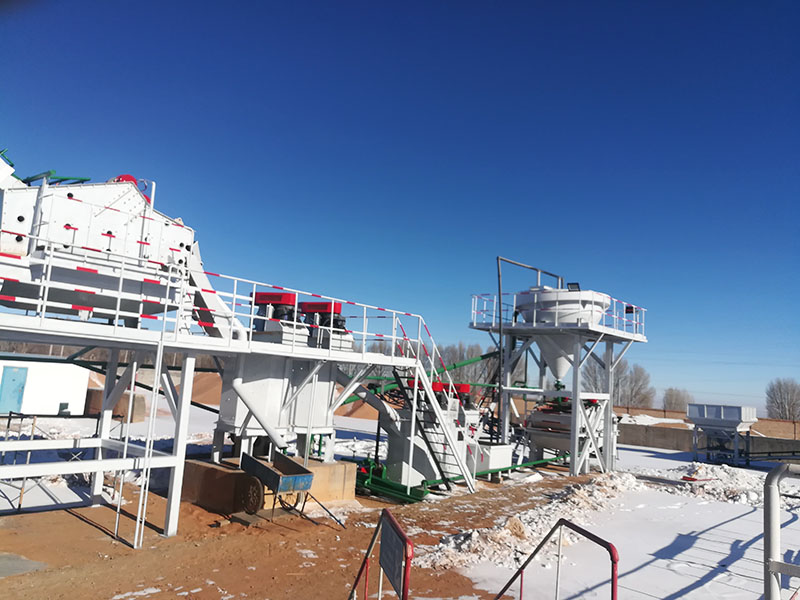

Inner Mongolia 800t/d Oil Fracturing Sand Processing Plant

The raw ore was natural desert sand, containing 10% mud and magnetic materials that affected acid solubility.

The client consulted Guote for general contracting services for a mineral processing plant. Guote provided construction and engineering design, including expertise in process engineering, civil engineering, electrical engineering, and water supply and drainage. After detailed discussions, the client learned about Guote's high-efficiency, low-consumption analytical electrolysis system and was impressed by its advantages. The client successfully reached a cooperation agreement with Guote to assist in the construction of the production line.

GUOTE SOLUTION

-

1

Scrubbing and Desludging: The material is fed via a belt feeder (with a weighing device) to a vibrating screen for screening. The screened material then enters a spiral ore washer for initial washing and desludging. After pre-washing, the material enters a scrubbing machine for secondary scrubbing. The scrubbed slurry is pumped into the desludging hopper on the grading tower, where it separates sand, mud, and impurities, reducing the mud content of the raw ore and balancing the slurry.

-

2

Screening and Classification: The desludged material enters a hydraulic classifier, which separates fine sand below 140 mesh (0.1 mm). This reduces subsequent drying and screening costs and increases the yield of subsequent processes.

-

3

Magnetic Separation and Dewatering: The material exiting the hydraulic classifier is of acceptable particle size. This acceptable particle size enters the magnetic separation stage. Using a plate magnetic separator with a magnetic field strength of 10,000-12,000 GS, all iron impurities and some weakly magnetic iron are completely removed. Finally, the qualified materials are dehydrated by the dehydration screen and then put into the stockpile shed to wait for drying.

PROJECT RESULT

The turbidity and drying and screening costs of the main product, finished sand, have been reduced, meeting expected requirements. After processing, the ore meets the requirements for fracturing sand.

The entire project features high construction efficiency, a short construction period, and rapid commissioning. The plant has achieved its goals, operating efficiently and stably throughout the project and has been successfully put into operation. This is a comprehensive recognition of the client's professional expertise and another successful EPC case for Guote.

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE