India 1,800t/d Iron Ore Processing Plant

The client's raw ore consisted of magnetite and contained weakly magnetic hematite.

Guote developed a comprehensive process for this complex, weakly magnetic ore. It used a wet drum magnetic separator for the first magnetic separation and a wet high-field magnetic separator for the second magnetic separation.

GUOTE SOLUTION

-

1

Based on the ore's characteristics, such as size, hardness, and impurity content, 1-3 stages of crushing are selected to reduce the ore's particle size. The ore in the silo is fed evenly and quantitatively by a vibrating feeder into a jaw crusher for primary crushing, which crushes the ore to a size of 60-80 mm. The crushed ore then enters a cone crusher for further crushing to a particle size of 10-20 mm. Ore that does not meet this particle size is screened by a vibrating screen and then returned to the cone crusher for secondary crushing. Ore particles that meet the required particle size are then conveyed to a wet ball mill via a conveyor belt for grinding.

-

2

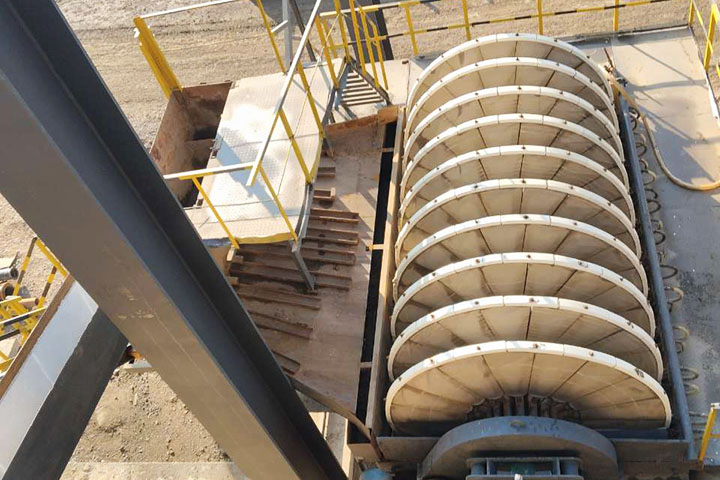

Under the rotation of the ball mill, the ore particles are ground to a finer size than 60 mesh. Coarse particles that do not meet this size are classified by a cyclone and then returned to the ball mill for secondary grinding.

-

3

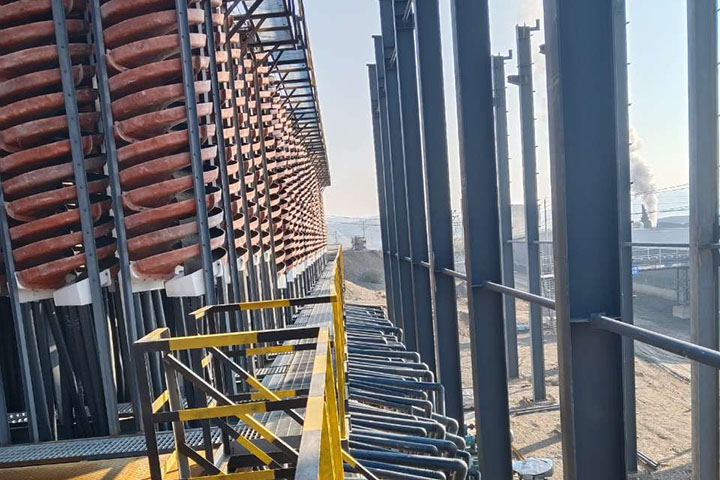

The qualified ore slurry is transported via a pipeline to the magnetic separation and impurity removal stage. First, the slurry enters a wet high-intensity magnetic drum separator for purification. Because the material contains hematite, the impurity-removed slurry then enters a GTLH vertical ring high-gradient magnetic separator for secondary purification. This equipment, with a background field strength of 1.0T and an induction magnetic field of 1.5T, completely separates fine-grained impurities from the slurry. The pulsation system equipped in the vertical ring high-gradient magnetic separator significantly improves the precision and grade of the iron ore.

-

4

The resulting iron ore concentrate is conveyed through a pipeline to a thickening tank containing a thickener. The concentrated slurry settles to the bottom of the tank and is collected by a thickening rake at the discharge port. It then passes through a vacuum filter for dewatering. The microporous filter separates the solid and liquid content of the iron ore slurry. The dewatered water can be recycled as beneficiation water. The iron ore concentrate is then transported by conveyor to the finished product storage yard.

PROJECT RESULT

The grade of first-stage iron concentrates was 65.06%, the yield of first-stage iron concentrates was 31.00%, the recovery of first-grade iron concentrates was 54.75%; the grade of second-stage iron concentrates was 51.95%, the yield of second-stage iron concentrates was 5.00%, the recovery of second-grade iron concentrates was 7.05%.

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE