the industry. Guote Equipment, taking advantage of this conference, fully demonstrated the innovative vitality of Chinese mining equipment enterprises. It is believed that through the continuous advancement of deep integration of industry, academia, and research, Guote Equipment will provide more competitive equipment support for the green development of mineral resources, and work hand in hand with industry partners to create a new blueprint for high-quality development in the mining industry.

Wang Guozhou, Chairman of Weifang Guote Mining Equipment Co., Ltd., delivered a special report on “Research and Application of Magnetic Separation Equipment in Titanium Concentrate Preparation,” sharing the advantages of Weifang Guote’s high-gradient strong magnetic separator for ilmenite, dry strong magnetic drum separator, and wet high intensity magnetic separator.

Wang Guozhou, Chairman of Weifang Guote Mining Equipment Co., Ltd., delivered a special report on “Research and Application of Magnetic Separation Equipment in Titanium Concentrate Preparation,” sharing the advantages of Weifang Guote’s high-gradient strong magnetic separator for ilmenite, dry strong magnetic drum separator, and wet high intensity magnetic separator.

At this exhibition, Weifang Guote Mining Equipment Co., Ltd. focused its showcase on the technological innovation and application of its core product—magnetic separators. The exhibited equipment series included permanent magnet drum separators for strongly magnetic minerals, vertical ring high-gradient magnetic separators(WHIMS) suitable for fine-grained weakly magnetic minerals, and ilmenite beneficiation machines specifically designed for ilmenite purification. These devices feature high magnetic fields, low demagnetization rates, large throughput, and automated control, effectively improving concentrate grade and metal recovery rates while significantly reducing operating costs and maintenance requirements. Therefore, they attracted numerous mining companies, industry experts, and partners to stop by for consultation and in-depth exchanges.

At this exhibition, Weifang Guote Mining Equipment Co., Ltd. focused its showcase on the technological innovation and application of its core product—magnetic separators. The exhibited equipment series included permanent magnet drum separators for strongly magnetic minerals, vertical ring high-gradient magnetic separators(WHIMS) suitable for fine-grained weakly magnetic minerals, and ilmenite beneficiation machines specifically designed for ilmenite purification. These devices feature high magnetic fields, low demagnetization rates, large throughput, and automated control, effectively improving concentrate grade and metal recovery rates while significantly reducing operating costs and maintenance requirements. Therefore, they attracted numerous mining companies, industry experts, and partners to stop by for consultation and in-depth exchanges. Through this exhibition, Weifang Guote Mining Equipment Co., Ltd. not only successfully showcased its professional strength in magnetic separation technology, but also established close connections with numerous potential customers and industry partners. The company stated that it will continue to uphold the principles of “technological innovation, quality first, and service-oriented,” increase R&D investment, continuously optimize product performance, expand application areas, and provide domestic and international mining customers with more efficient, energy-saving, and environmentally friendly magnetic separation and purification solutions. Guote aims to contribute its strength to promoting the advancement of mining and beneficiation technology and the high-quality development of the steel raw material industry in my country.

Through this exhibition, Weifang Guote Mining Equipment Co., Ltd. not only successfully showcased its professional strength in magnetic separation technology, but also established close connections with numerous potential customers and industry partners. The company stated that it will continue to uphold the principles of “technological innovation, quality first, and service-oriented,” increase R&D investment, continuously optimize product performance, expand application areas, and provide domestic and international mining customers with more efficient, energy-saving, and environmentally friendly magnetic separation and purification solutions. Guote aims to contribute its strength to promoting the advancement of mining and beneficiation technology and the high-quality development of the steel raw material industry in my country.