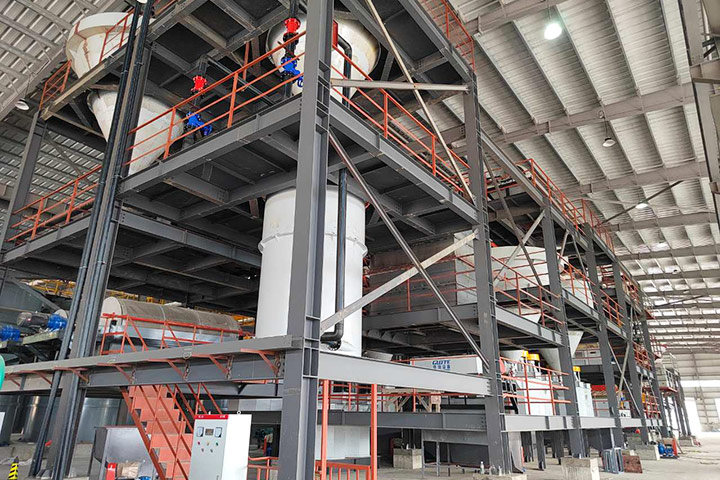

Fujian 3,000t/d Quartz silica sand processing plant

The raw ore consisted of kaolin tailings and 0-8mm quartz sand head material. Kaolin was interspersed in the ore's cracks, resulting in poor dissociation and relatively low beneficiation performance.

To address this situation, Mr. Yang Guoqing, a senior mineral processing engineer, personally planned and designed a construction plan based on the site conditions, selecting the most cost-effective equipment combination for the customer.

GUOTE SOLUTION

-

1

Ore Pre-selection and Impurity Removal: Large particles of debris are removed through screening.

-

2

Scrubbing: After impurity removal, the material enters a scrubber for scrubbing. The resulting slurry is then pumped through a slurry tank to a desludging hopper.

-

3

Desludging: Desludging and impurities are removed in the desludging hopper, and the slurry is piped to a water treatment system for sedimentation.

-

4

Coarse Grain Screening and Grading: The underflow slurry enters a blocked settler and drum screen for screening. The +26 mesh material is returned to the ceramic ball mill through a return pipe for re-grinding. The treated minerals return to the post-scrubbing slurry tank, forming a closed-loop coarse sand production cycle.

-

5

Grading and Fine Sand Collection: The overflow from the blocked settler (-26 mesh slurry) is piped to a thickening hopper and hydraulic classifier; the overflow from the hydraulic classifier (-150 mesh slurry) is collected in a fine sand collection area for drainage.

-

6

Magnetic Separation and Purification: The hydraulic classifier underflow (qualified products with a mesh size of 26-150) is subjected to a medium-magnetic plate magnetic separator to remove mechanical iron. It then passes through a high-magnetic plate magnetic separator (12,000 GS) to remove all mechanical iron and some weakly magnetic iron. Finally, it passes through a vertical ring high-gradient magnetic separator (1.5 T magnetic field, two units connected in series) for electromagnetic iron removal.

-

7

Finished Product Dewatering and Shipping: After magnetic separation, the product is transported to the finished product area via a slurry pump. It is dewatered through a thickening hopper and dewatering screen, then conveyed by a finished product conveyor belt to the finished product area for drainage and ready for shipping.

-

8

Water Treatment and Tailings Sludge Treatment: Water treatment utilizes multi-stage thickening tanks for sedimentation. The underflow sludge is then pumped to a plate and frame filter press via a slurry pump to recover water, forming a sludge cake for subsequent processing.

PROJECT RESULT

From process design to equipment supply and on-site construction, the Guote team managed the entire project, ensuring on-time completion, smooth commissioning, and achieving production targets ahead of schedule.

The finished sand, the main product, meets the requirements for photovoltaic quartz sand, with a yield rate of approximately 80-85%. After stabilizing the ore source, the iron content of the finished sand is within 100 ppm. This exceeded expectations, and after processing, the ore meets the requirements for concentrated sand.

RELATED NEWS

- High-efficiency magnetic separation equipment successfully shipped!

- Repair and maintenance of mining machinery and equipment.

- Introduction to the main application areas of silicon powder

- Process characteristics and process of quartz stone pickling

- Weifang Guote Mining Equipment Co., Ltd.

- What is a magnetic separator? What types of magnetic separators are there?

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE