Installation and Commissioning

In the installation and commissioning phase, Guote adheres to the principle of prioritizing client interests and provides comprehensive installation and commissioning services. Guote is responsible for all tools, materials, and personnel required for installation and commissioning, and the client awaits the final results.

-

Installation and commissioning site

-

Guote professional Installation and Commissioning Project Departments handle equipment installation and process commissioning year-round, both domestically and internationally. They have accumulated rich practical experience and possess the capability to undertake over 25 installation and commissioning projects simultaneously, showcasing Guote professional strength and efficient execution.

Guote Installation and Commissioning team encompasses all aspects of mine EPC projects, including Mineral Processing Tests, Mineral Processing Technology, Equipment Selection, Mine Design, Equipment Customization, Equipment Installation, and Process Commissioning. The technical personnel in each segment fully understand the actual conditions of mining projects and work collaboratively to ensure the smooth progress of mining projects. In the later stages of each mining project's Installation and Commissioning, Guote EPC Project Engineering Department conducts Operation Training, Maintenance and Repair Training, and Emergency Response Training on-site for the client employees, ensuring the smooth delivery of the mining project.

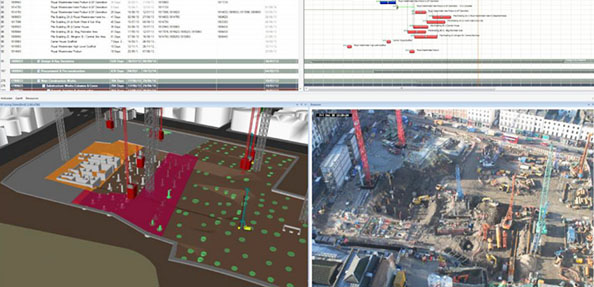

Guote advanced 3D design software to implement modular and modular designs for equipment, non-standard components, pipelines, and more. In the production workshop, Guote has developed various processing fixtures and modular modules, achieving standardized production based on modular and modular designs. Furthermore, by simulating the installation process and integrating drawings with BIM (Building Information Modeling), Guote has broken through traditional installation process management methods. This allows for real-time monitoring of project construction dynamics, precise management of installation information, and control of project progress, further enhancing its ability to manage the installation and commissioning process. Digital installation guidance makes the overall installation and commissioning of the production line more convenient.

-

3D Modular Design

-

Synchro 4D Progress Management

Technical Training

Guote is committed to ensuring the stable operation of mine projects by providing Technical Training, Equipment Operation Training, Production Management Training, Maintenance Training, and Safety Protection Training, helping clients build their technical teams.

Meeting Standards and Achieving Production

Guote comprehensive services for Meeting Standards and Achieving Production include achieving the agreed Recovery Rate, realizing the designed Production Capacity, meeting the agreed Product Quality requirements, aligning Consumption Indicators with agreed standards, effectively controlling Production Costs, and ensuring stable operation of Process Equipment. To achieve these goals, Guote has established a scientific and efficient assessment system, ensuring that each EPC+M+O project can be completed in an orderly manner according to standardized, procedural, and institutional methods.

The key assessment criteria for EPC+M+O projects are on-time delivery, compliance with standards, and achieving full production capacity. With over 10 years of experience in comprehensive mining services and over 200 EPC+M+O projects underway, Guote is able to reliably achieve these goals.

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516