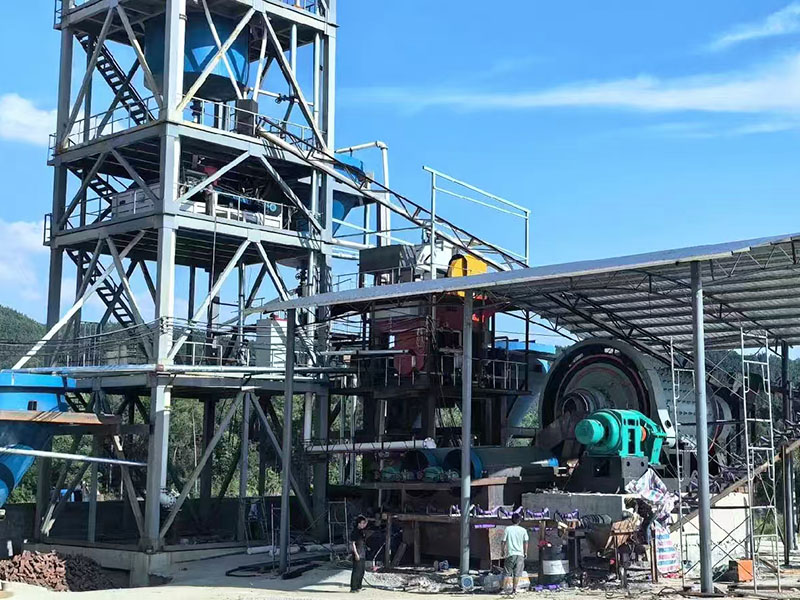

Cambodia Quartz Sand Processing Plant

The original ore consisted of quartz sandstone veins with excessive aluminum content.

To address this situation, Guote provided comprehensive services, including process design, equipment supply, and on-site installation guidance, ensuring the plant's successful commissioning and achievement of production targets. The project utilized a combined classification and magnetic separation process, characterized by a short construction period, low costs, and rapid economic returns.

GUOTE SOLUTION

-

1

Crushing: The raw ore is crushed by a crusher to the particle size required for sand production.

-

2

Grinding: Sand is produced using ball mills, which grind the crushed particles into sand suitable for beneficiation.

-

3

Scrubbing: Multiple scrubbing passes utilize high concentration and high speed to remove aluminum impurities from the sand surface.

-

4

Magnetic Separation: After desludging, the material is subjected to magnetic separation, where it passes through a flat plate magnetic separator or vertical ring magnetic separator to effectively remove magnetic impurities.

-

5

Tailing Water Treatment: A high-efficiency thickener is equipped to collect all waste water for sedimentation treatment. After treatment, the water is returned to the production line for recycling, eliminating any external wastewater.

PROJECT RESULT

Guote provided the client with complete and detailed construction drawings, as well as on-site installation and commissioning services. Leveraging its mineral processing, modern manufacturing facilities, and extensive international project experience, Guote ensured smooth plant construction and a steady ramp-up of production. Guote demonstrated its comprehensive capabilities in design, manufacturing, and EPC service delivery.

Contact Us

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.

guotemining@gmail.com

guotemining@gmail.com  8613792666516

8613792666516

CHAT

CHAT MESSAGE

MESSAGE