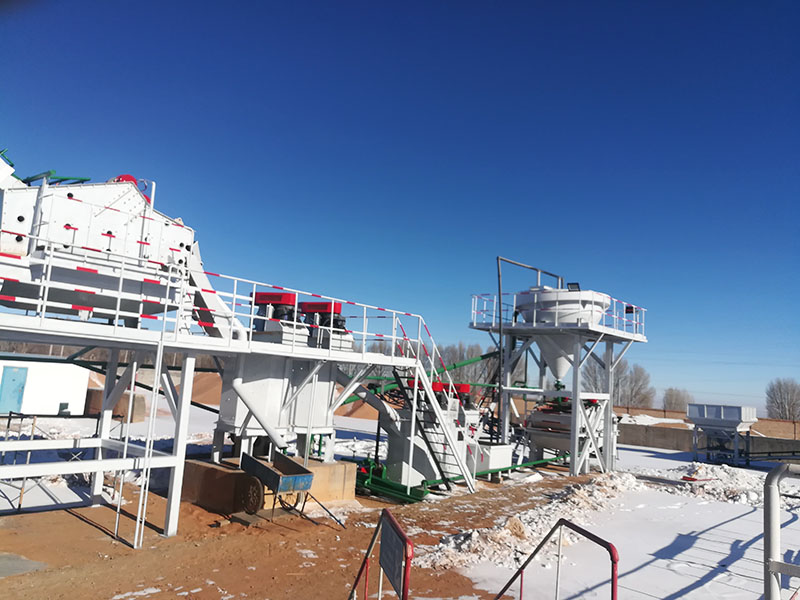

Kazakhstan 1,000t/d Oil Fracturing Sand Processing Plant

The client's original ore is natural aeolian sand with a high mud content.

In view of the original ore conditions and environmental factors, the Guote Technology Design Department provides the client with a tailor-made product production line general contracting, operation and guidance.

GUOTE SOLUTION

-

1

Scrubbing and desludging: The raw sand passes through the buffer hopper, the belt scale, and the pre-selection screen to screen out the coarse materials. The finer materials enter the scrubber for mud and sand separation. After separation, the materials enter the slurry pool, and then are pumped into the desludging bucket on the grading tower through the slurry pump. The desludging bucket performs secondary desludging to reduce the mud content of the materials.

-

2

Grading and dehydration: The desludging materials enter the hydraulic classifier. The hydraulic classifier mainly separates the fine materials of 140 mesh (adjustable) and finer products of 140 mesh by gravity principle. The +140 mesh materials are adjusted through the concentration bucket and then enter the dehydration screen. The dehydration screen is to reduce the moisture content of the raw ore, separate the water and sand, and produce the semi-finished products with the qualified particle size requirements of +140 mesh. After natural drying, the materials are drained and the moisture content is controlled within 10%.

-

3

Drying and screening: The materials in the buffer silo enter the dryer through the conveyor belt to dry the sand until the moisture reaches the standard requirement. After drying, the materials pass through the bucket elevator and the buffer hopper and enter the swing screen (linear screen) for screening with different mesh sizes of 16-20, 20-40, 40-70, 30-50, and 70-140. After screening, the qualified materials are packaged as finished products.

PROJECT RESULT

The project reduced production costs by 10%, exceeding customer expectations by 15%. After pre-selection, scrubbing and desludging, grading, drying, and screening, the raw ore fully met the specifications for frac sand.

According to the specific conditions of the project, Guote strictly implements relevant standards, optimizes the layout of the plant, reduces costs, shortens construction period, and its efficient and energy-saving equipment and perfect process flow have won high recognition from customers.

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE