Planning and Design Department

Guote has a professional planning and design department that provides customized designs for large and medium-sized mines worldwide. Based on mineral testing results, the Guote design team develops equipment and process configuration plans, adhering to the principles of facilitating production, facilitating management, ensuring mining safety, conserving land, and reducing infrastructure investment. We are committed to providing clients with professional and reliable mineral design solutions.

Congo Quartz Sand Pickling Plate Sand Project

Brazil 300,000 tons/year ilmenite project

Large manganese ore dressing plant in Russia

01

Comprehensive Expert Team

Guote Mining Equipment consists of mining, mineral processing, civil engineering, electrical, automation, and steel structure, covering geology, mining, mining machinery, mineral processing, water supply and drainage, HVAC, tailings, pipelines, budget estimation, thermal engineering, master plan, civil engineering, electrical, automation, 3D design, steel structure, etc. It has dozens of professional designers, forming a complete team of experts.

02

Innovative and Targeted Mine Design

There are no two identical mines in the world, so Guote tailors a design plan for each mine rather than simply copying blueprints.

- Comprehensive site investigation: covering ore supply, site location, water and electricity, transportation, geography, etc.

- Determining a feasibility plan: The Planning and Design Department collects information and conducts a feasibility study, ultimately determining a feasible plan and writing a feasibility study report.

- Preparing construction drawings: After conducting a preliminary design review of selected construction drawings, the Planning and Design Department begins preparing construction drawings based on the design plan. They also conduct a "design briefing" with construction supervisors on site, detailing key design points, strict standards, and important details.

For the mining stage of the project, Guote can formulate preliminary exploration or mining plans based on geological exploration data, including feasibility study reports, preliminary design, and construction design for each stage.

03

Ability to Design According to Multiple National Standards

Guote Mining is capable of designing in accordance with Chinese standards, Australian JORC standards, Valmin specifications, and Canadian NI43-101 standards. Furthermore, it has established strategic partnerships with mining design consulting firms in Australia, Canada, and other regions to leverage their strengths. In the "E" phase of EPCM, the plan is jointly determined by both parties, with Guote primarily responsible for the specific work, while design review and qualification are handled by the Australian or Canadian partners. For regions such as Africa, South America, Central Asia, and Southeast Asia, Guote can design in accordance with Chinese, Australian, Canadian, and local national standards and specifications.

Guote Mining also provides pre-sales processing plant design services. Based on client needs and actual production experience from similar mines, we can provide a preliminary beneficiation process flow diagram, equipment list, and total investment estimate.

-

Australian JORC standards

-

Valmin code

-

Canadian NI43-101 standards

04

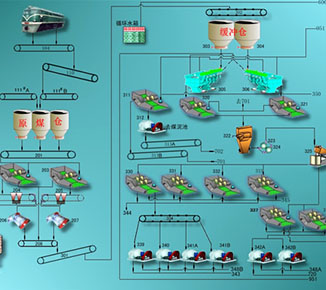

Equipped with Digital Tools for Collaborative Mine Design

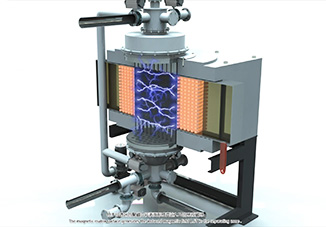

In addition, it also provides design services such as project application, scheme renderings, and review center design, and applies VR technology, AR technology, naked-eye 3D technology, and 720-degree panoramic mineral processing plant technology to mineral processing plant equipment display, mineral processing plant panoramic display, local design display, etc., creating more favorable conditions for automated and intelligent design.

Guote uses professional digital design tools such as SolidWorks 3D design and the PDM design management system for mine design. This not only facilitates collaboration within the design team and ensures the accuracy of the design plan, but also improves design efficiency, optimizes the design process, and avoids repeated revisions of the design plan. Furthermore, Ansys finite element analysis software and EDEM discrete element simulation analysis software are used for parametric modeling and design, facilitating data sharing and exchange, enabling the comparison and optimization of multiple design options and ensuring the feasibility and implementability of the final design plan.

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516