Mineral Analysis Laboratory

After more than 10 years of intensive practice, Guote Mining Equipment Mineral Analysis Laboratory has accumulated solid expertise and rich practical experience. With CNAS international accreditation and a first-class industrial-grade pilot plant, it successfully completes nearly 100 experimental research projects annually, achieving internationally advanced experimental capabilities.

01

Tailoring Technical Solutions for Each Mine with Innovative Thinking

At Guote Mining Equipment, we uphold an innovative philosophy and tailor our technical solutions to each mineral. Before embarking on a research project, we conduct comprehensive pre-conference discussions to ensure the effectiveness of our solutions. We apply innovative thinking to develop experimental plans for each ore sample, fully considering and utilizing its unique mineral properties.

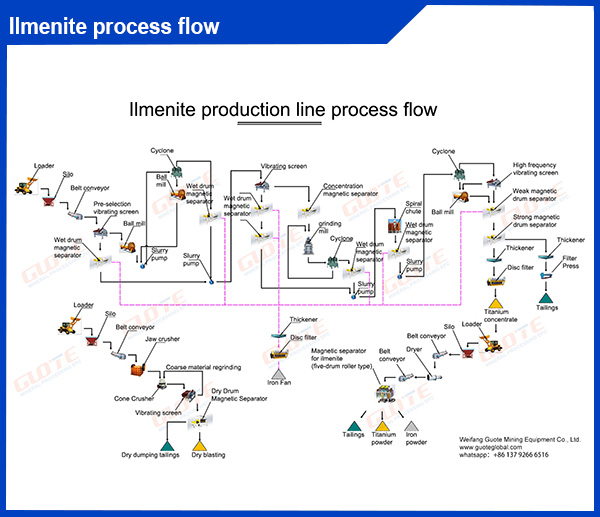

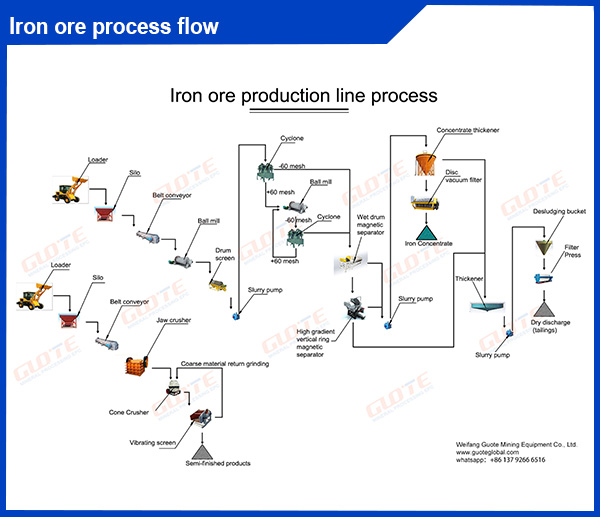

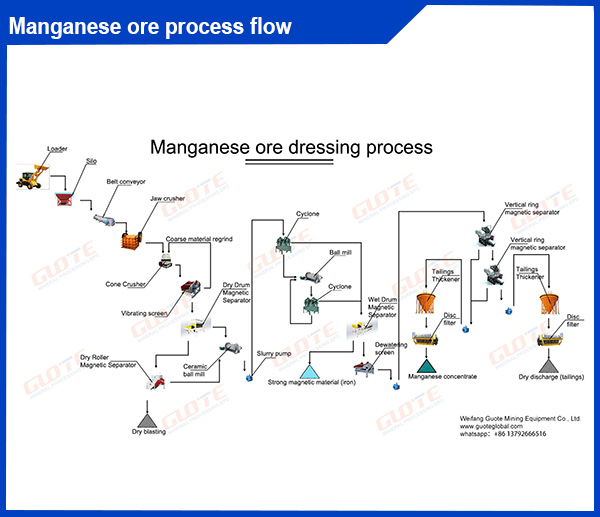

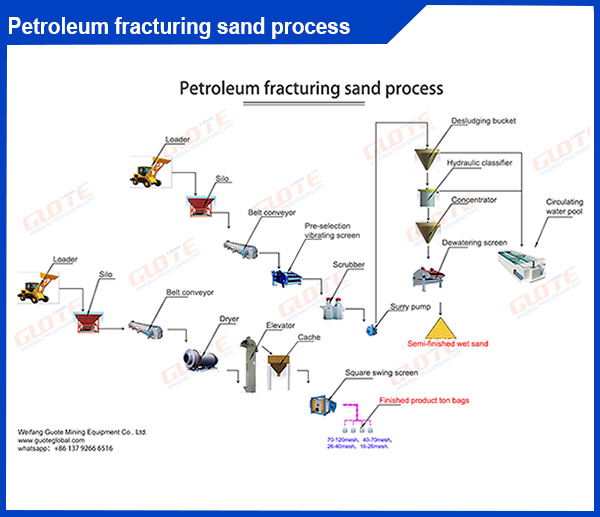

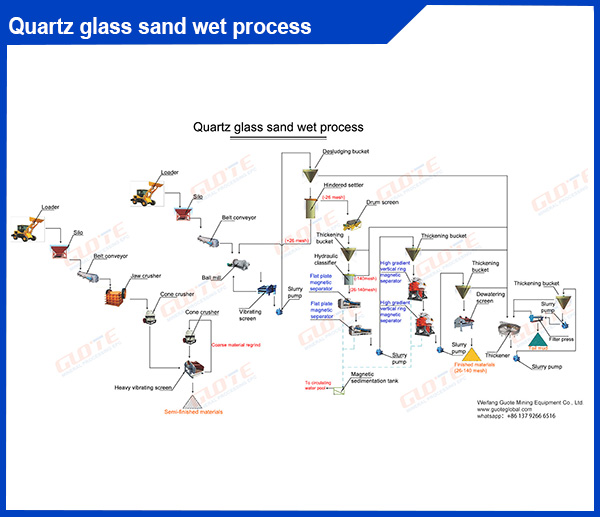

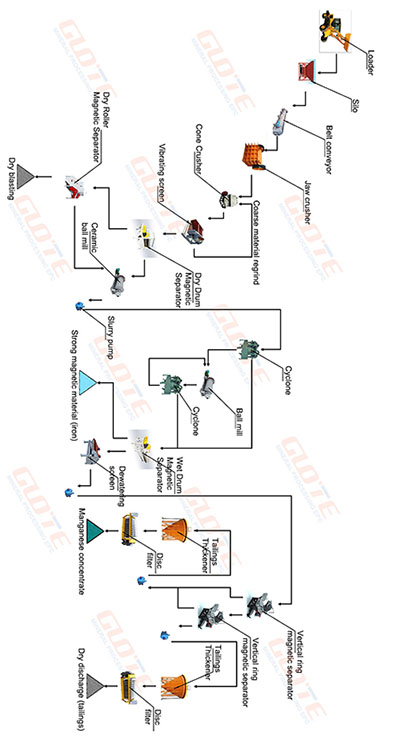

Process flow chart of a manganese iron mine in Russia.

At a large manganese ore processing plant in Russia, the plant's mineral composition (e.g., coexistence of rhodochrosite, pyrolusite, and psilomelane), fine particle size distribution, and high impurity levels led to three key processing challenges: sludge formation interfered with separation, recovery of fine-grained manganese ore was low, and deep removal of phosphorus and iron impurities was difficult. This required a targeted production line design, and the Guote Mineral Analysis Laboratory issued a detailed report based on this situation.

When receiving similar mineral samples for testing, the Guote Mineral Analysis Laboratory developed a detailed plan before and during the testing process, forming the following mineral processing process:

Innovation Point A:

Multi-Mineral Adaptive Sorting System: Utilizes a vertical ring high-gradient magnetic separator with segmented field strength settings to overcome recovery gaps caused by magnetic differences in coexisting minerals. A combined flotation column and mechanical flotation circuit is deployed to achieve precise separation of complex minerals.

Innovation Point B:

Ultra-Fine and Full-Size Recovery Technology: An innovative high-pressure pulse desludging and carrier flotation coupling process enhances fine particle capture through the hydrophobic agglomeration effect. High-precision suspended cone chutes are deployed to fill the gaps in separation achieved by traditional equipment.

Innovation Point C:

Iron-Phosphorus Impurity Deep Removal System: Builds a metallurgical-mineral processing synergistic impurity removal chain to improve subsequent magnetic separation iron removal rates. Innovative magnetic-gravity-flotation concentrate blending allows for the scientific blending of magnetic, gravity, and flotation concentrates with varying impurity characteristics according to metallurgical requirements.

Process flow chart of a manganese iron mine in Russia

For complex multi-ore testing involving diverse ore properties and multiple mining locations, Guote began with representative ore sampling and developed a representative sample collection method:

Mining capacity planning and design – sampling – testing of various sample combinations – primary sample testing and auxiliary sample verification testing – final beneficiation recommendation – design – construction – mining according to the mining capacity design – ore allocation at designated locations in the beneficiation plant – beneficiation production.

02

Providing Accurate Experimental Research for over 30 Types of Minerals

The Guote Laboratory is equipped with modern, advanced equipment, including crushing, fine grinding, vertical ring magnetic separation, flat plate magnetic separation, drying, spectrometers, atomic fluorescence spectrometers, atomic absorption spectrometers, infrared mineral analysis and testing, as well as a comprehensive suite of auxiliary equipment.

The laboratory features rock and mineral identification, grinding work index testing, intelligent laser particle size measurement, as well as gravity separation, magnetic separation, flotation, cyanide leaching and adsorption, bacterial oxidation, acid leaching, specialty mineral processing, heap leaching, tailings thickening, and dry separation, enabling comprehensive experimental research on various mineral processing methods.

The types of minerals served include more than 30 types of ores such as manganese, titanium, iron, lithium, quartz, graphite, chromium, zirconium, vanadium, tungsten, molybdenum, antimony, tin, feldspar, fluorite, andalusite, barite, and phosphate.

03

Equipped with First-class Comprehensive Utilization of Minerals Test and Pilot Center

The Guote Mineral Comprehensive Utilization Pilot Plant Center, occupying approximately 1,500 cubic meters, aims to be a world-class pilot plant. Equipped with full-scale industrial testing equipment and equipped with mobile workstations, the center provides researchers with cutting-edge research opportunities. Collaborating with numerous universities to establish an industry-university-research partnership, the center is dedicated to resolving current technical challenges in the mining industry, promoting the comprehensive utilization of minerals, and striving to become a leading center for mineral processing research.

In addition to necessary crushing, screening, grinding, classification, dewatering, and filtration equipment for routine testing, the center is also equipped with gravity separation, washing, flotation, chemical mineral processing, magnetic separation, electric separation, and color sorting test equipment. These devices and processes have been innovatively improved and developed based on actual mineral separation needs.

04

Special Departments Ensure Achievement of Test Indicators

Guote has established a dedicated solution commissioning department to ensure that all technical indicators, including mineral processing tests, laboratory testing, and equipment commissioning, meet agreed standards. The team seamlessly integrates experimental research, mine design, and on-site commissioning to help clients achieve the expected recovery rates for their mineral projects, ensure that all process indicators meet requirements, and guarantee stable operation of the mineral processing plant, thereby maximizing the overall benefits of the mineral.

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516