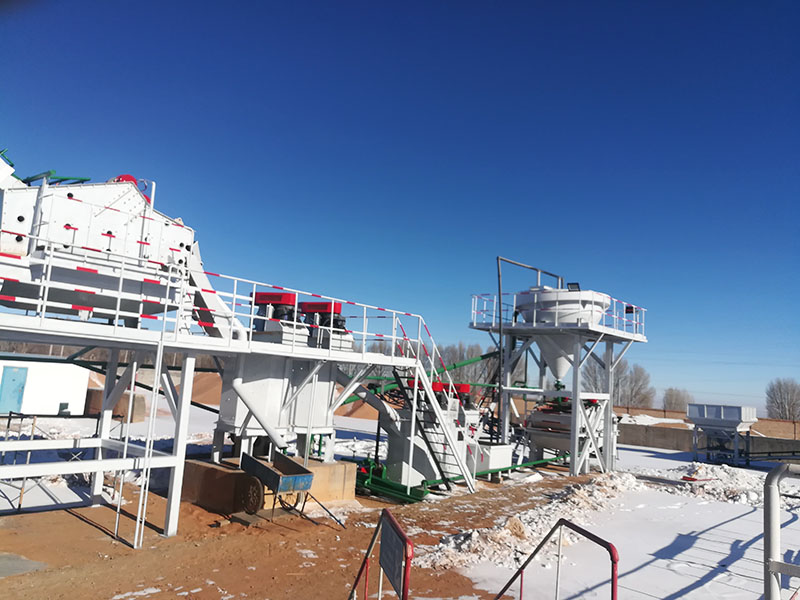

Heilongjiang 500t/d Petroleum Proppant Processing Plant

The client's raw ore was natural sand, containing 15-20% mud, 1% large rocks, 3-5% coarse sand, and weed roots.

To address this situation, our senior mineral processing engineers conducted multiple on-site inspections, collected material from multiple locations, and personally participated in water washing experiments in the laboratory. Through extensive analysis of experimental data, they led a professional team to continuously refine the process plan, ultimately developing a simple, reliable, and efficient solution for the client, tailored to the requirements of the frac sand industry.

GUOTE SOLUTION

-

1

Classification: The raw sand is pre-screened through the buffer hopper and the feeder, and the coarse materials are screened out (reducing the pressure of subsequent equipment). The fine materials enter the scrubbing machine for mud and sand separation. After separation, the materials enter the slurry pool and are then pumped into the desludging bucket on the grading tower through the slurry pump. The desludging bucket desluds to reduce the mud content of the product. The desludged product enters the hydraulic classifier. The hydraulic classifier is mainly used to separate 140 Fine products (adjustable) are separated by gravity from products with a mesh size of 140 or larger. The +140 mesh material passes through a thickening hopper to adjust the slurry concentration before entering a dewatering screen. The dewatering screen primarily reduces the moisture content of the raw ore, separating the water and sand, and producing a semi-finished product with a particle size of +140 mesh. The material is then naturally air-dried to drain the water and control the moisture content to less than 10%.

-

2

Drying: The material then passes through a buffer silo and conveyor belt into a dryer, where the sand is dried to meet moisture requirements.

-

3

Screening: After drying, the material passes through a bucket elevator and a buffer hopper and enters a swing screen (linear screen) for screening into different mesh sizes: 16-20 mesh, 20-40 mesh, 40-70 mesh, 30-50 mesh, and 70-140 mesh. The qualified material is then packaged in ton bags.

PROJECT RESULT

After pre-selection, scrubbing and desludging, grading, drying, and screening, the raw ore fully meets the specifications for frac sand.

Currently, the project is operating stably, and the economic indicators and benefits of the concentrator have met the client's ideal expectations. The client sent a “letter of appreciation” to Guote, expressing their appreciation for the thorough supervision and meticulous professionalism of Guote Mining Equipment's technical engineers. We commend Guote Mining Equipment for its high sense of responsibility and sincerely hope that in future collaborations, we will work closely together to achieve greater success!

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE