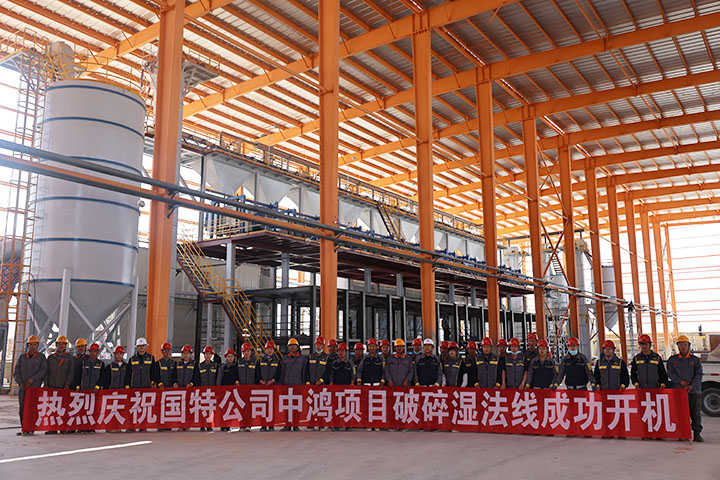

Gansu 3,000t/d Silica Sand Processing Plant

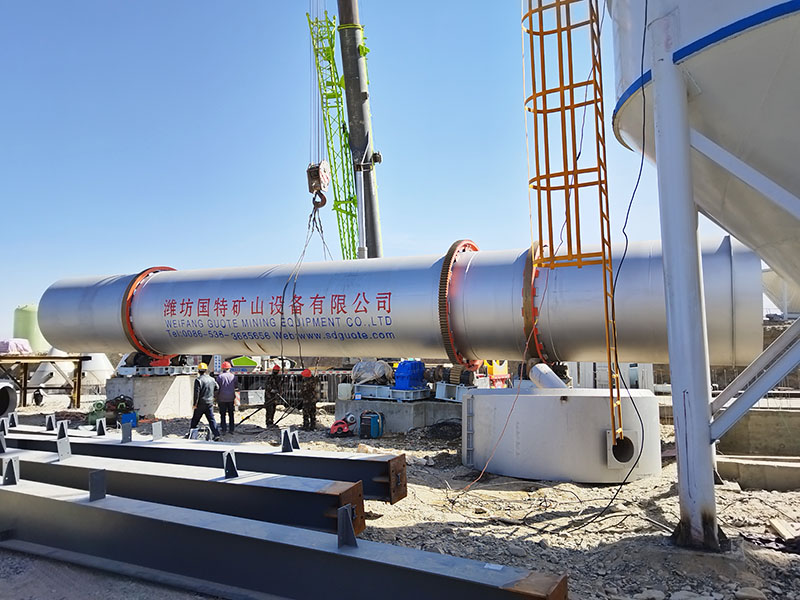

The Gansu project is a mining industry chain service (EPC+O) project undertaken by Guote. Guote exclusively handles the entire project process, from design and research, complete equipment manufacturing and procurement, commissioning and delivery, to mine management and operations.

The original ore consists of vein quartz, with Fe₂O₃ rust films developing along the fissures.

In order to protect the interests of investors, we minimize investment and increase benefits as the main idea. At the same time, we pay attention to the health and safety of operators, emphasize harmonious coexistence with the environment, resource conservation and recycling, high efficiency and energy saving of single machines and unit combinations, and strive to optimize each operation and the entire process.

GUOTE SOLUTION

-

1

Crushing: The raw ore is crushed to the required particle size for sand production using a crusher. The crushing process is generally divided into three stages.

-

2

Grinding: Sand is produced using ball milling. The crushed sandy material enters the ball mill for grinding.

-

3

Scrubbing: After the ball milling process, the material with the required particle size is then scrubbed clean using a desludging device.

-

4

Magnetic Separation: The desludging and scrubbing material is conveyed by a conveyor belt to medium- and high-field strength magnetic separators to remove magnetic impurities. Guote Equipment's flat plate magnetic separator and vertical ring magnetic separator are both independently developed. , with a maximum field strength of up to 2.0T.

-

5

Flotation: Qualified materials after magnetic separation enter the flotation process. The main purpose of the flotation machine is to remove muscovite from the material.

-

6

Pickling: The material enters the acid leaching process to remove surface yellowing and complete deacidification.

-

7

Drying: After deacidification, the material is drained and then dried in a dryer.

-

8

Screening: After thorough drying, qualified products are graded and processed according to the required mesh size.

-

9

Color Sorting: Qualified products pass through a color sorter to remove miscellaneous particles before being packaged and shipped.

PROJECT RESULT

After processing, the raw ore meets the requirements for plate concentrate, reducing production costs by 35% and improving product quality. This exceeded customer expectations by 10%.

The entire plant operates smoothly, equipment performs well, and both beneficiation indicators and economic benefits meet expectations.

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE