Intelligent Mine Equipment Production Center

The Guote Mining Equipment Manufacturing Center uses industrial Internet and Internet of Things technologies to build a technology-driven factory, and is committed to building a benchmark production base in the mining machinery industry and achieving full coverage of 5G Internet of Things.

The Guote Mining Equipment Manufacturing Plant, covering approximately 80,000 square meters, is capable of producing large-scale mining machinery, including vertical ring magnetic separators with a diameter of 5 meters. The plant boasts over 20 cranes in various sizes, including 100-ton, 50-ton, 32-ton, and 16-ton capacity, as well as over 500 pieces of large, medium, and small processing equipment, including CNC floor-standing boring and milling machines, gear hobbing machines, CNC double-column vertical lathes, floor-standing lathes, CNC gantry milling machines, top-roller universal plate rolling machines, laser cutting machines, and welding machines.

01

Strong Equipment Manufacturing Capability

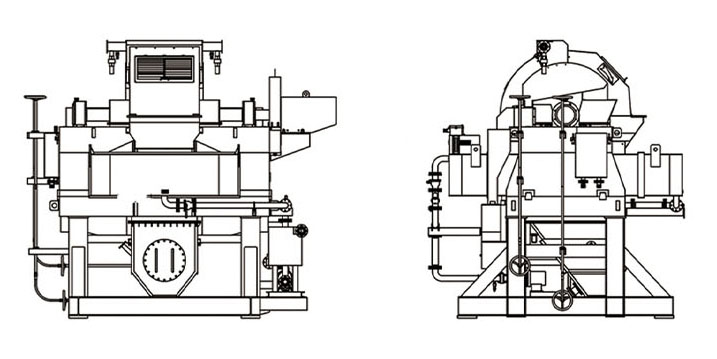

Guote boasts over 500 types of mining, mineral processing, and smelting equipment, providing a complete range of main and auxiliary equipment for mines with daily production capacity of up to 30,000 tons. The company also manufactures large-scale mining machinery, including vertical ring magnetic separators with a diameter of 5 meters.

The production base boasts hundreds of machining equipment, including lathes, milling machines, planers, grinders, boring machines, drillers, stamping machines, welding machines, roller mills, and shearing machines. Furthermore, the company has independently developed specialized machining equipment for vertical ring magnetic separators, bearing and pulley assembly and disassembly equipment, and over ten specialized mining machinery processing equipment. Furthermore, a dedicated sandblasting and painting shop provides rust and corrosion protection for mining equipment, ensuring quality and extending its service life.

In addition, Guote is also equipped with a full set of CNC production equipment, including digital laser cutting machines, automatic welding robots, CNC floor-standing boring and milling machines, CNC double-column vertical turning and milling machines, CNC gear hobbing machines, CNC lathes, CNC gantry milling machines, etc., continuously advancing the company's digital production process.

02

High Standards of Equipment Performance and Quality

The company has obtained many international quality certifications, including EU CE certification, Canadian Welding Bureau CSA standard certification, AWS welder qualification certification, ISO9001:2015 international quality management system certification, ISO14001:2015 environmental management system certification, ISO45001:2018 occupational health and safety management system certification, and high-tech enterprise certification, to ensure that products are manufactured in accordance with international standards.

-

Canadian Welding Bureau CSA Standards Certification

-

ISO 9001: 2015 Quality Management System Certification

-

CE Certification

03

High Standards of Accessory Matching Capability

For customers with high product requirements, Guote provides motors, reducers, bearings, and electrical components from internationally renowned brands. For example, motors are from Dunkermotoren, ABB, and Siemens; reducers from SEW, Harmonic Drive, and FLENDER; bearings from SKF, FAG, and NTN; and electrical components from Siemens, Schneider, and Legrand.

- Motor 电动机

- Reducer 减速机

- Bearing 轴承

- Electrical component 电器元器件

- Diesel generating set 柴油发电机组

- Wire and cable 电线电缆

Product R&D Center

The Guote Mining R&D Center is responsible for the research, development, design and improvement of equipment. Our technical staff provides customers with the equipment they need based on the specific equipment requirements of their mining projects. We also provide a seamless one-stop service of "ore dressing test, ore dressing process, equipment selection, mine design, and equipment customization."

01

Innovative Mechanical R&D Capabilities

The Guote Mining R&D Center actively engages in industry-university-research collaborations with renowned universities and research institutions, including China University of Mining and Technology, Shandong University of Science and Technology, and Qilu University of Technology. In equipment R&D, the team consistently focuses on customer pain points, adheres to a lean equipment R&D philosophy, and aims to improve equipment performance and efficiency. By integrating lean process flows, the team aims to increase production efficiency, reduce energy consumption, and extend equipment's stable operating time, continuously advancing the development of large-scale intelligent mining equipment.

02

Strong Mechanical Design Capabilities

The Guote Product R&D Center brings together over 10 technical experts with extensive experience in mining machinery design and project implementation. Closely integrating the practical needs of each stage of the mining EPCM process, the center has deeply optimized and innovatively improved over 80% of commonly used mining equipment. By continuously adjusting and optimizing equipment parameters and developing digital interfaces, the center has achieved automated control and data visualization for mining equipment, bringing substantial improvements to mining production and successfully applying for over 100 patents.

Automation and Intelligent Product R&D and Manufacturing Base

Leveraging its leading intelligent equipment manufacturing capabilities, Guote is committed to providing automated, information-based, intelligent, and unmanned solutions for mines. We are also actively promoting the integration of advanced technologies such as the Internet of Things and virtual reality to build a smart mining ecosystem. We are also actively promoting the application of cutting-edge technologies such as big data, AI intelligent analysis, 5G, and edge computing in mining. We provide clients with comprehensive smart mine planning, detailed design, and EPC+M+O implementation services, striving to create smart and green mines and promote the efficient development of the mining industry.

Guote Mining Equipment focuses on providing design, research and development, integration and construction services for mining automation, intelligence, intelligence and informatization. It can provide overall automation and intelligent solutions and integrated EPCM general contracting services for electrical, instrumentation, automation and weak current engineering.

R&D base for multi-type and multi-specification magnetic separation equipment

Guote specializes in the development of magnetic media separators. These separators utilize external current excitation to generate a strong background magnetic field, which is then converted into an extremely high magnetic field gradient by a specially shaped soft magnetic medium filling the separation chamber. This powerful magnetic force makes it one of the most effective methods for separating weakly magnetic and fine-grained minerals, and is widely used in mineral processing, material purification, and environmental protection. Guote has applied for 15 patents for this equipment, including eight invention patents and seven utility model patents.

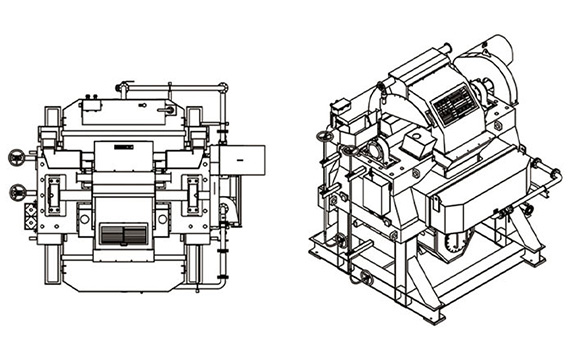

Guote has also innovatively developed a five-roller magnetic separator that can separate and purify titanium concentrate, iron concentrate, and impurities in a single operation, increasing ore grade to 40% to 45%.

Guote combines a vertical ring magnetic separator with a flat plate magnetic separator for multiple separations, creating a new solution for mineral purification and grade improvement.

Sieve plate technology and product development

In the mineral processing process, screen plates are core components of screening equipment, and their performance directly impacts screening efficiency, processing capacity, product particle size, and equipment life. Based on the characteristics of different minerals, Guote Mining Equipment has continuously researched and implemented new products, including perforated screen plates, woven metal screens, bar screen plates, polyurethane screen plates, and rubber screen plates. In abrasive, clog-prone, and humid mineral processing environments, polyurethane screen plates have become the preferred choice for many applications due to their exceptionally long life, excellent anti-clogging properties, and modular design for easy maintenance.

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516