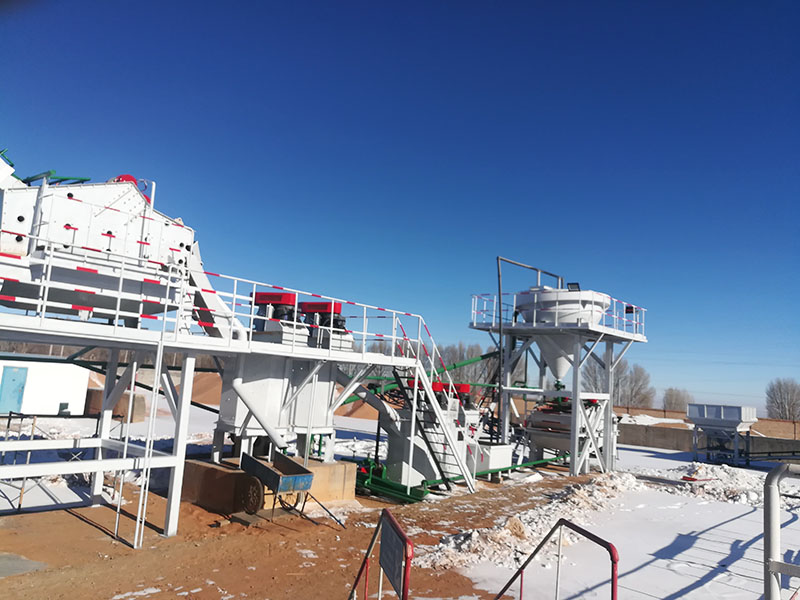

Philippines 500t/d Oil Fracturing Sand Processing Plant

The client's raw ore was natural sand with a 10% mud content, 5-10% coarse material, and 3-5% washed sand.

During the construction of the concentrator, Guote's technicians consistently adhered to professional technical standards, completing every task from design to construction, and smoothly advancing the project.

GUOTE SOLUTION

-

1

Scrubbing and Desludging: The material is fed via a belt feeder (with a weighing device) to a vibrating screen for screening. The screened material then enters a spiral ore washer for initial washing and desludging. After pre-washing, the material enters a scrubbing machine for secondary scrubbing. The scrubbed slurry is pumped into the desludging hopper on the grading tower, where it separates sand, mud, and impurities, reducing the mud content of the raw ore and balancing the slurry.

-

2

Screening and Classification: The desludged material enters a hydraulic classifier, which separates fine sand below 140 mesh (0.1 mm). This reduces subsequent drying and screening costs and increases the yield of subsequent processes.

-

3

Drying and Screening: After dewatering the material through the dewatering screen, it enters a dedicated Guote quartz sand dryer, where it is efficiently and quickly dried. The material then enters a screening system, where qualified material is screened and packaged for storage.

PROJECT RESULT

This project uses an intelligent control system to manage the entire production line. Guote provides automation service solutions, including automation design, customized automation equipment, intelligent control systems, and video surveillance systems. This achieves coordinated and optimized control at all stages of operation, significantly improving production efficiency.

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE